Sampling device, sampling method, and material management method of molten metal poured into mold

A technology of molten metal and mold pouring, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve problems such as forgetting to sample, poor yield rate, danger, etc., and achieve the effect of improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

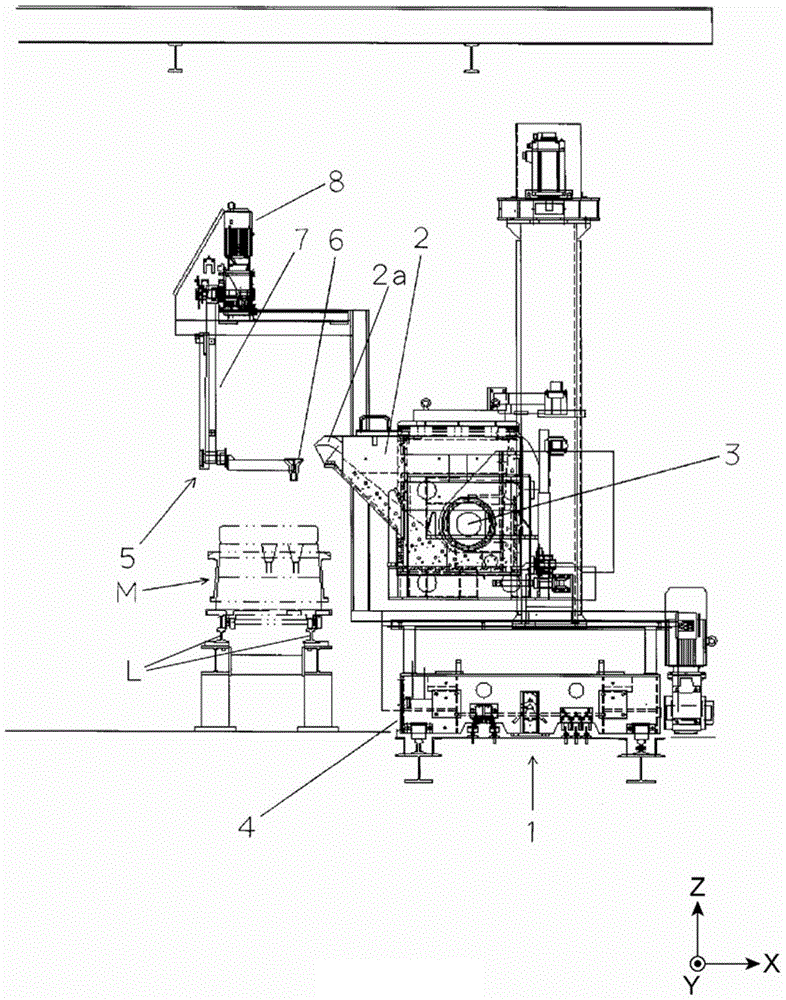

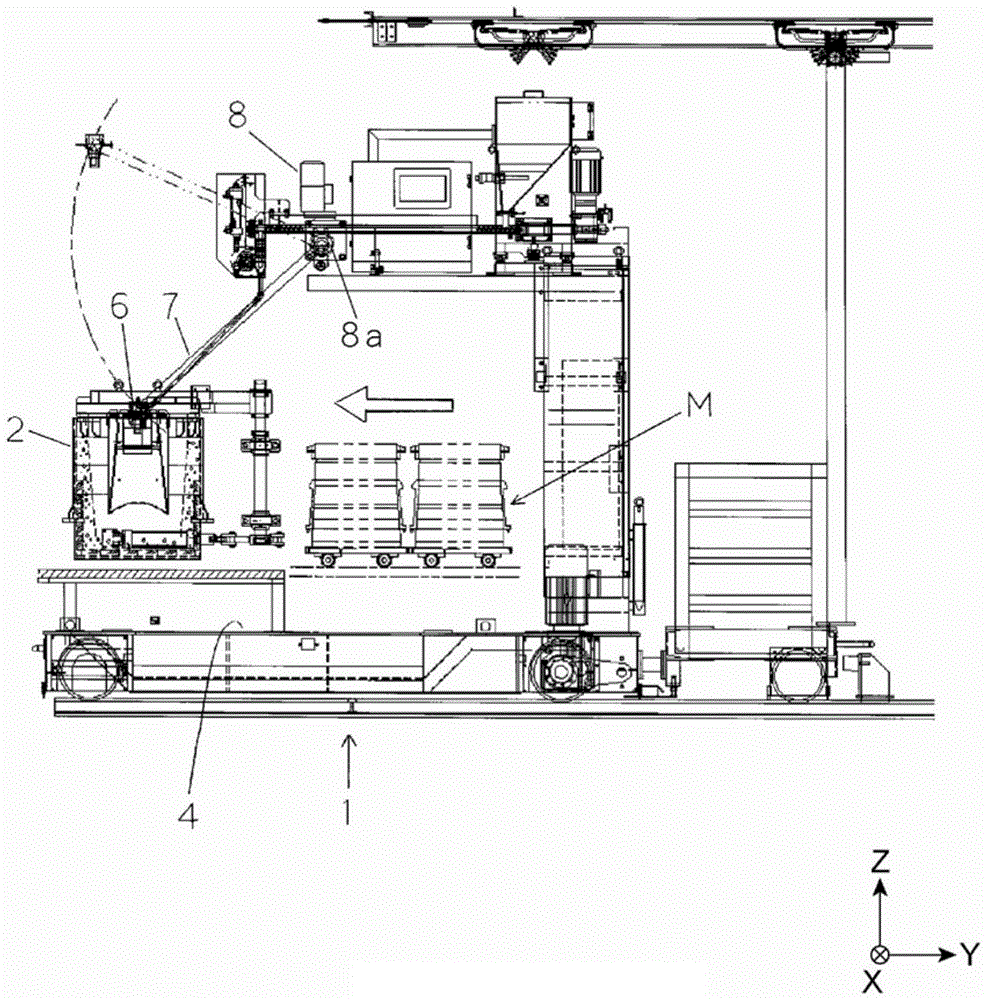

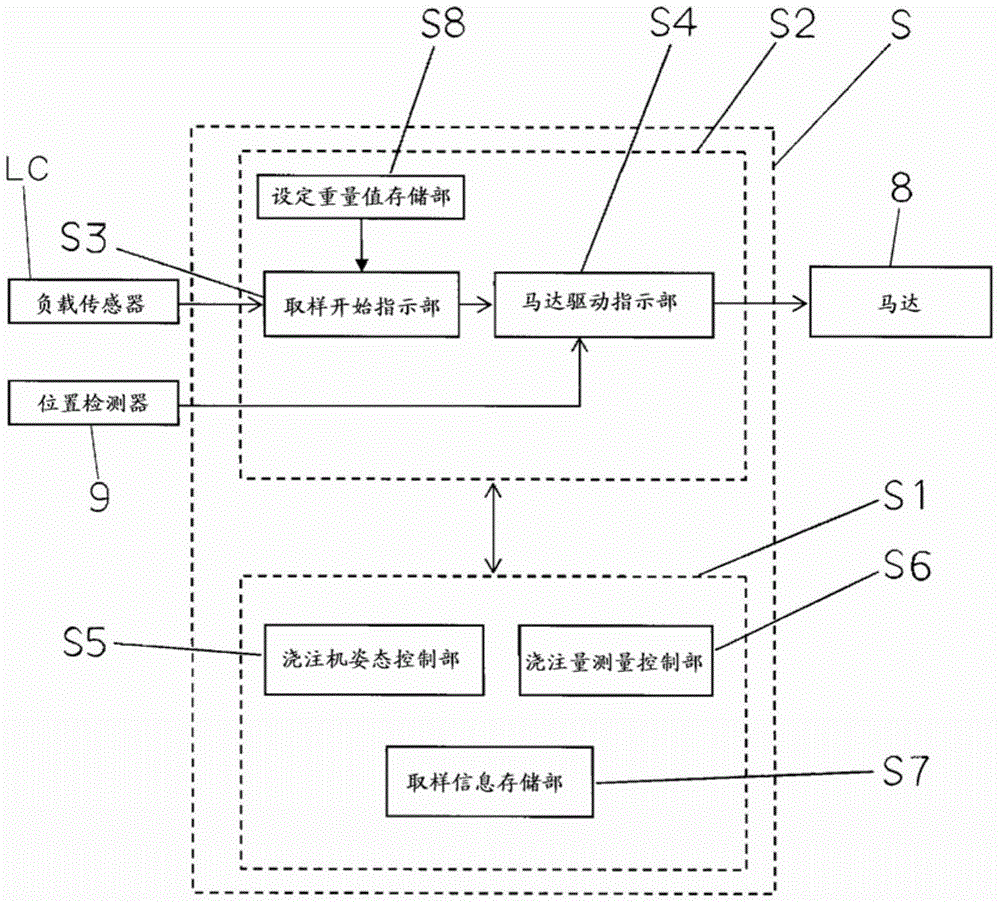

[0016] Hereinafter, the embodiment will be described in detail based on the drawings. figure 1 It is a front view which shows the automatic pouring apparatus concerning one embodiment. figure 2 yes figure 1 Side view of the automatic pouring device shown. In addition, for convenience of description, the conveyance direction of the mold M mentioned later is made into Y direction, the vertical direction is made into Z direction, and the direction perpendicular|vertical to Y direction and Z direction is demonstrated as X direction. Such as figure 1 As shown, a pair of rails L are provided on the ground along the Y direction. The mold M is conveyed along the rail L from a molding line (not shown) by a mold conveying mechanism not shown. A plurality of molds M are arranged on the track L at intervals of, for example, one pitch (one mold size), and the plurality of molds M are conveyed intermittently in the Y direction as a group of molds.

[0017] Moreover, the automatic pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com