Method for producing internal mold release agent for optical material, internal mold release agent for optical material, and polymerizable composition including the same

A technology of polymerizable composition and internal mold release agent, which is applied in chemical instruments and methods, optics, optical components, etc., can solve the problem of inability to improve the white turbidity of resin, and achieve the improvement of transparency, suppression of white turbidity, and mold release. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

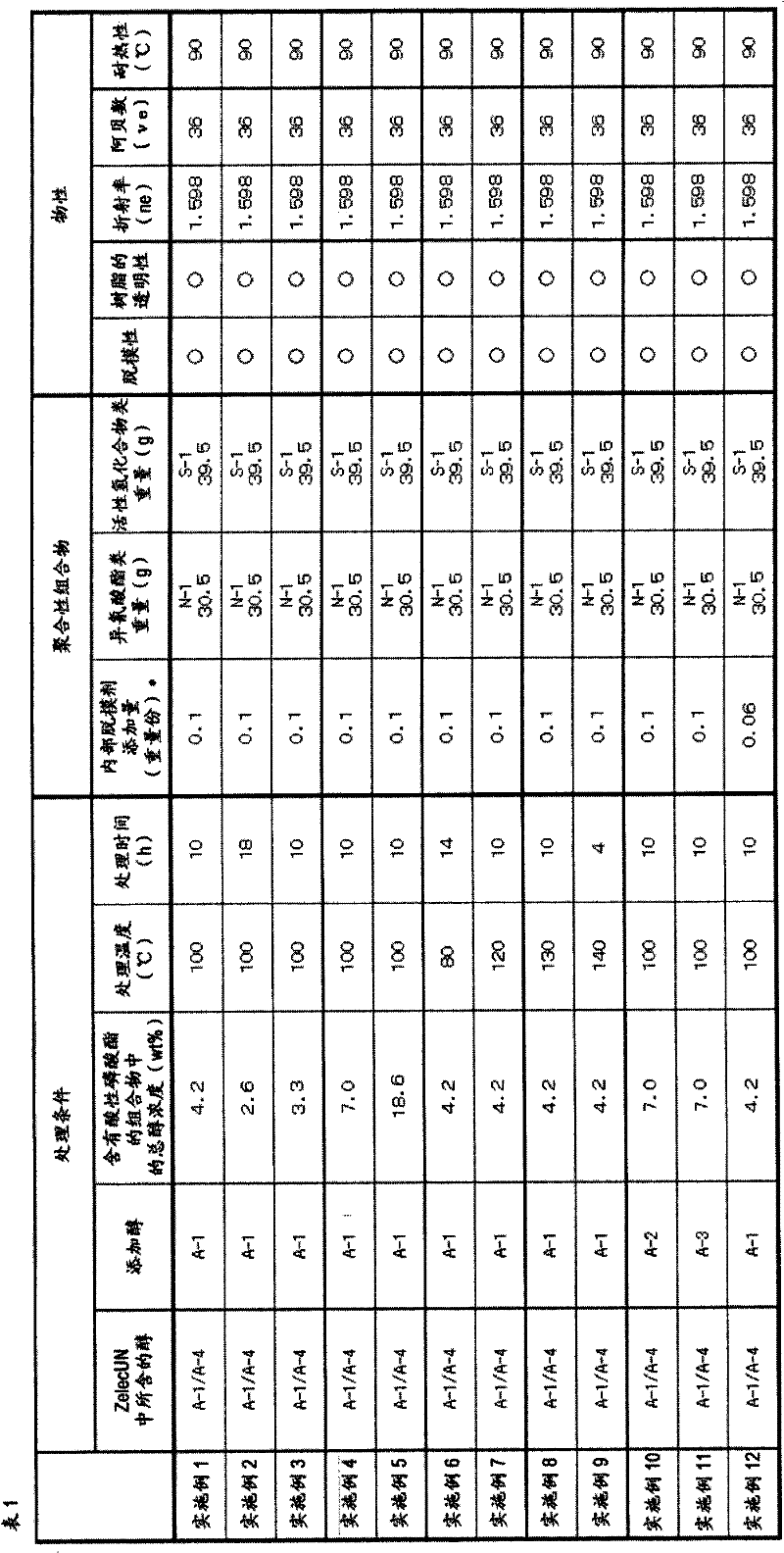

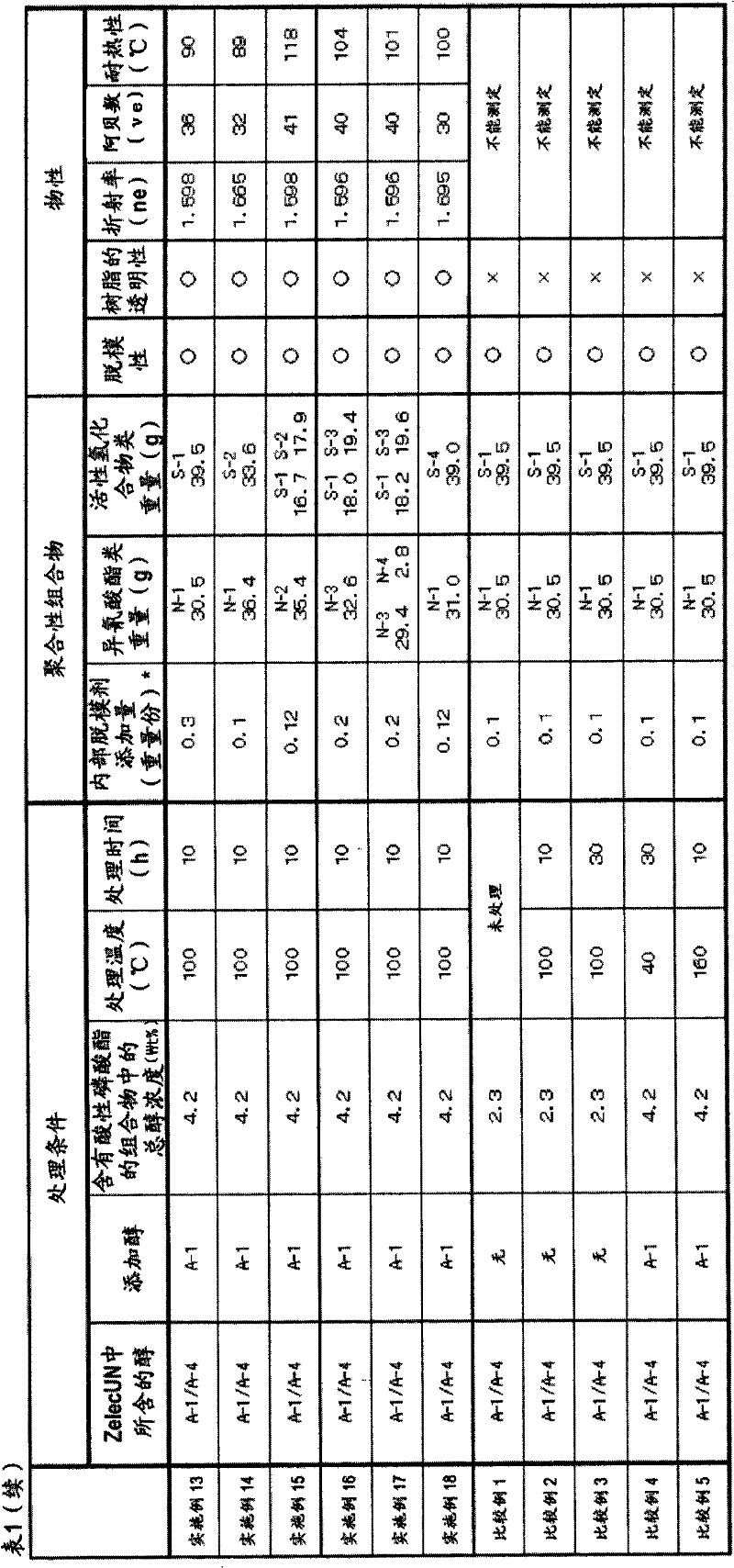

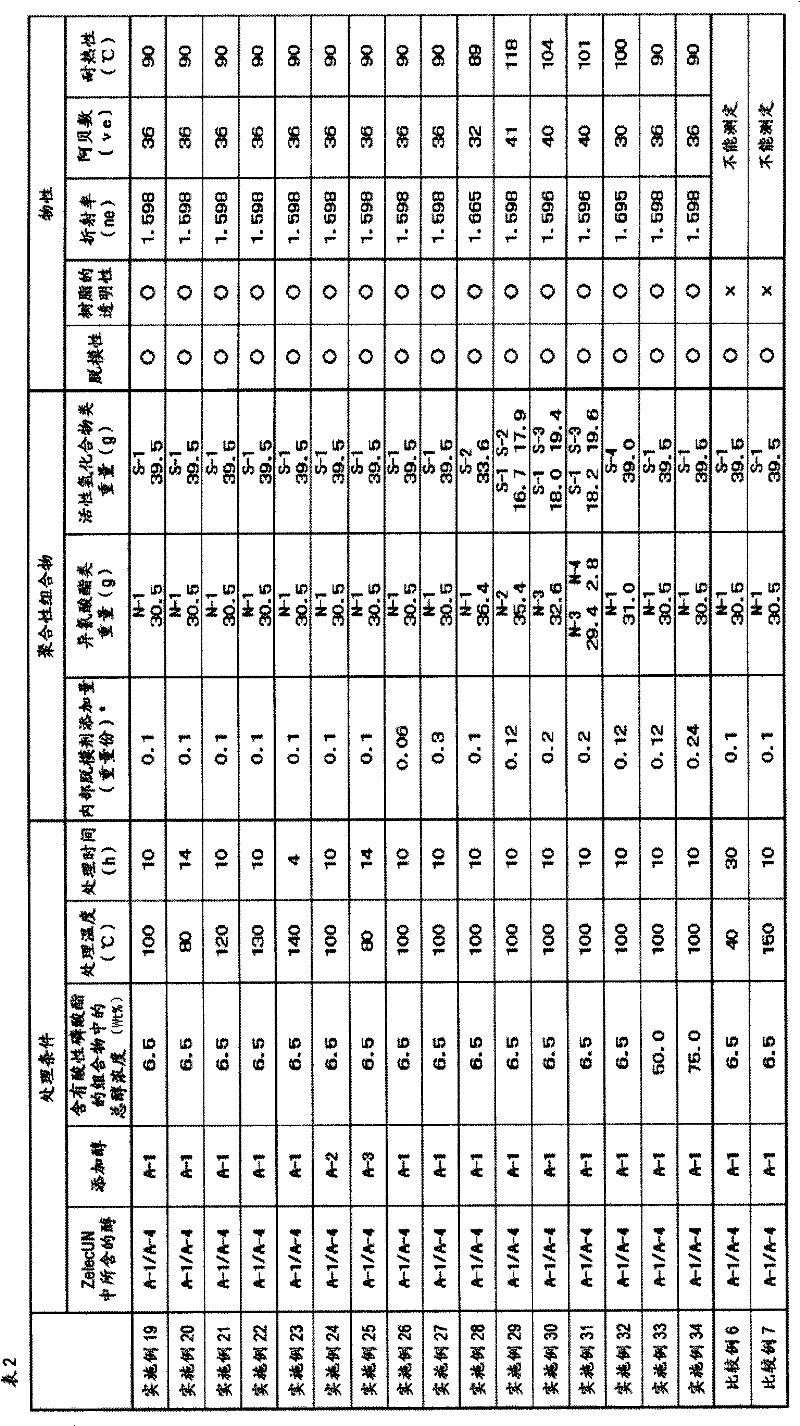

Embodiment 1

[0142] In a reaction flask equipped with a stirring bar, a thermometer, and a Dimroth condenser (Dimroth condenser), the phosphoric acid ester compound, namely ZelecUN (the total alcohol concentration of 1-octanol and 1-decanol: 2.3% by weight) of STEPAN Company's trade name 200 g and 4.0 g of 1-octanol were uniformly mixed to obtain a phosphoric acid ester compound-containing composition having a total alcohol concentration of 4.2% by weight. The temperature was gradually raised from room temperature, and the inner temperature was kept at 100° C. while