LED constant current driver

A constant current driver and constant current control technology, applied in lighting devices, light sources, electric light sources, etc., can solve the problems of increased loss of regulating tubes and control units, reduced efficiency of constant current drivers, etc., and achieve the effect of low ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

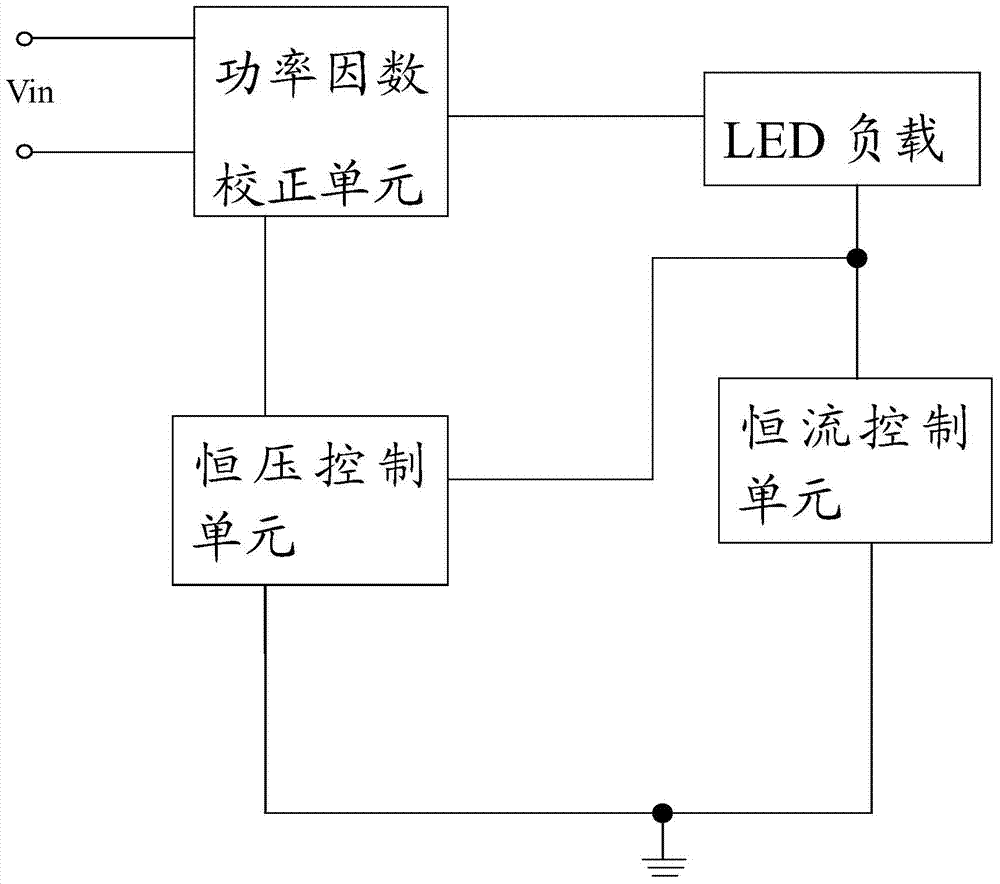

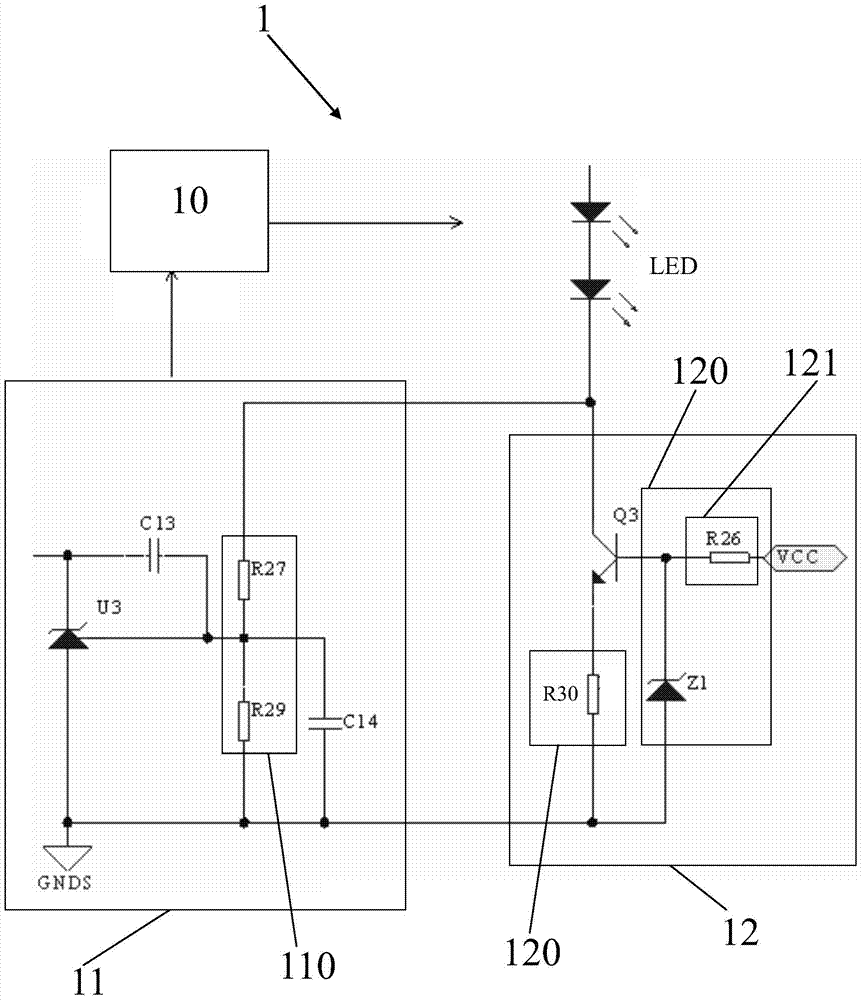

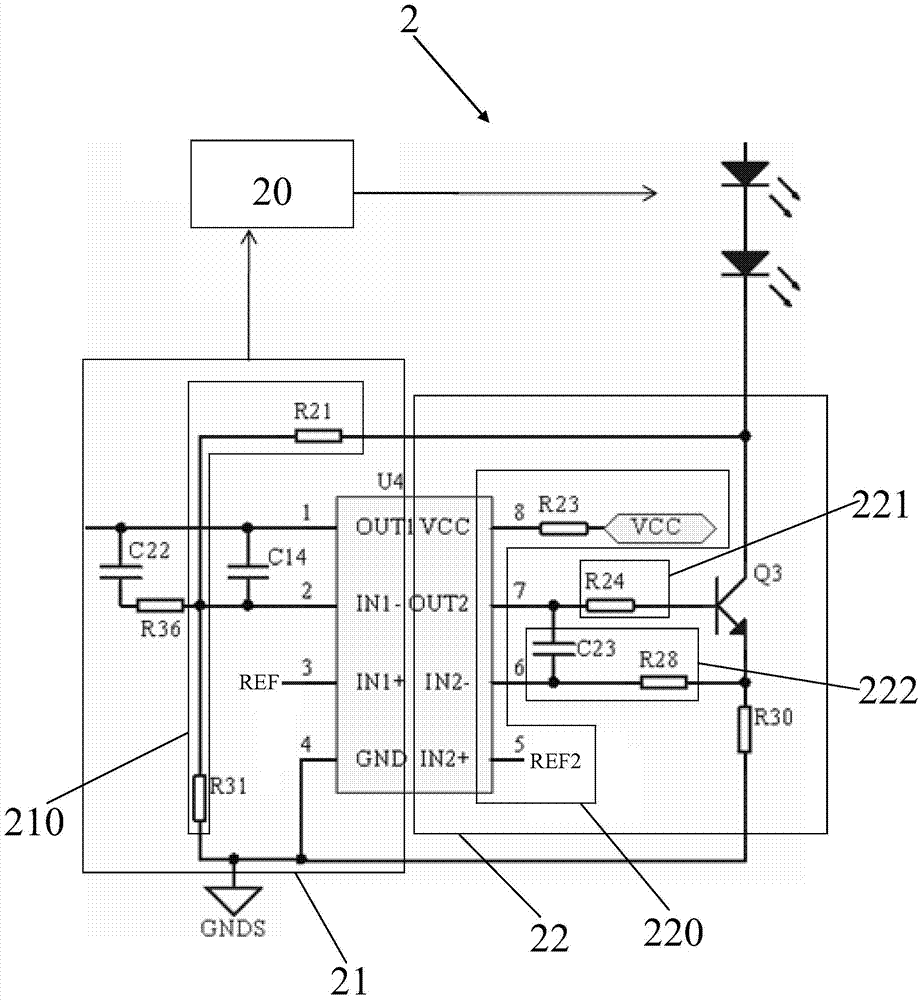

[0018] Please refer to figure 1 As shown, an LED constant current driver of the present invention provides constant current drive for LED loads, and includes a power factor correction unit, a constant voltage control unit and a constant current control unit. The first end of the constant current control unit is connected to the negative end of the LED load, and one end of the constant voltage control unit is connected between the constant current control unit and the negative end of the LED load. The constant current control unit controls the current flowing through the LED load, and the constant voltage control The unit controls the voltage of the first terminal of the constant current control unit. The LED constant current driver of the present invention uses a power factor correction unit to provide voltage for the LED load. On the one hand, it provides a constant current control unit connected to the negative terminal of the LED load to control the constant current flowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com