Method of early warning operating condition of equipment

A technology for equipment operation and status, applied in the direction of non-electric variable control, instruments, control/regulation systems, etc., can solve problems such as failure to detect equipment abnormalities in time, and achieve the goal of improving equipment maintenance timeliness, improving efficiency, and increasing service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below, so that those skilled in the art can implement it with reference to the text of the description.

[0034] It should be understood that terms such as "having", "including" and "including" used herein do not equate the presence or addition of one or more other elements or combinations thereof.

[0035] A method for early warning of equipment operating conditions, the equipment refers to instrumentation and electrical equipment, and the method includes the following steps:

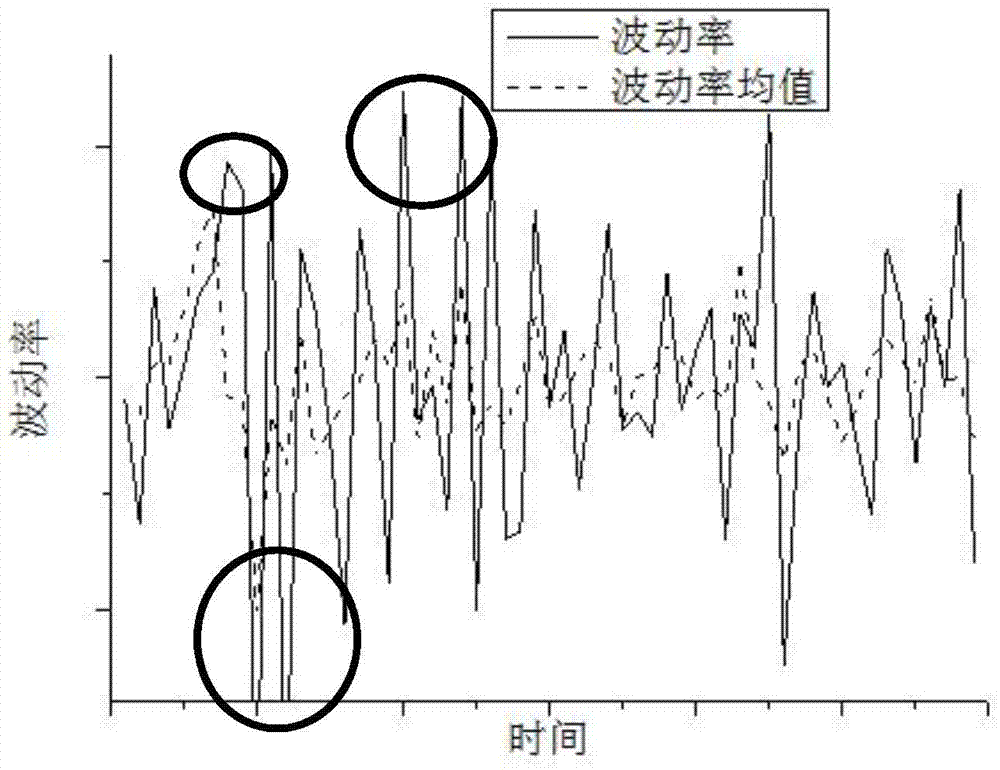

[0036] Step 1. For instruments and meters, directly obtain the detected values and store them in the database. For electrical equipment such as water pumps and fans, the current can be obtained by installing sensors that detect its operating current. Some abnormal data in the monitoring data need to be removed by filtering first to avoid interference with the analysis of volatility.