stirring uniformly for 10 hours. After the stirring was completed, the internal temperature was cooled to room temperature, and then, it was discharged from the reaction flask to obtain 202 g of an internal mold release agent for optical materials.

[0143] 30.5 g of m-xylylene diisocyanate, 39.5 g of pentaerythritol tetrakis(3-mercaptopropionate), and 0.0056 g of di-n-butyltin dichloride (80 ppm relative to the total weight of...

Embodiment 2

[0145] In a reaction flask equipped with a stirring bar, a thermometer, and a Dimroth condenser, 200 g of a phosphoric acid ester compound, the trade name ZelecUN (the total alcohol concentration of 1-octanol and 1-decanol: 2.3% by weight) and 1- 0.6 g of octanol was uniformly mixed to obtain a phosphoric acid ester compound-containing composition having a total alcohol concentration of 2.6% by weight. The temperature was gradually raised from room temperature, and the inner temperature was kept at 100° C. while stirring uniformly for 18 hours. After completion of the stirring, the internal temperature was cooled to room temperature, and then discharged from the reaction flask to obtain 199 g of an internal mold release agent for optical materials.

[0146] 30.5 g of m-xylylene diisocyanate, 39.5 g of pentaerythritol tetrakis(3-mercaptopropionate), and 0.0056 g of di-n-butyltin dichloride (80 ppm relative to the total weight of the polymerizable composition) at 20°C , UV abso...

Embodiment 3

[0148] In a reaction flask equipped with a stirring bar, a thermometer, and a Dimroth condenser, 200 g of a phosphoric acid ester compound, the trade name ZelecUN (the total alcohol concentration of 1-octanol and 1-decanol: 2.3% by weight) and 1- 2.0 g of octanol was uniformly mixed to obtain a phosphoric acid ester compound-containing composition having a total alcohol concentration of 3.3% by weight. The temperature was gradually raised from room temperature, and the inner temperature was kept at 100° C. while stirring uniformly for 10 hours. After completion of the stirring, the internal temperature was cooled to room temperature, and then discharged from the reaction flask to obtain 199 g of an internal mold release agent for optical materials.

[0149]30.5 g of m-xylylene diisocyanate, 39.5 g of pentaerythritol tetrakis(3-mercaptopropionate), and 0.0056 g of di-n-butyltin dichloride (80 ppm relative to the total weight of the polymerizable composition) at 20°C , UV absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com