Resin composition and molded article thereof

A resin composition, resin-like technology, applied in other household appliances, applications, instruments, etc., can solve the problem of opacity of the resin composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

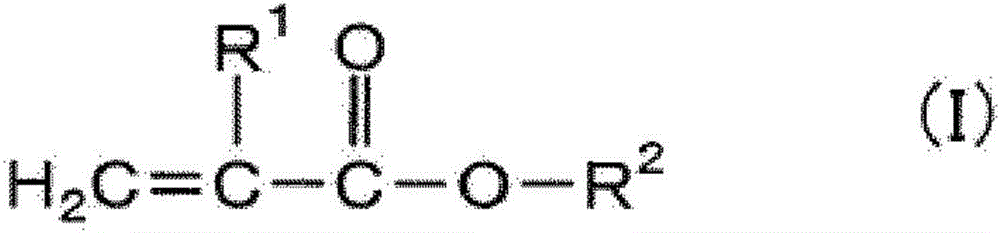

Method used

Image

Examples

Embodiment

[0152] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated concretely, this invention is not limited to these Examples.

[0153] In addition, various physical properties of the obtained resin composition and molded article were measured and evaluated by the following method.

[0154]

[0155] After drying the resin composition at 90°C for 12 hours, press molding at a pressing temperature of 220°C using a press molding machine ("SHINDO Type ASF Type Hydraulic Press" manufactured by Shindo Metal Industry Co., Ltd.) to obtain a thickness Formed sheet of 3mm. Next, the obtained molded pieces were press-molded at respective press temperatures of 270° C., 275° C., 280° C., 285° C., and 290° C. to obtain test pieces each having a thickness of 2 mm and a square of 40 mm. The appearance of each of the obtained test pieces was visually evaluated, and the highest pressing temperature was defined as the cloud point of the resin compos...

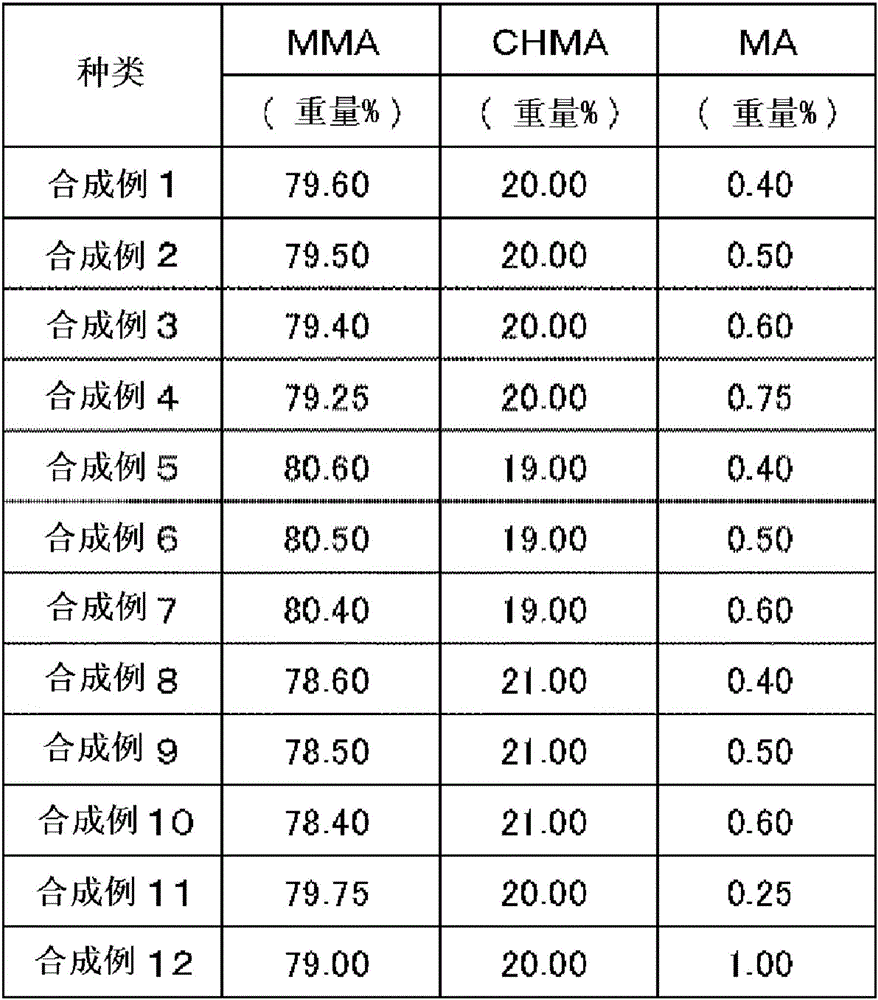

Synthetic example 1~12

[0158] (Synthesis examples 1 to 12: Synthesis of methacrylic resin)

[0159] Methyl methacrylate (MMA), cyclohexyl methacrylate (CHMA), and methyl acrylate (MA) were mixed according to the compositions shown in Table 1 to obtain monomer components. To this monomer component was added 0.2 parts by weight of lauroyl peroxide as a polymerization initiator relative to the sum of the monomer components, and 0.41 parts by weight of 1-decanoyl peroxide as a chain transfer agent relative to the total of the monomer components. Dialkylthiols to dissolve them. On the other hand, 0.05 parts by weight of sodium polyacrylate, 0.24 parts by weight of anhydrous sodium dihydrogen phosphate, and 0.28 parts by weight of disodium hydrogen phosphate heptahydrate were dissolved in 100 parts by weight of ion-exchanged water to form a suspension polymerization Aqueous phase Furthermore, 150 weight part of aqueous phases were added to 100 weight part of said monomer components, and suspension polyme...

Synthetic example 13~14

[0162] (Synthesis Examples 13-14: Synthesis of Methacrylic Resin)

[0163] CHMA was changed to phenyl methacrylate (PhMA), the amount of 1-dodecylmercaptan added was set to 0.30 parts by weight relative to the total monomer components, and MMA was set as shown in Table 2 , the composition of PhMA and MA, it carried out similarly to synthesis examples 1-12, and obtained the bead-shaped methacrylic resin.

[0164] [Table 2]

[0165]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| molar absorption coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com