Filler for solar cell module, solar cell module using same, and method for producing filler for solar cell module

A technology for solar cell components and filling materials, which is applied to electrical components, circuits, photovoltaic power generation, etc., can solve the problems of no filling material statement, and the prevention of white turbidity of filling materials has not been proposed, and achieve the effect of suppressing white turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

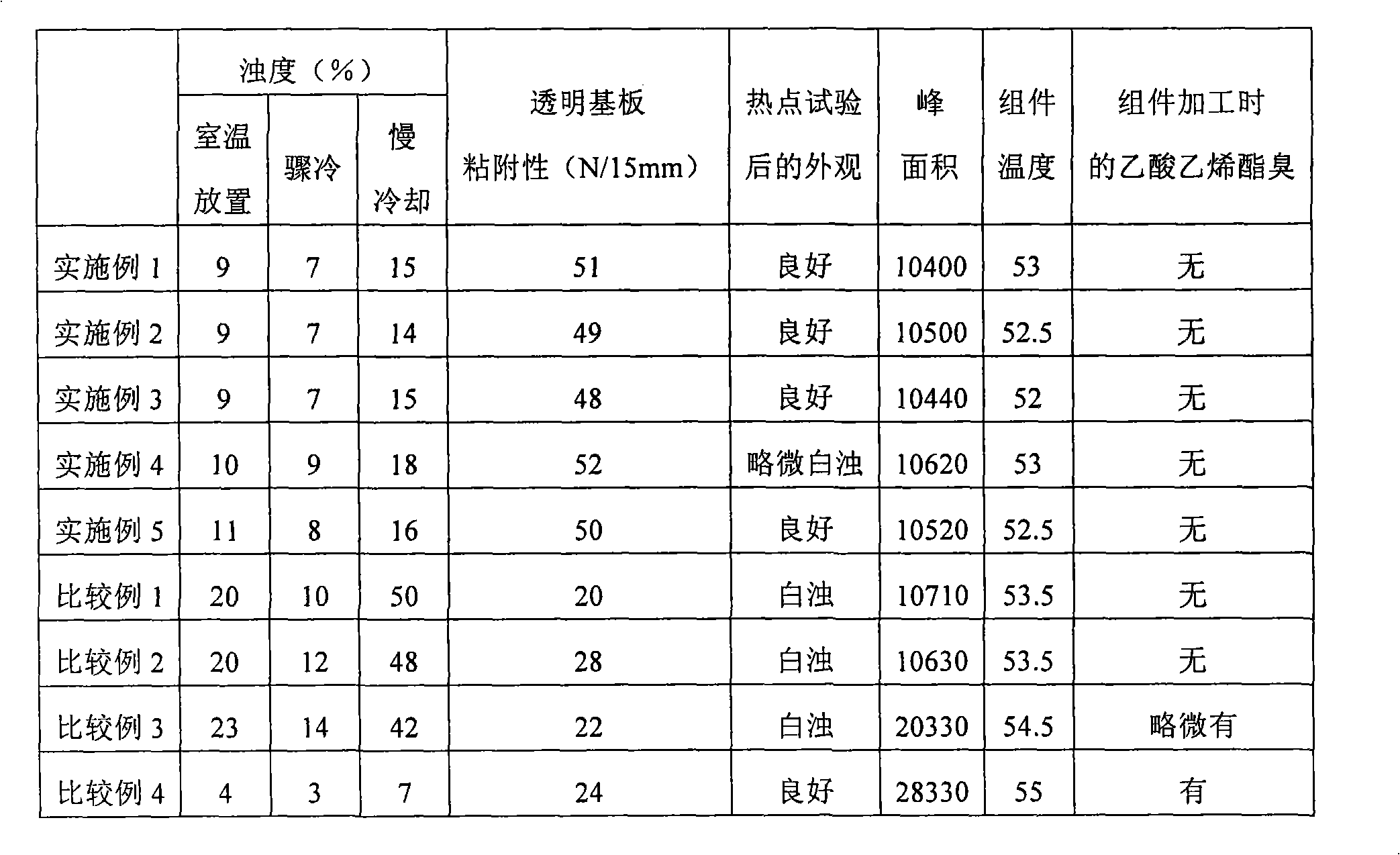

Examples

Embodiment 1

[0130] (Preparation of silane modified resin)

[0131] For a density of 0.898g / cm 3 In 100 parts by weight of metallocene linear low-density polyethylene, 2.5 parts by weight of vinyltrimethoxysilane and 0.1 part by weight of dicumyl peroxide as a free radical generator (reaction catalyst) were mixed at 200° C. Melt and knead to obtain silane-modified resin.

[0132] (Preparation of master compound)

[0133] For crushing density 0.900g / cm 3 In 100 parts by weight of powder made of metallocene linear low-density polyethylene, 3.75 parts by weight of benzotriazole-based ultraviolet absorbers, 5 parts by weight of hindered amine-based light stabilizers, and 0.5 parts by weight of phosphorus-based heat stabilizers were mixed. parts by weight, melted and processed to obtain pelletized parent rubber.

[0134] (Production of filler materials for solar cell modules)

[0135] For 20 parts by weight of the silane-modified resin, mix 5 parts by weight of the master compound, and pol...

Embodiment 2

[0139] (Preparation of master compound)

[0140] For a density of 0.898g / cm 3 In 30 parts by weight of powder obtained by pulverizing metallocene linear low-density polyethylene, the mixing density is 0.900g / cm 3 70 parts by weight of metallocene linear low-density polyethylene, 7 parts by weight of benzotriazole-based ultraviolet absorber, 10 parts by weight of hindered amine-based light stabilizer, and 1 part by weight of phosphorus-based heat stabilizer, are melted , processing to obtain pelletized parent rubber.

[0141] (Production of filler materials for solar cell modules)

[0142] For 40 parts by weight of the silane-modified resin used in Example 1, mix 5 parts by weight of the master compound, and polyethylene as an additive with a density of 0.900 g / cm 3 60 parts by weight of metallocene linear low-density polyethylene, using the same method as in Example 1, to produce a solar cell module filler.

[0143] Furthermore, a solar cell module was fabricated by the sa...

Embodiment 3

[0145] (Preparation of master compound)

[0146] For a density of 0.896g / cm3 In 100 parts by weight of powder obtained by pulverizing metallocene linear low-density polyethylene, 3.75 parts by weight of a benzotriazole-based ultraviolet absorber, 2.5 parts by weight of a hindered amine-based light stabilizer, and a phosphorus-based thermal stabilizer 0.25 parts by weight of the agent, melted and processed to obtain pelletized parent rubber.

[0147] (Production of filler materials for solar cell modules)

[0148] For 10 parts by weight of the silane-modified resin used in Example 1, 5 parts by weight of the master compound was mixed, and the density of the polyethylene used as addition was 0.900 g / cm 3 90 parts by weight of metallocene linear low-density polyethylene, using the same method as in Example 1, to produce a solar cell module filler.

[0149] Furthermore, a solar cell module was fabricated by the same method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com