Valve stem and valve sleeve of a steam turbine control valve

A technology for regulating valves and steam turbines, applied in valve details, valve devices, mechanical equipment, etc., can solve problems such as increasing user maintenance costs, affecting the stability, reliability, safety and economy of steam turbines, and increasing wear resistance. , reduce friction, reduce the effect of steam leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

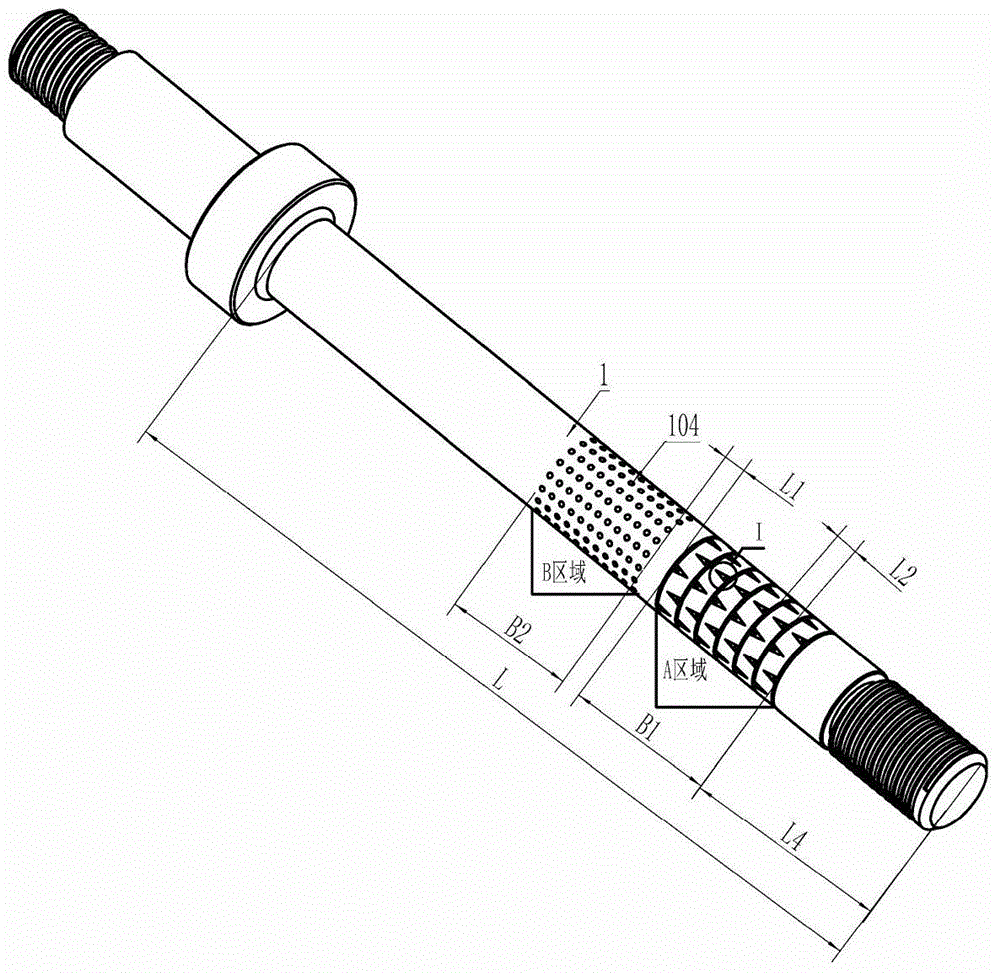

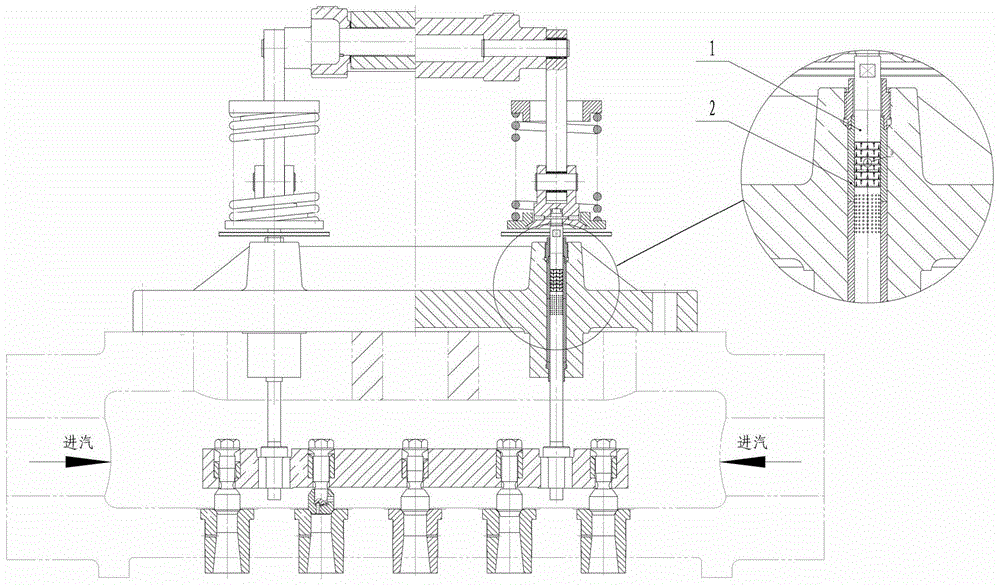

[0033] like figure 1 , figure 2 As shown, the valve stem 1 has A region and B region in the matching region of the valve sleeve 2, and the B region is at the lower end of the A region; the A region is a dynamic pressure