Sterilization sampling integrated valve

An integrated, sampling port technology, applied in the field of bioreactor fermenters, can solve the problems of sterilization, sterilization time, quality cannot be programmed, standardized, many pipeline valves, and high cost, so as to save effective resources and operate without leakage. , sampling reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

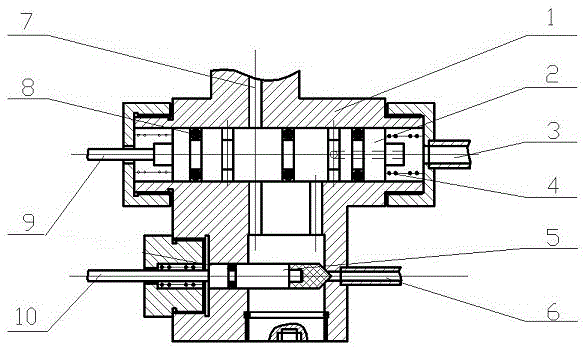

[0032] The present invention will be further described below in conjunction with the accompanying drawings of the specification.

[0033] A sterile sampling integrated valve, which is composed of a valve body 1 and two valve cores. The valve body 1 is a valve cavity composed of multiple passages, a tank body outlet 7 and a two-way steam interface 3 , Three-way sampling port 6, the two spools are composed of A spool 2 and B spool 5. The A spool 2 is a spool valve type main spool, the B spool 5 is a sampling port spool, and the A spool 2 moves in three positions: left position, middle position, and right position. The valve spool controls the valve ports on the valve body 1 to be disconnected. When the A spool 2 is moved to the left position, the inlet ring groove set on the A spool 2 conducts the steam interface 3 and the valve cavity passage. At this time, the valve cavity and the tank Body discharge port 7 is blocked, open sampling valve 5 to perform pre-sampling sterilization,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com