Calibrating method and device for mass flow controller

A technology of mass flow and calibration method, applied in the direction of using electric device flow control, etc., can solve problems such as large error in MFC calibration results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] In order to make the above objects, features and advantages of the embodiments of the present invention more comprehensible, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

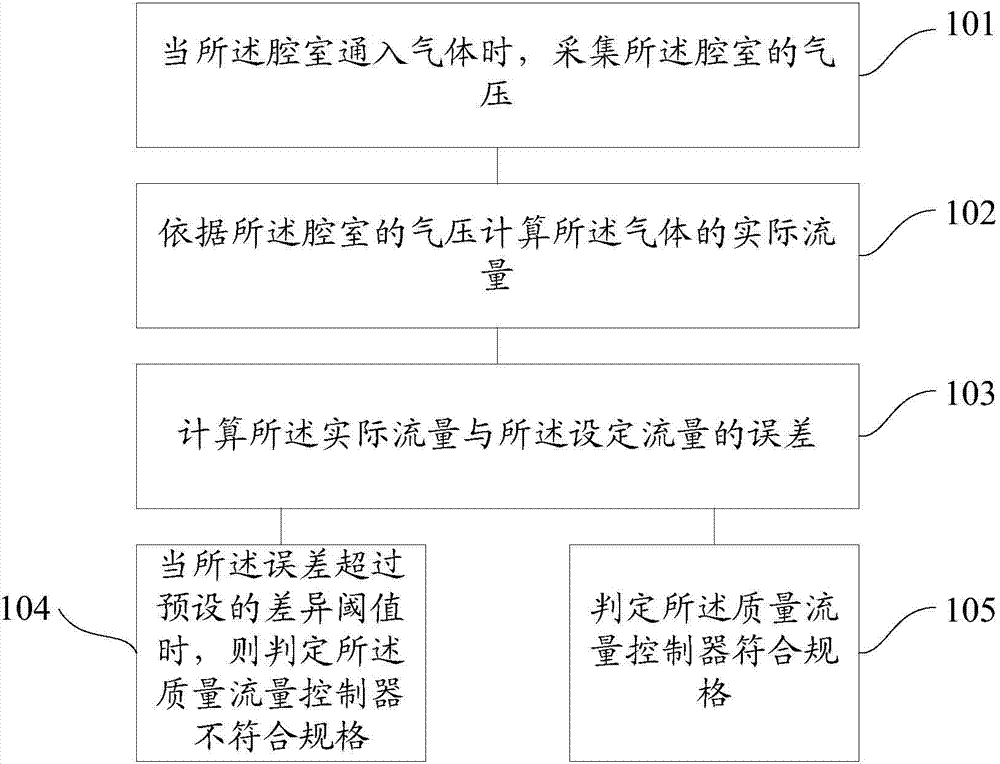

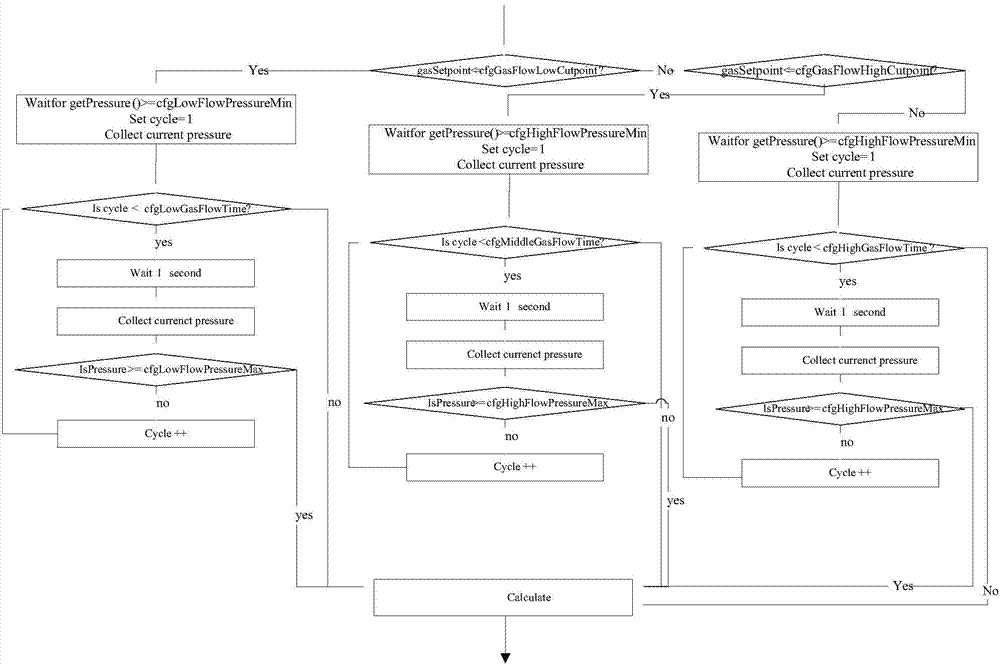

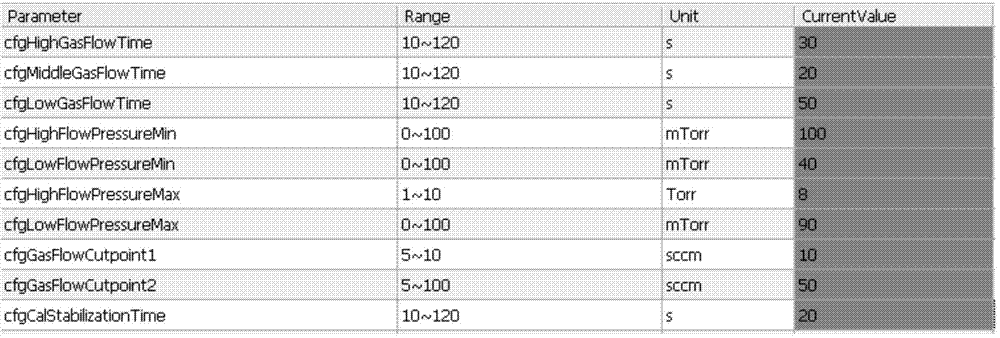

[0086] refer to figure 1 , shows a flow chart of the steps of an embodiment of a method for calibrating a mass flow controller in an embodiment of the present invention, the mass flow controller may be set in a semiconductor device, and the mass flow controller may be set with a The set flow rate of the incoming gas, such as figure 1 As shown, the method may specifically include the following steps:

[0087] Step 101, when the chamber is filled with gas, collect the air pressure of the chamber;

[0088] It should be noted that the semiconductor device can be atmospheric pressure chemical vapor deposition (Atmospheric Pressure Chemical Vapor Deposition, APCVD), chemical vapor depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com