Resin composition

A resin composition and resin technology, applied in the field of resin composition, can solve the problems of opacity and inability to be used for transparency, etc., and achieve the effect of improving heat resistance and suppressing white turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0121] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated more concretely, this invention is not limited to these examples. In the examples, parts, %, and ppm indicating the usage amount or content are based on weight unless otherwise specified. In addition, methods for measuring and evaluating various physical properties of the obtained resin composition and molded article are as follows.

[0122]

[0123] A resin composition prepared by mixing a methacrylic resin and an aromatic polycarbonate resin is dried at 90°C for 12 hours, and then pressed using a press molding machine ["SHINDO Type ASF Type Hydraulic Press" manufactured by Shindo Metal Industry Co., Ltd.] Press forming was performed at a press temperature of 220° C. to obtain a shaped sheet having a thickness of 3 mm. Then, the obtained formed pieces were press-formed again using the same press-forming machine at press temperatures of 260°C, 270°C, 280°C, and 290...

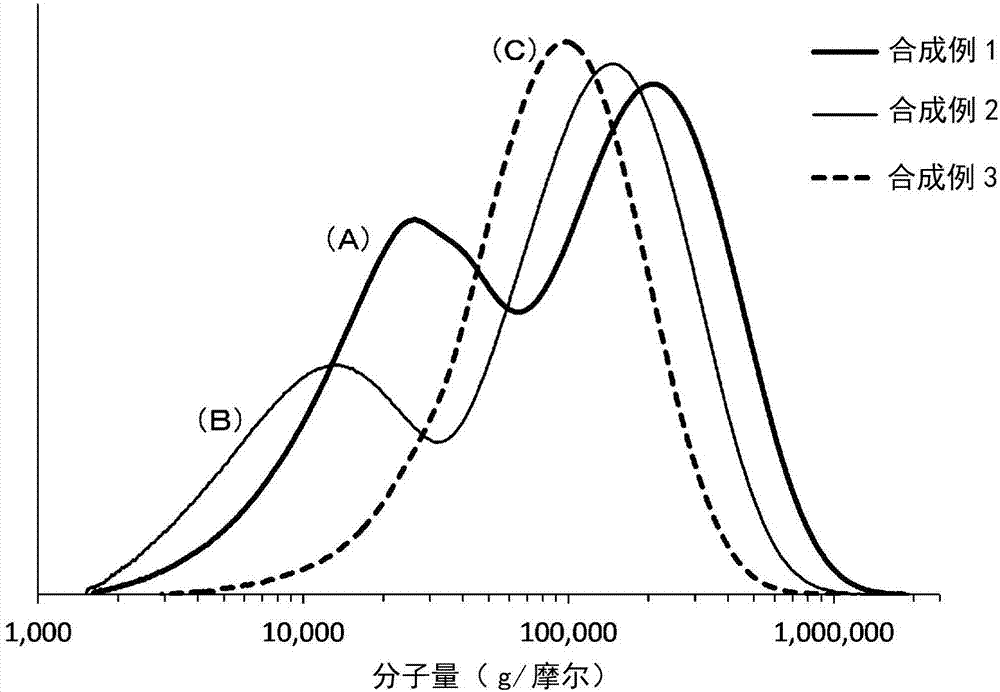

Synthetic example 1

[0132] [Synthesis example 1]: Manufacture of methacrylic resin

[0133] To the first polymerization reactor equipped with a stirrer, 99.5% of methyl methacrylate, 0.5% of methyl acrylate, 0.01 part of t-amyl peroxide 2-ethylhexanoate as a polymerization initiator, and 0.01 part of t-amyl peroxide as a chain 0.10 parts of n-octyl mercaptan as a transfer agent, 0.1 parts of stearyl alcohol as a release agent, and 2-tert-octyl alcohol in an amount equivalent to about 30 ppm of the total amount of the finally obtained methacrylic resin as a heat stabilizer Dialkyl disulfides were polymerized at 140°C with an average residence time of 60 minutes. Then, the reaction solution as a partial copolymer flowing out from the first polymerization reactor is sent to the second polymerization reactor equipped with a stirrer, and an additional injection containing 99.5 parts of methyl methacrylate and 0.5 parts of methyl acrylate as a polymerization initiator 0.01 part of 1,1-di(t-butylperoxy...

Synthetic example 2

[0134] [Synthesis example 2]: Manufacture of methacrylic resin

[0135] To the first polymerization reactor equipped with a stirrer, 99.1% of methyl methacrylate, 0.9% of methyl acrylate, 0.02 parts of t-amyl peroxide 2-ethylhexanoate as a polymerization initiator, and 0.02 parts of tert-amyl peroxide as a chain 0.13 parts of n-octyl mercaptan as a transfer agent, 0.1 parts of stearyl alcohol as a release agent, and di-tert-octyl alcohol in an amount equivalent to about 30 ppm of the total amount of the finally obtained methacrylic resin as a thermal stabilizer. Dialkyl disulfides were polymerized at 140°C with an average residence time of 37 minutes. Then, the reaction liquid as a partial copolymer flowing out from the first polymerization reactor is sent to the second polymerization reactor equipped with a stirrer, and an additional injection containing 99.1% of methyl methacrylate and 0.9% of methyl acrylate as a polymerization initiator 0.01 part of 1,1-di(tert-butylperox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com