Oil-immersed current transformer live-wire sampling device and sampling method based thereon

A technology of current transformers and sampling devices, which is applied in the direction of sampling devices, inductors, sampling, etc., can solve the problems of contaminated oil sample analysis data, inaccuracy, etc., and achieve the goals of improving accuracy, reliable sampling, and preventing oil leakage at the valve port Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

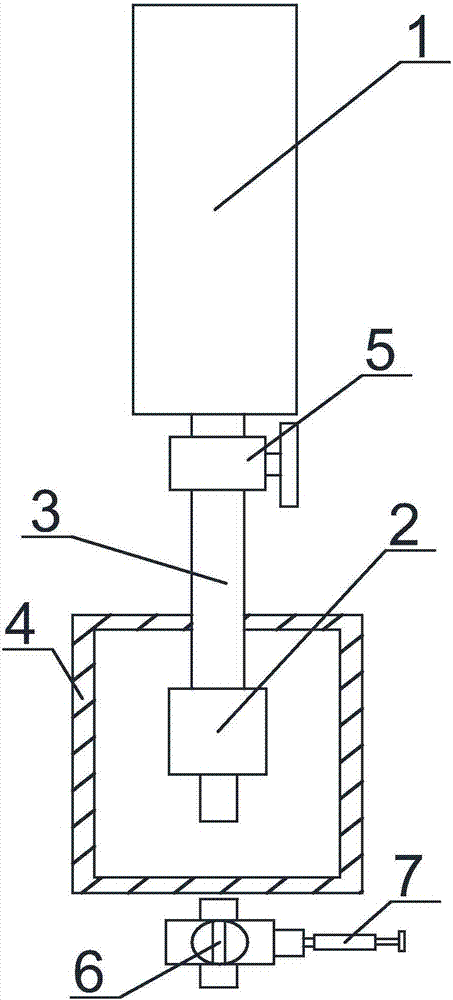

[0032] Such as figure 1 As shown, the oil-immersed current transformer live sampling device of the present invention includes a sampling valve 2 communicated with the current transformer 1 oil tank, and the current transformer 1 oil tank is connected with the sampling valve 2 through the connecting pipe 3, and the outside of the sampling valve 2 Covered with a protective cover 4, the sampling valve 2 is completely inside the protective cover 4. The connecting pipe 3 is a stainless steel pipe with an inner diameter of 4 mm and an outer diameter of 6 mm.

[0033] In the present invention, a connecting pipe is added to the sampling port of the current transformer oil tank, and the connecting pipe is downwardly connected to the sampling valve, which reduces the position of sampling and thereby reduces the risk of sampling, and realizes safe and reliable sampling; the sampling valve is installed on the protective cover Inside, on the one hand, the protective cover plays the role o...

Embodiment 2

[0035] Based on embodiment 1, the sampling valve 2 adopts a needle sampling valve, the front end of the sampling valve 2 is a sampling nozzle, and the rear end of the sampling valve 2 is a cylindrical sealing core, and the cylindrical sealing core is connected to the connecting pipe 3 . The inner hole diameter of the sampling nozzle of the sampling valve 2 is 5.0 mm-8.0 mm, and the inner hole diameter of the cylindrical sealing core of the sampling valve 2 is 1 cm. The structure of the sampling valve in the invention can ensure the tightness of oil taking, and make the oil sample flow out continuously and evenly, and prevent the waste of oil. The present invention optimizes the size of the sampling valve, the larger the diameter of the sampling nozzle, the poorer the sealing performance, and the larger the diameter of the sampling nozzle, the more oil samples it will flow out at one time; but the smaller the diameter of the sampling nozzle, the slower its sampling speed, low ...

Embodiment 3

[0037] Based on the above embodiments, the connection between the oil tank of the current transformer 1 and the connecting pipe 3, and the connection between the connecting pipe 3 and the sampling valve 2 are all welded connections. Welded connection, firm and reliable, effectively prevent oil leakage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bore diameter | aaaaa | aaaaa |

| Bore diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com