A fastening bracket fastening rotary fin heat exchanger

A technology for fixing brackets and heat exchangers, which is applied to heat exchange equipment, heat exchanger shells, evaporators/condensers, etc. Insufficient fixation with the spiral finned tube, low bracket installation efficiency, etc., to achieve the effect of improving input cost and processing efficiency, not easy to loosen, and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

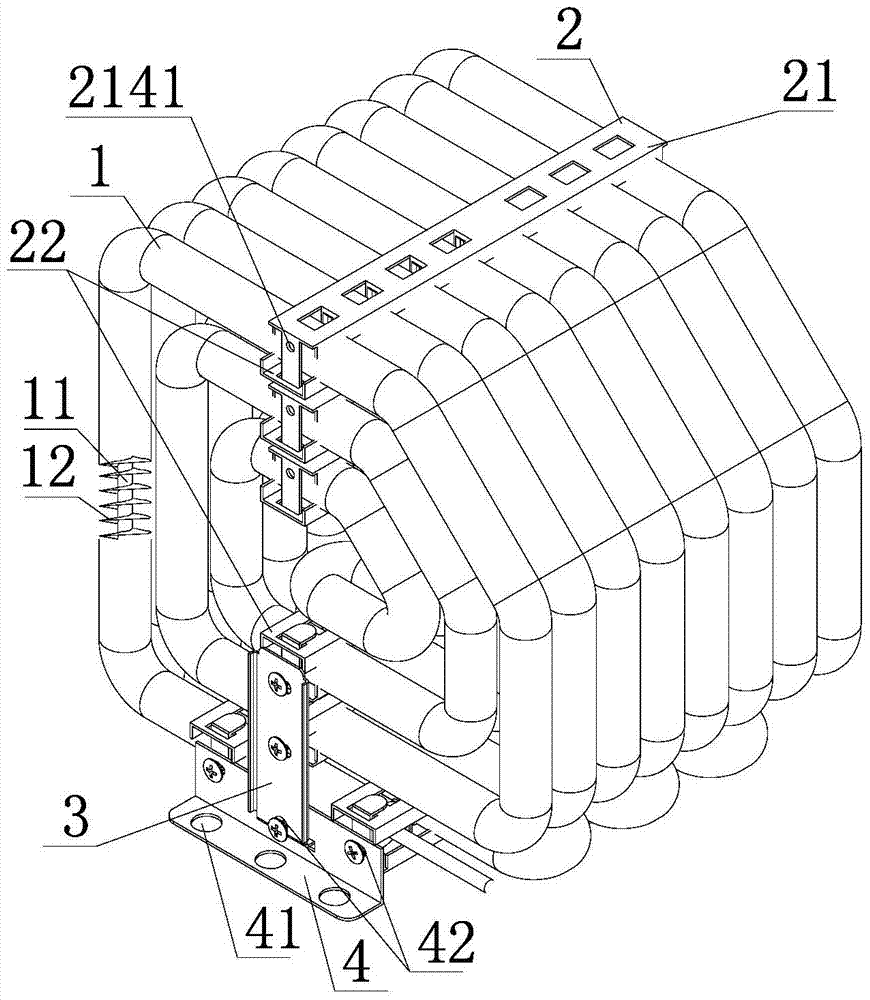

[0020] see Figure 1-Figure 4 As shown, a fastening bracket fastening rotary fin heat exchanger, which includes a spiral finned tube 1 with a coiled layer structure, seven sets of spiral finned tube plane fixing frames 2, a plane fixing frame connecting plate 3 and a bottom fixing plate 4, The spiral-finned tube 1 of the roll layer structure includes a condenser tube 11 and a spiral fin 12 spirally wound outside the condenser tube 11;

