A power supply control device and a packed cell

A technology for power control devices and battery packs, which is applied in secondary batteries, battery pack components, secondary battery repair/maintenance, etc. It can solve the problems of electric vehicles not being able to drive, avoid charging, improve safety, and prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

[0150] Next, a second embodiment of the present invention will be described with reference to the drawings.

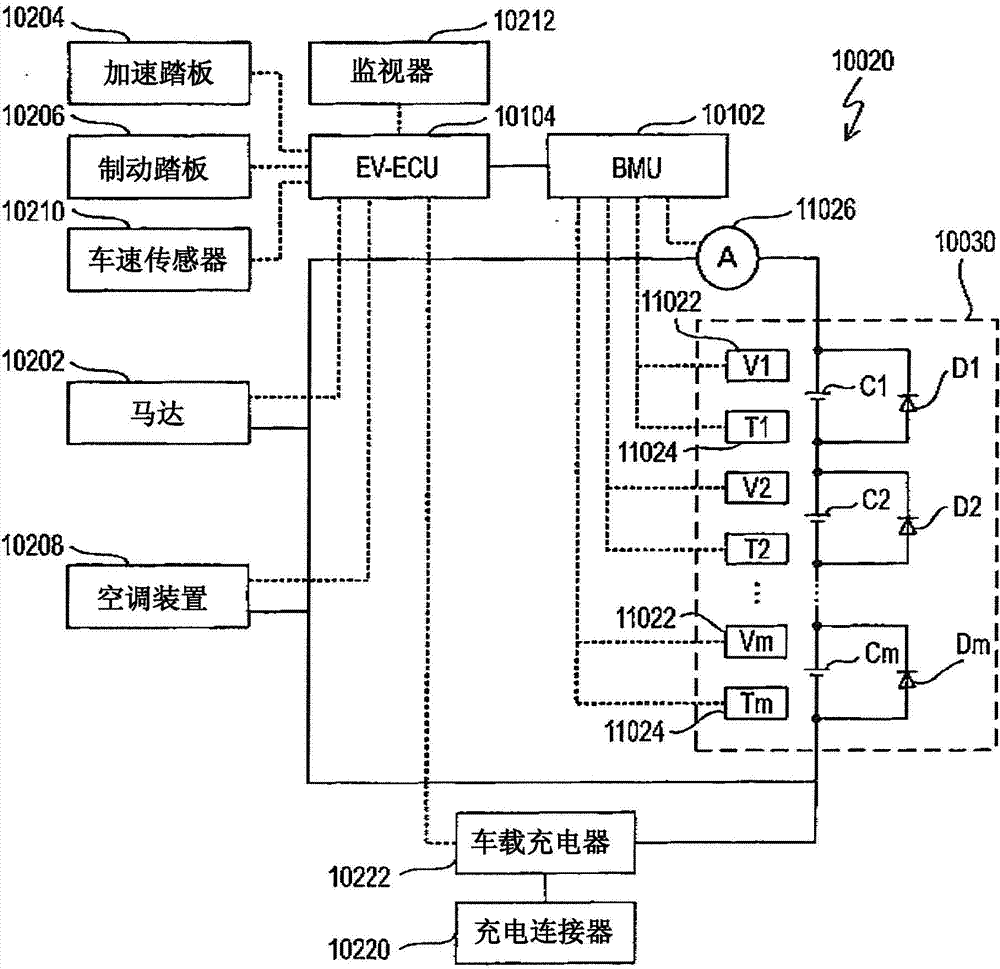

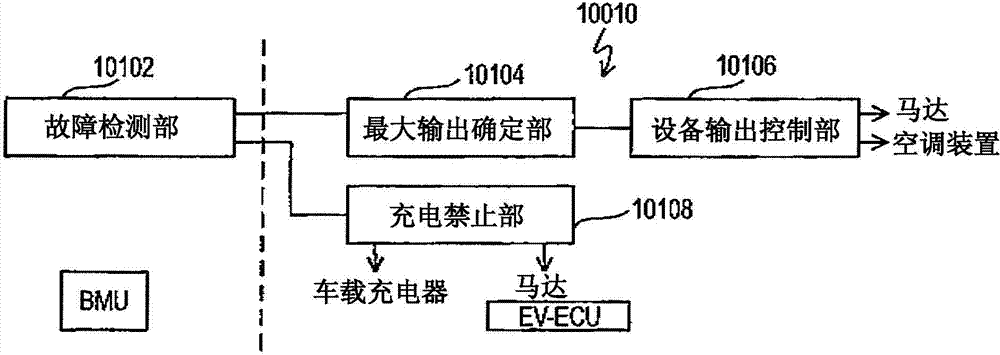

[0151] The assembled battery according to the present embodiment is mounted on an electric vehicle running by driving a motor using electric power, and is used as a running battery for storing electric power for running the electric vehicle.