balance region, and the B region is a hydrophobic region, wherein the A region Set at the position where the distance L4 from the outlet end of the valve stem accounts for 1 / 8 to 1 / 6 of the total length L of the valve stem; the distance L1 between the A area and the B area is 10-20mm; the width B1 of the A area accounts for the total length of the valve stem 1 / 6~1 / 5 of the total length of the valve stem, and the width B2 of the B area accounts for 1 / 6~1 / 5 of the total length of the valve stem.

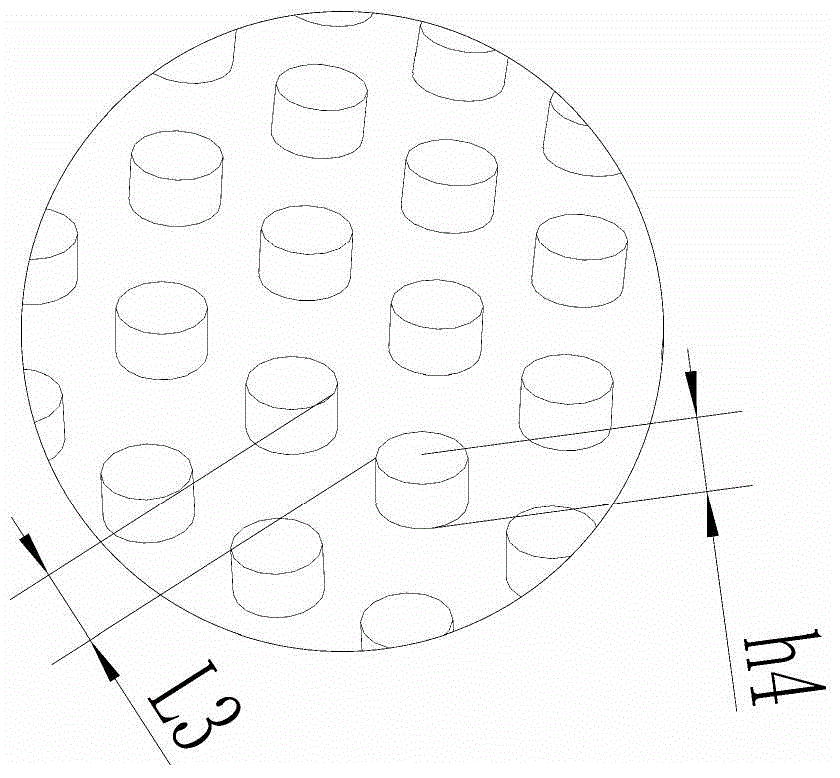

[0034] The area surface of the dynamic pressure balance area is provided with a valve stem seal liquid storage tank 103, and a dynamic pressure balance tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com