Longitudinal and transverse combination sleeper

A technology of combining sleepers and sleepers, which is applied in the directions of tracks, roads, ballast layers, etc., can solve the problems of high cost and difficult maintenance, and achieve the effect of simple structure and preventing sliding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

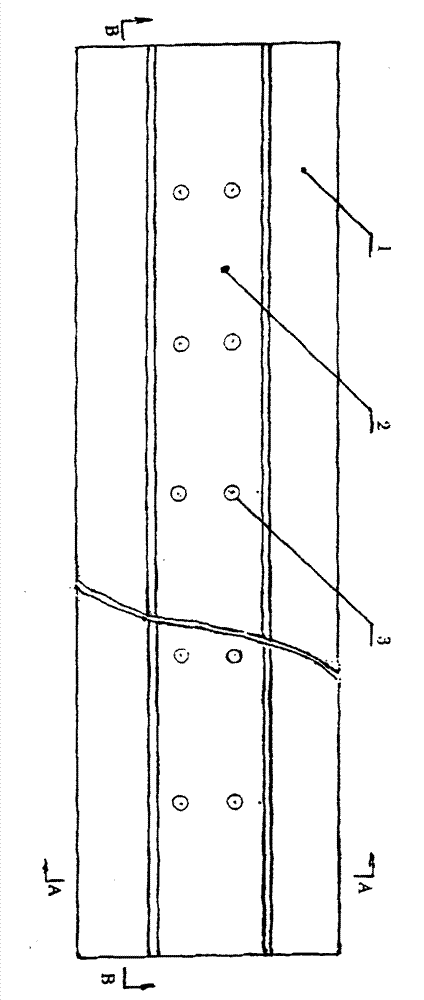

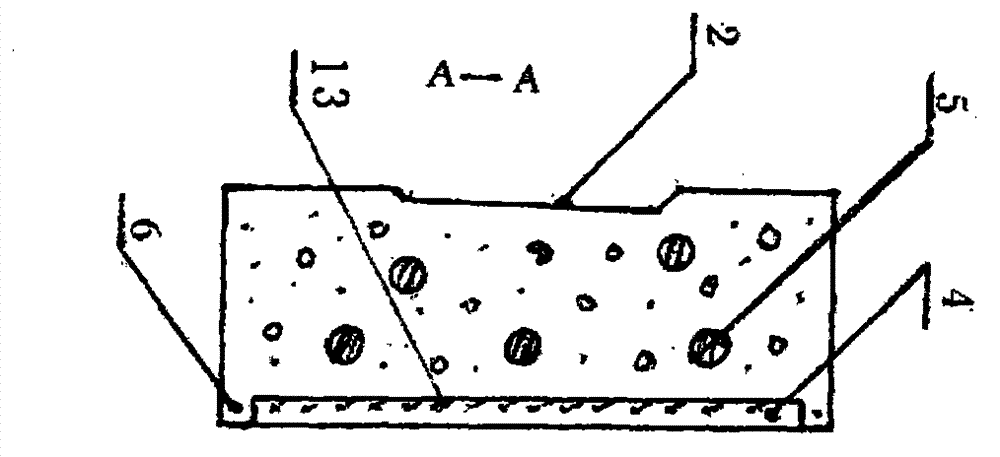

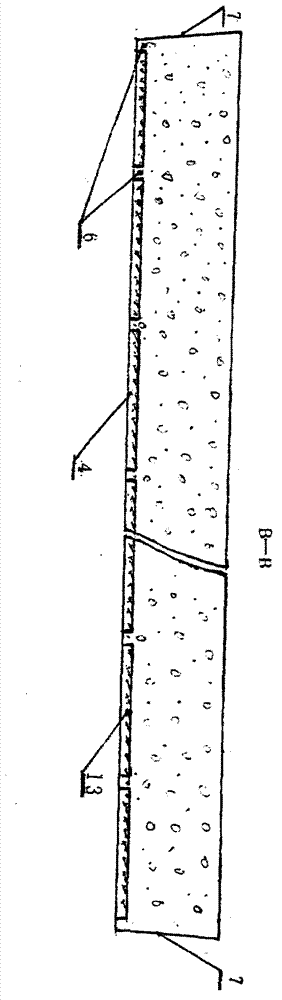

[0017] The vertical and horizontal sleeper is a new technical solution for the rail support method implemented by new products: the rail is supported by the combination of the type III sleeper and the longitudinal sleeper, such as Figure 4 As shown, a shaped III type sleeper 8 is laid horizontally between two steel rails 9, and then a longitudinal sleeper 1 is laid respectively under the two steel rails along the direction of the steel rails, and then a vertical sleeper 1 is laid between the two steel rails. Lay a type III transverse sleeper 8, and fix the longitudinal sleeper and the transverse sleeper on the rail with fasteners 11, for simplicity, Figure 4 Only one horizontal sleeper and one fastener on the longitudinal sleeper are drawn in the figure. The distance between the fasteners on the longitudinal sleeper is according to the railway specification. Spike holes are reserved in the longitudinal sleeper, between the bottom surface of the rail and the rail bearing groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com