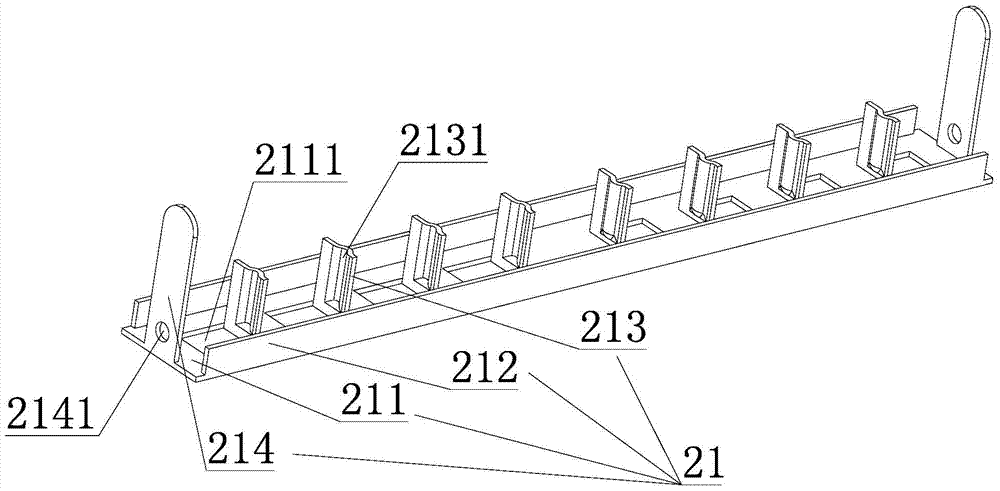

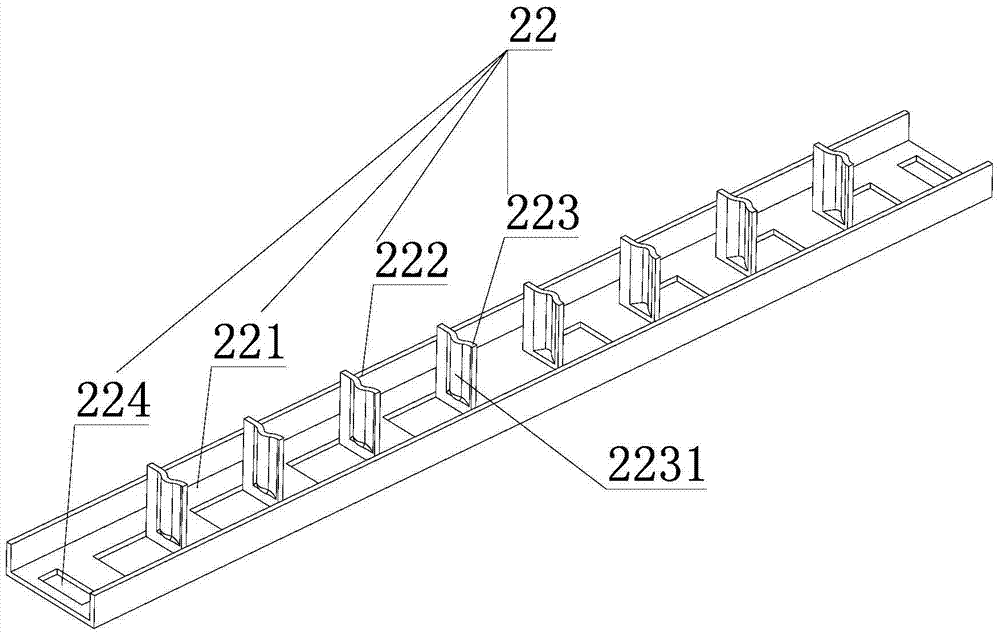

[0021] Said each set of spiral finned tube plane fixtures 2 includes a small bracket 21 and a small bracket cover plate 22; the small bracket 21 and the small bracket cover plate 22 are arranged in a direction perpendicular to the pipeline direction of the spiral finned tube, and the roll layer structure The spiral finned tube whose upper part is in the same plane is sandwiched between a group of small brackets 21 and the small bracket cover plate 22, and the small brackets 21 and the small bracket cover plate 22 are inserted and fixed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com