Glass plate and method for manufacturing same

A manufacturing method and technology for glass plates, applied in the input/output process of instruments, coatings, data processing, etc., can solve problems such as scratches on the lower surface of the glass ribbon, and achieve the effect of inhibiting the generation of white turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092] Hereinafter, examples of the present invention will be specifically described, but the present invention is not limited to these.

[0093] In this example, a glass plate of a glass material having the following composition was used.

[0094] In mol%, it contains 64.2% SiO 2 , 8.0% Al 2 O 3 , 12.5% Na 2 O, 4.0% K 2 O, 10.5% MgO, 0.1% CaO, 0.1% SrO, 0.1% BaO, 0.5% ZrO 2 Glass plate

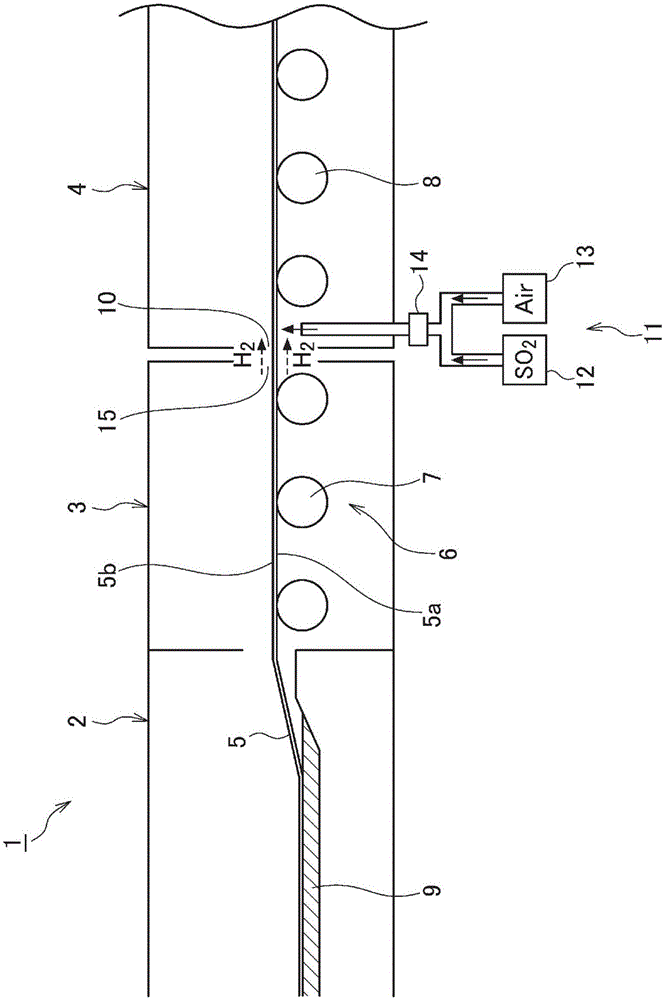

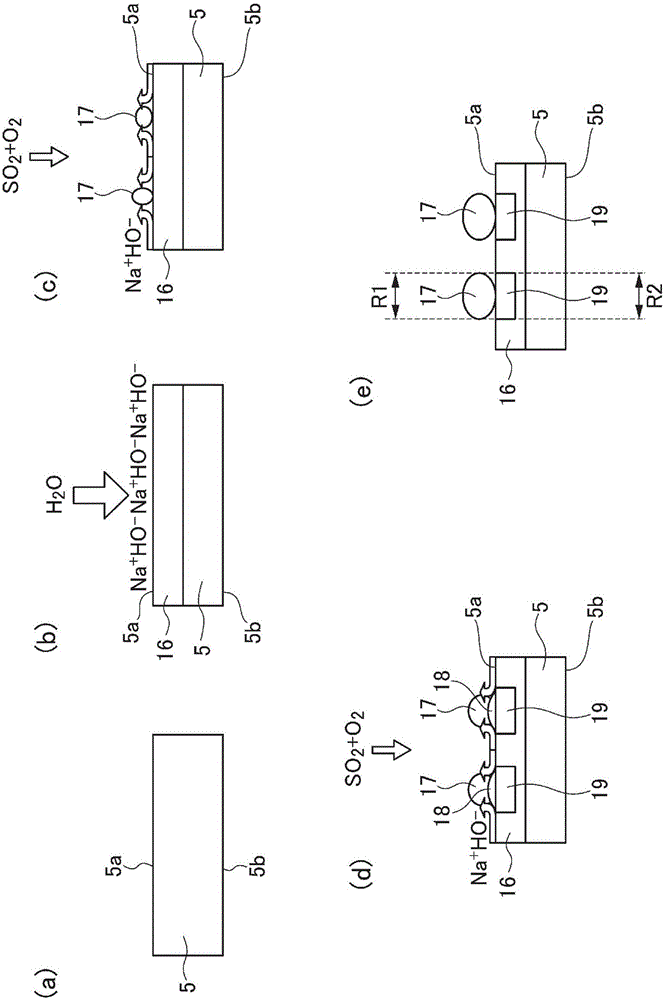

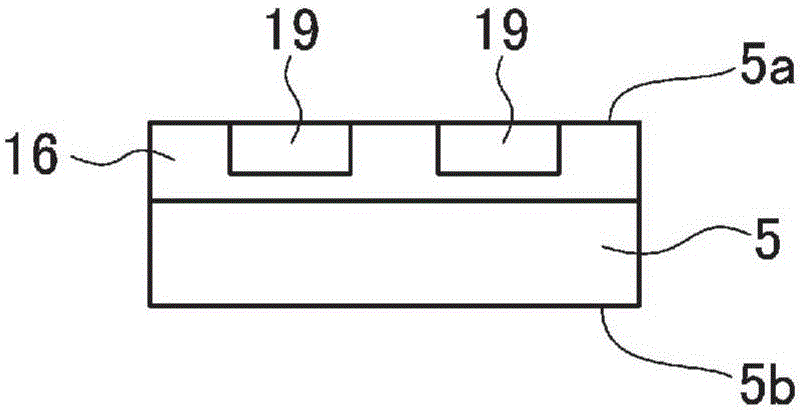

[0095] With the buffer layer forming device 11, the SO2 was removed at the upstream end of the annealing furnace 4 at the supply amount shown in Table 2. 2 And air is supplied to the bottom surface 5a of the glass ribbon 5.

[0096] [Table 2]

[0097]

[0098] It should be noted that although in figure 1 Although not shown in the figure, in the annealing furnace 4 of the present embodiment and the comparative example, five other buffer layer forming devices (downstream buffer layer forming devices) are provided on the downstream side of the buffer layer forming device 11. The five downstream buffer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com