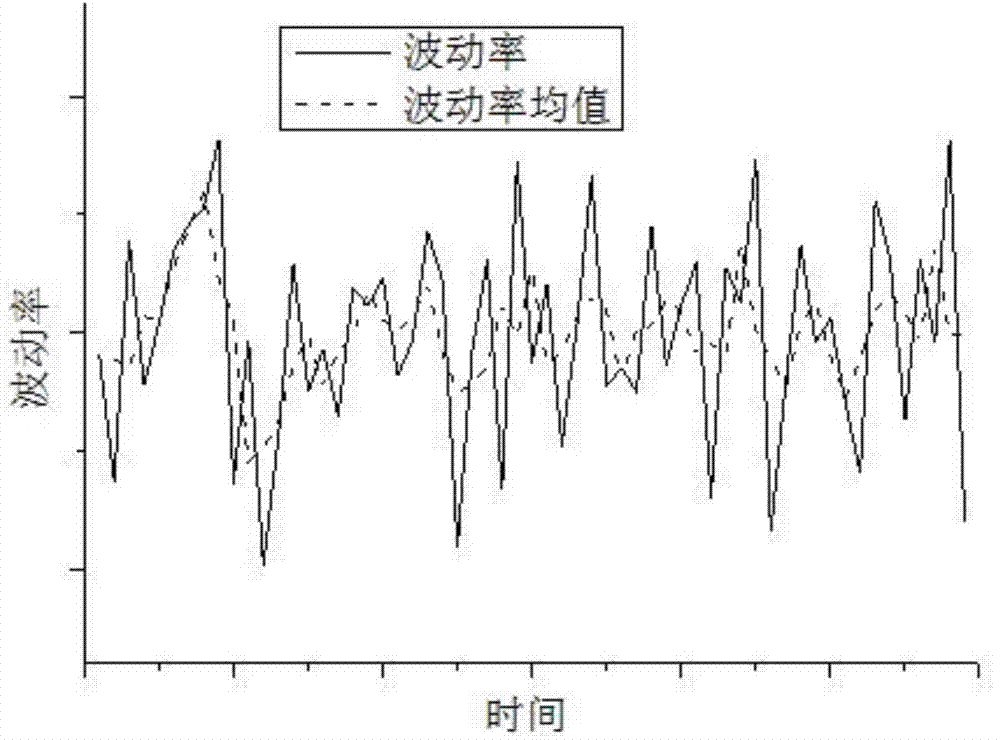

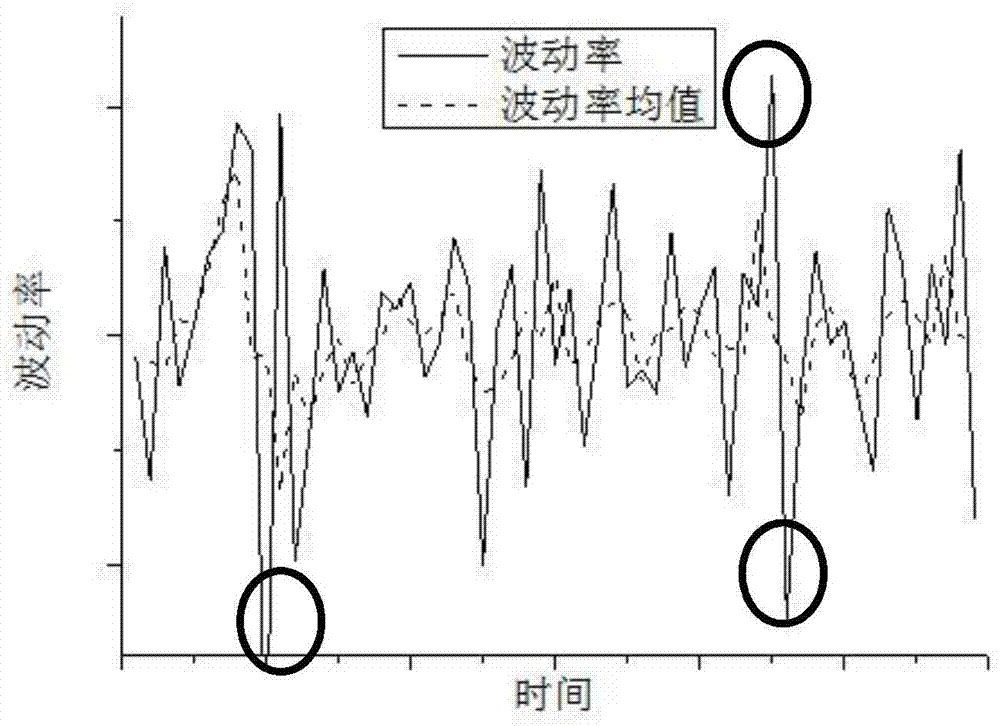

[0037] Step 2: Calculate the volatility k and the average vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com