Electroconductive Particles

A conductive particle, conductive technology, applied in the direction of oxide conductors, non-metallic conductors, conductive materials dispersed in non-conductive inorganic materials, etc., to achieve the effect of high environmental resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

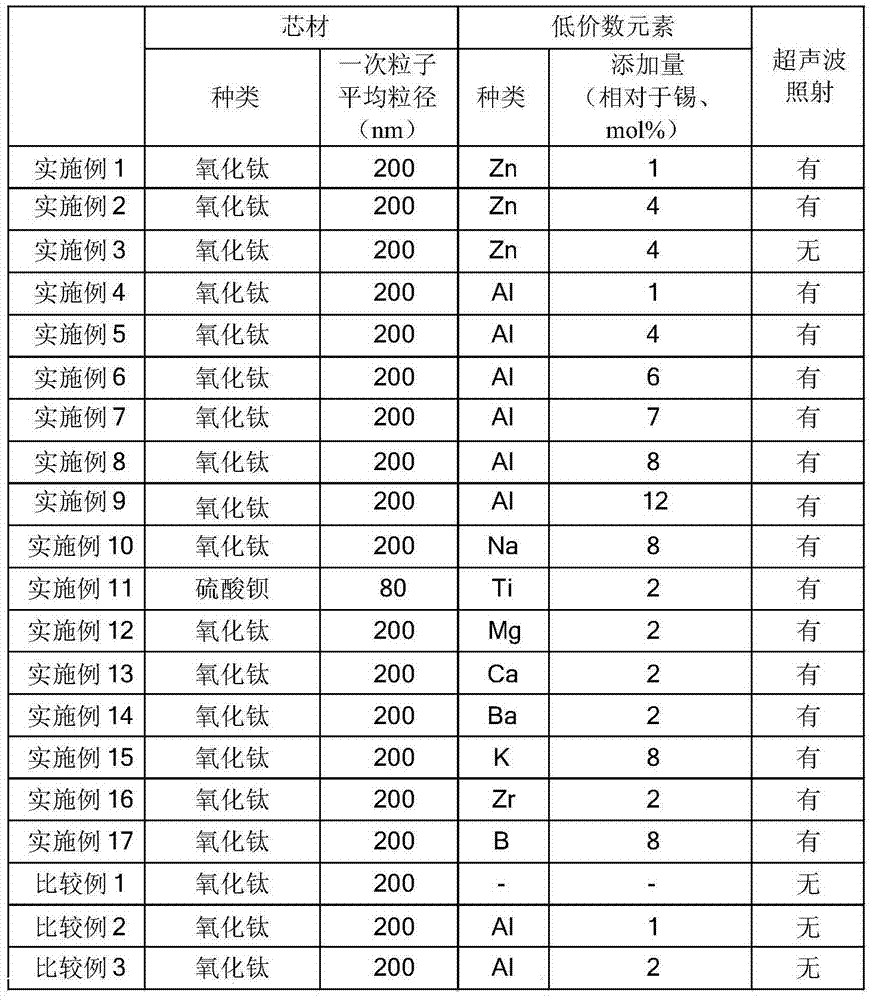

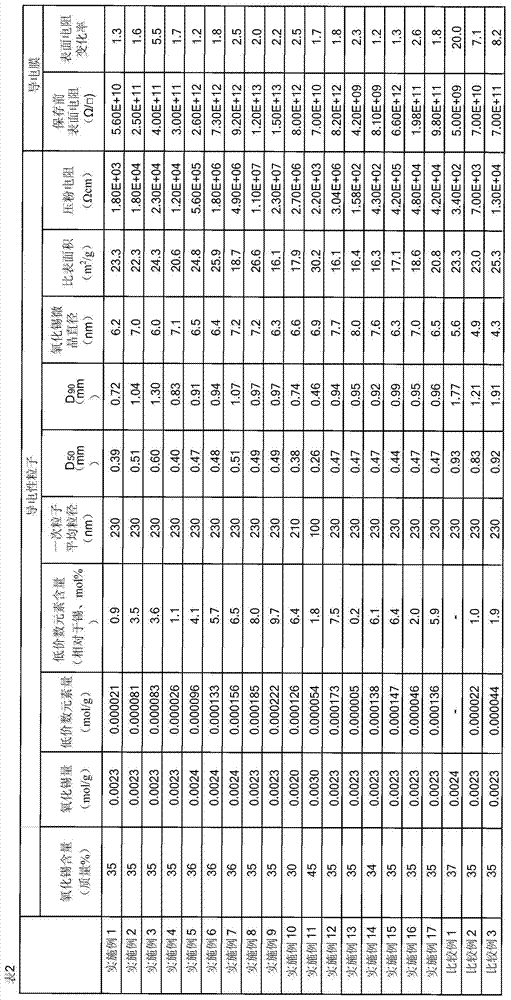

Embodiment 1

[0068] A slurry was obtained by dispersing 200 g of titanium oxide particles (average particle diameter of primary particles: 200 nm) as a core material in 3 L of water. In this slurry, adding tin content is 41% sodium stannate (Na 2 SnO 3 ) 208g and make it dissolve, obtain mixed slurry. While circulating the mixed slurry, ultrasonic waves were irradiated by an ultrasonic oscillator installed in a part of the circulation path. The frequency of the ultrasound is set to 40kHz, and the output power is set to 570W. While irradiating ultrasonic waves to the circulating mixed slurry, a 20% dilute sulfuric acid aqueous solution was added to the mixed slurry to neutralize tin. Dilute aqueous sulfuric acid was added over 60 minutes until the pH of the mixed slurry reached 2.5. After neutralization, 0.97 g of zinc(II) chloride (grade 98%) was added to the mixed slurry, and the mixed slurry was stirred. Thereby, the precursor of the target electroconductive particle is obtained. A...

Embodiment 2

[0070] The amount of zinc chloride used in Example 1 was set as shown in Table 1. Except for this, electroconductive particle was obtained similarly to Example 1.

Embodiment 3

[0072] In Example 2, irradiation of ultrasonic waves was not performed. Except for this, electroconductive particle was obtained similarly to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com