Towline leacher grid plate cleaning system

A cleaning system and extractor technology, which is applied to chemical instruments and methods, mobile filter element filters, fat oil/fat production, etc., can solve the problem that the gaps of the towline extractor grids are easy to be blocked, and achieve good circulation and gaps The effect of maintaining smooth flow and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

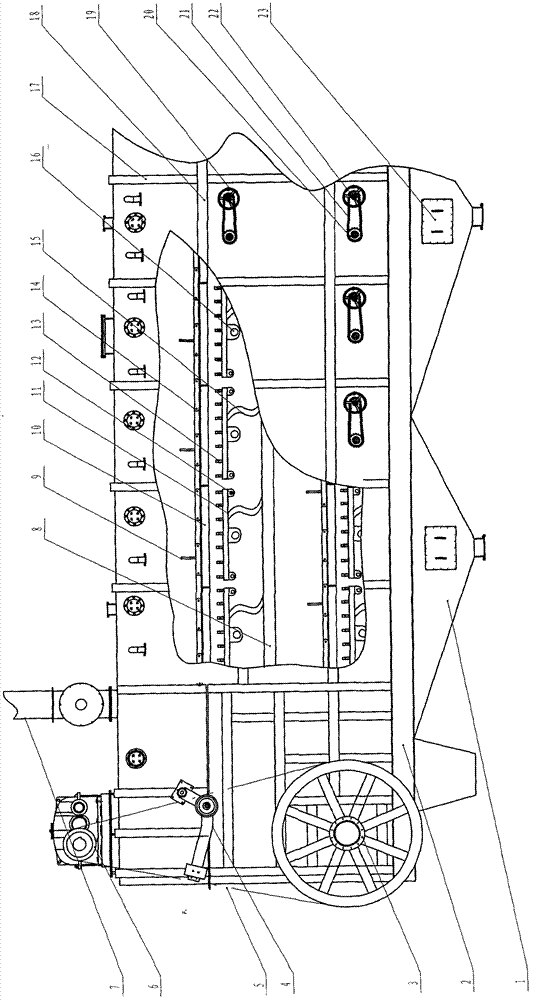

[0013] The products involved in this project are as follows: figure 1 As shown in the drag chain extractor grid plate cleaning system, an oil bucket 1 is provided under the frame 2; The frame 2 is provided with a driving wheel and a driven wheel through a conveying chain 14 for transmission. The driving wheel is provided with a driving wheel 3; through the driving wheel and the tensioner 4 provided on the reducer 6, the driving wheel 3 is driven to make the conveying chain 14 run; the conveying scraper 9 provided on the conveying chain 14 is used to drive the oil Run to complete the oil extraction process in the oil. A two-layer assembled movable grid 10 is arranged in the frame 2 for supporting the conveying chain 14, the conveying scraper 9 and the oil; the lower part of the movable grid 10 is provided with a grid cleaning device. Below each movable grid plate 10 is provided with a shower head connecting pipe 11, the nozzle connecting pipes 11 are arranged in a longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com