[0152] First, the electrical configuration of a general battery pack will be described.

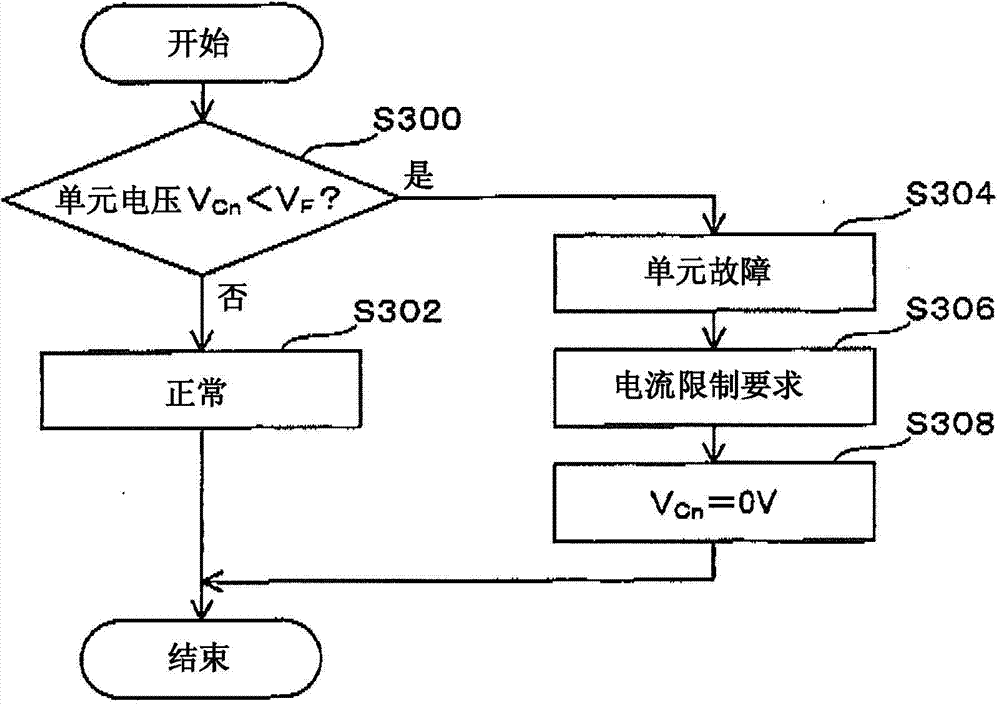

[0153] Such as Figure 8 As shown, the assembled battery 20010 includes a plurality of battery cells 20012 connected in series; and a plurality of rectifying elements 20018 connected in parallel to each of the plurality of battery cells 20012 to supply power to the load R (motor).

[0154] Among the plurality of battery cells 20012, when any battery cell 20012 fails, the current flows through the rectifying element 20018 connected to the battery cell 20012, so that the power supply from the assembled battery 20010 to the load R can be maint...

no. 3 Embodiment approach

[0208] Next, refer to Figure 11 The third embodiment will be described.

[0209] In addition, in the following embodiment, the same code|symbol is attached|subjected to the same part and member as 2nd Embodiment, and description is abbreviate|omitted.

[0210] In the third embodiment, the wiring structure of the rectifying element 20018, the positive terminal 20022A, and the negative terminal 20022B is different from that of the second embodiment, and other points are the same as those of the second embodiment.

[0211] Such as Figure 11 As shown, the rectifier element 20018 has an anode terminal 21804 and a cathode terminal 21806 provided on a main body 21802. The main body 21802 has a heat dissipation plate 21802B for dissipating heat from the main body 21802. The anode terminal 21804 is connected to the negative terminal via the second wiring 20028 (wiring). 20022B is electrically connected, which is the same as the second embodiment.

[0212] In the third embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com