Internal high-pressure forming device and forming process

A technology of internal high pressure forming and internal high pressure, which is applied in the field of internal high pressure forming, can solve the problems of unsuitable thin-walled pipe fittings, etc., achieve the effect of reducing the demand for internal pressure, ensuring smooth completion, and reducing the requirements for feeding and forming elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

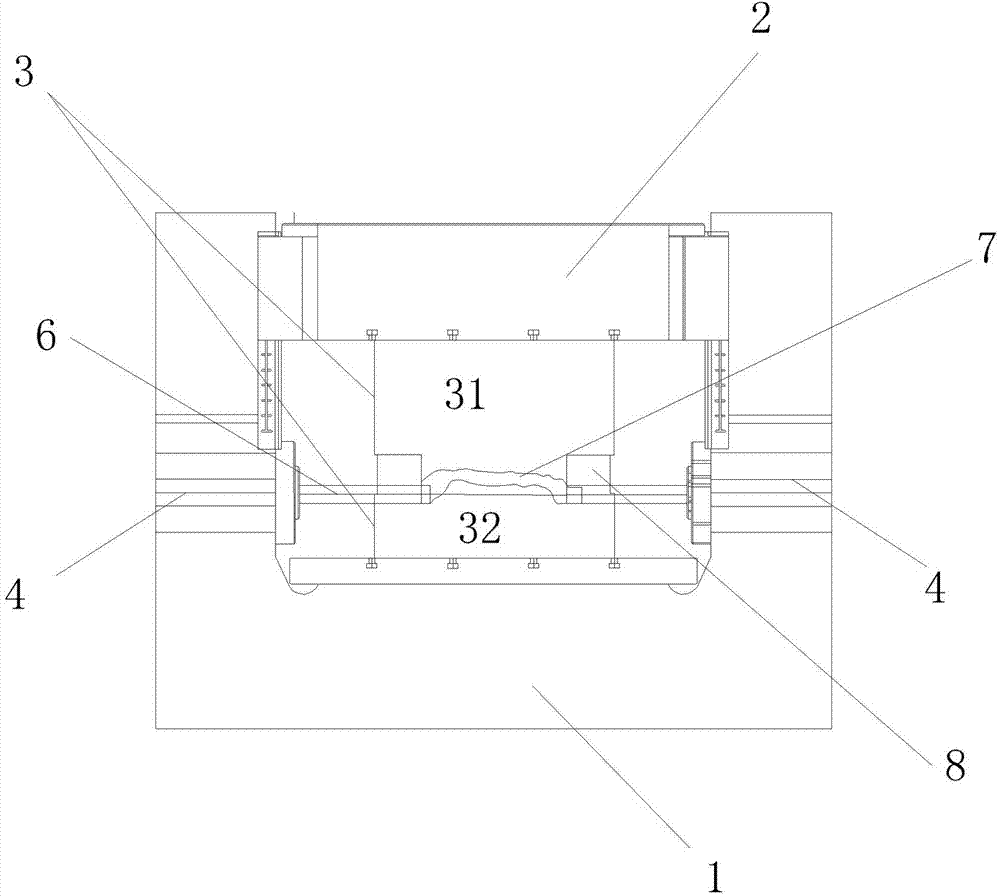

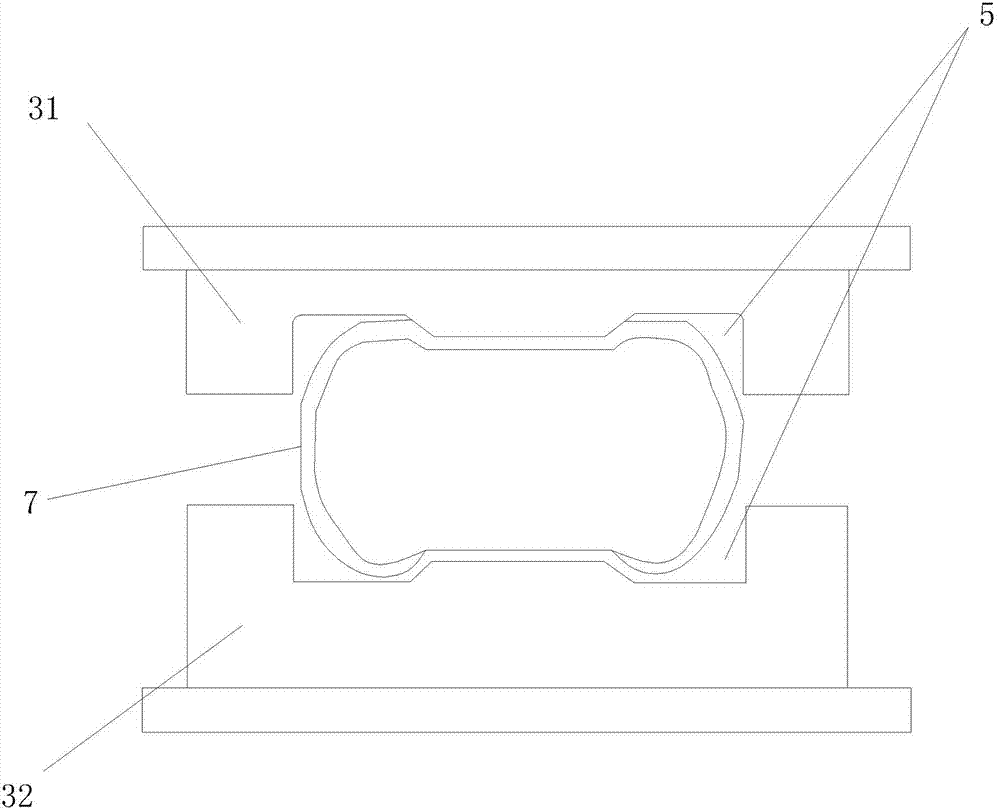

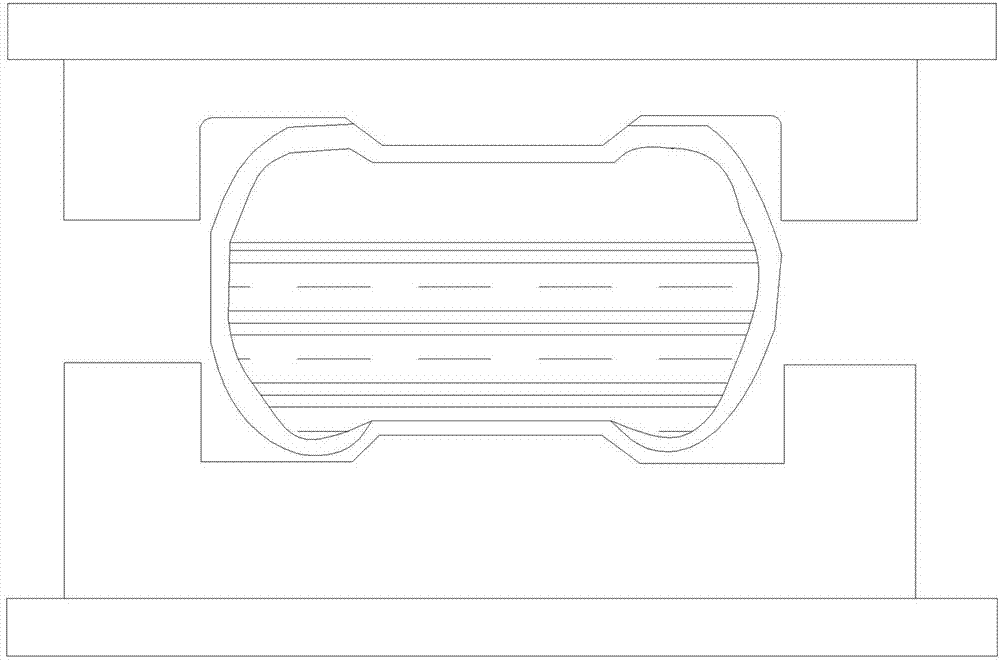

[0024] Such as figure 1 As shown, this embodiment is a kind of internal high pressure forming equipment, including a frame 1, which is equipped with a clamping press 2, a booster pump connected to an external water tank (not shown in the figure), an internal high pressure mold 3 and a plurality of feeding cylinders 4 for feeding. The internal high-pressure mold 3 includes an upper mold 31 and a lower mold 32, a horizontal worktable is formed on the frame, the lower mold is fixedly placed on the horizontal platform, and the upper mold is connected to the bottom of the press And it can press and close the mold with the press. Cavities are respectively opened in the upper mold and the lower mold. When the upper mold and the lower mold are closed, the cavity of the upper mold and the lower mold can form a mold cavity 5 consistent with the outli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com