Container and steel floor chassis thereof

A technology for steel floors and containers, applied in the field of containers, can solve the problems of high cost and low manufacturing efficiency, and achieve the effects of reducing self-weight, reducing labor costs, and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

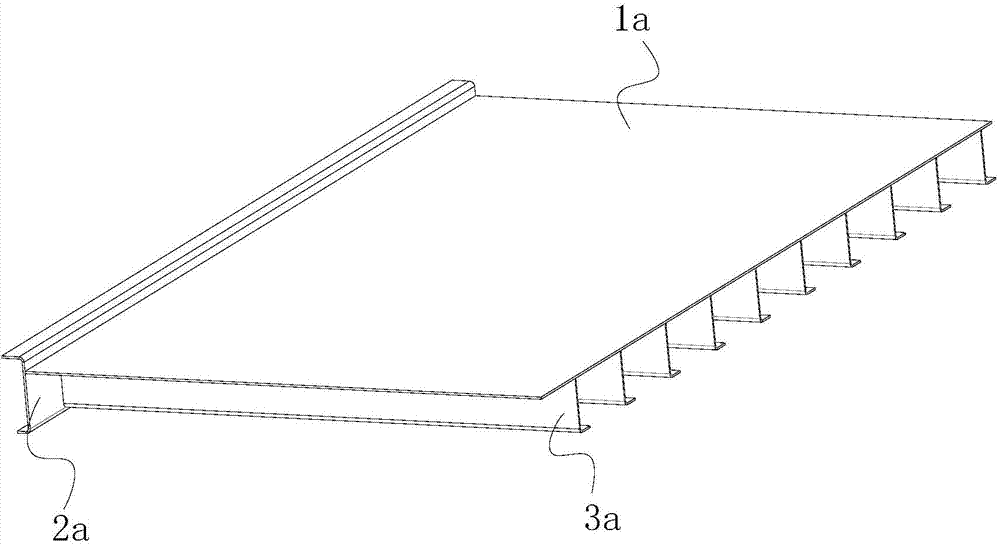

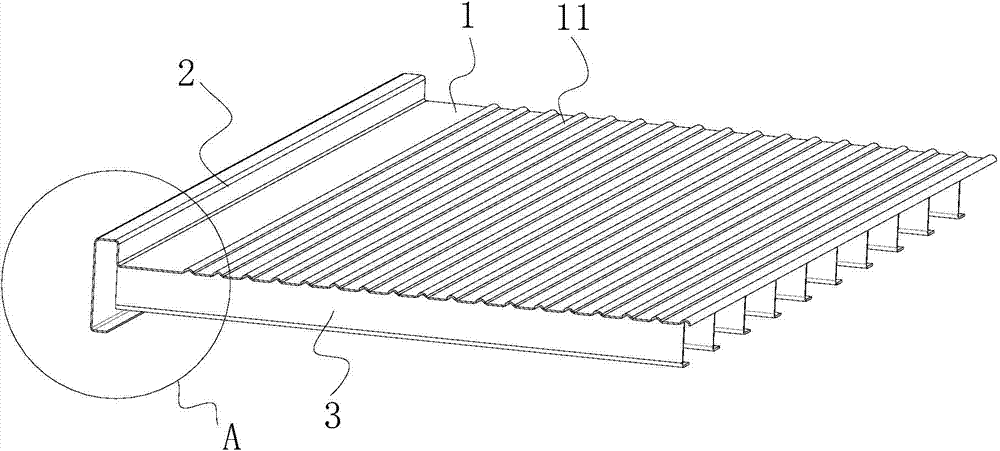

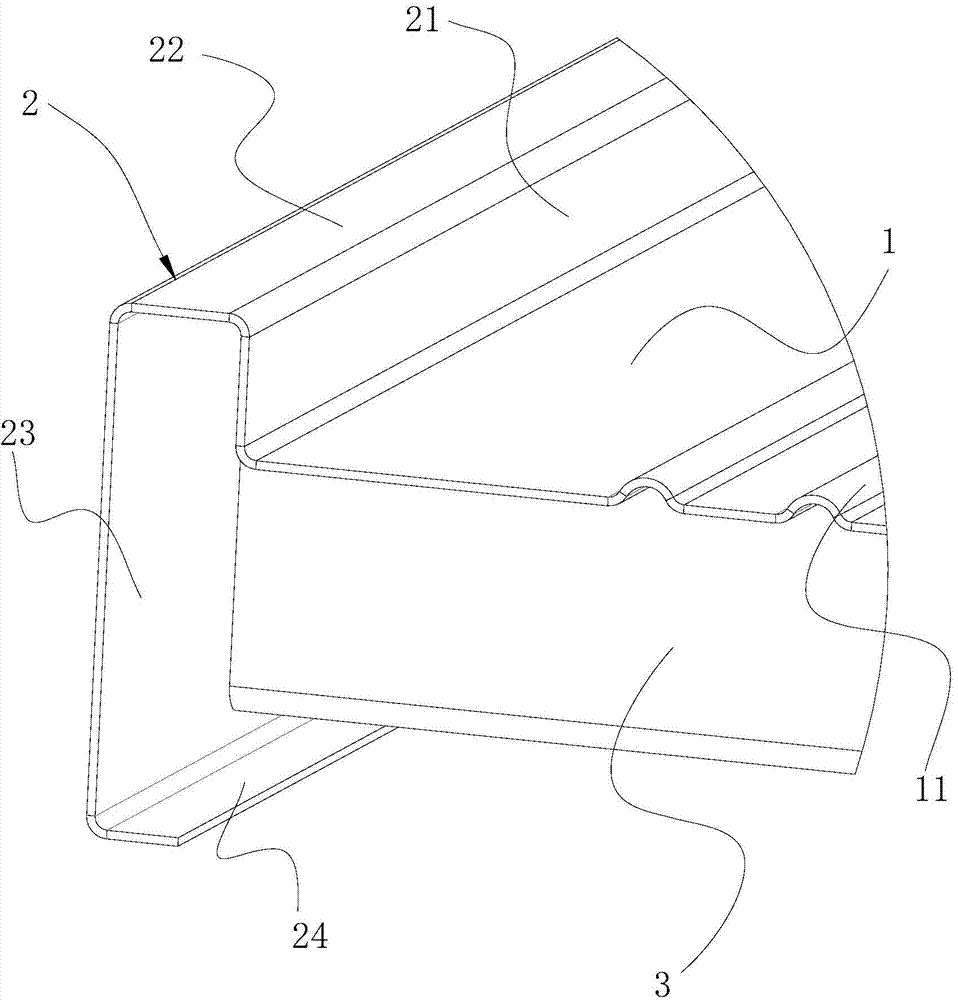

[0023] see figure 2 and image 3 , this embodiment provides a container steel floor chassis, including a steel floor 1, bottom side beams 2 and bottom cross beams 3, the bottom side beams 2 are located on both sides of the steel floor 1 in the transverse direction, and the bottom side beams 2 extend from the sides of the steel floor 1 The edge is bent and integrally formed with the steel floor 1 (only one side of the steel floor is shown in the figure), the bottom beam 3 is located below the steel floor 1, and there are multiple longitudinally spaced ones. The upper end of the bottom beam 3 is connected to the The lower surface of the steel floor 1 is welded and fixed, and the two ends of the bottom beam 3 are respectively welded and fixed with the two bottom side beams 2 . The steel floor 1 is provided with strip-shaped reinforcing ribs 11 protruding upwards in the longitudinal direction, and multiple reinforcing ribs 11 are distributed in the transverse direction of the st...

no. 2 example

[0028] see Figure 4 and Figure 5 , in this embodiment, the difference from the first embodiment is that the bottom side beam 2 is L-shaped, and the bottom side beam 2 includes a web 26 bent vertically downward from the side of the steel floor 1 and a web 26 from the lower end of the web 26 The wing plate 27 bent vertically inward, the end of the bottom beam 3 and the inner side of the web 26 are welded and fixed. In this embodiment, the structure of the bottom and side beams is relatively simple, and other structures of the steel floor chassis in this embodiment are the same as those in the first embodiment, and will not be repeated here.

[0029] When the steel floor chassis of this embodiment is assembled into a container, the side edges of the steel floor 1 are used to weld and fix with the side panels of the container. Similarly, the welding can also be performed from the outside of the box to avoid welding seams inside the box.

[0030] In the above two embodiments, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com