Fuel injection arrangement

A technology of fuel injection device and fuel injection valve, which is applied in the direction of fuel injection device, special fuel injection device, charging system, etc., can solve problems such as increasing the complexity of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The fuel injection device according to the invention is particularly suitable for large internal combustion engines, such as main or auxiliary engines of ships, engines for offshore applications or engines used at power plants for generating electricity. The invention is particularly advantageous in dual fuel engines which can operate on both liquid and gaseous fuels and where a small amount of liquid pilot fuel is used when the engine is operated in gaseous mode. However, the invention may also be used in other engines in which two or more fuel injectors are used per cylinder.

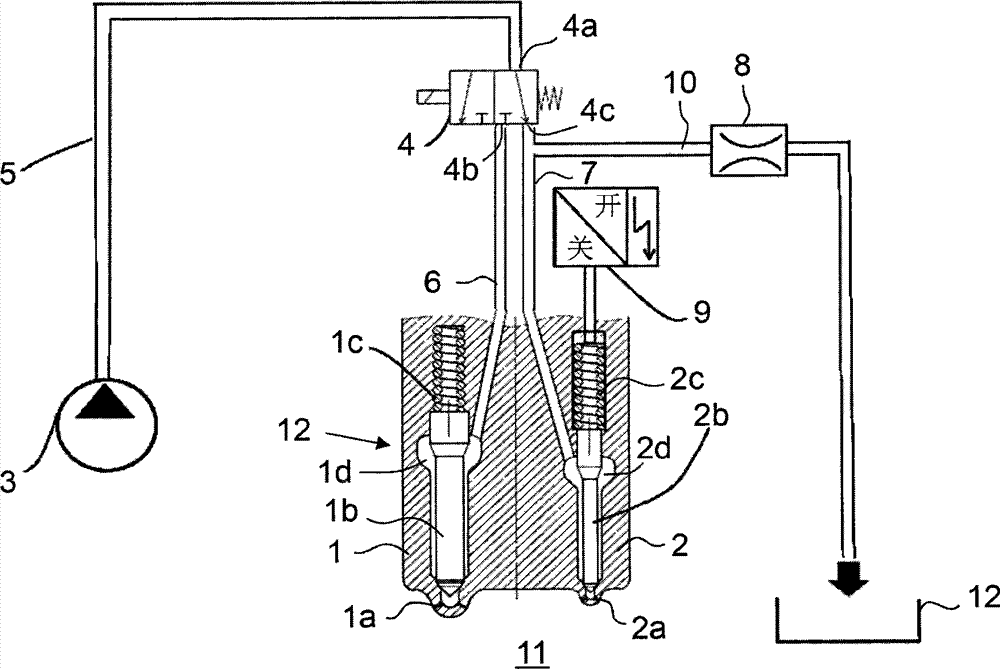

[0012] figure 1 A schematic diagram of a fuel injection device according to an embodiment of the present invention is shown. The fuel injection device comprises a first fuel injection valve 1 and a second fuel injection valve 2 which are arranged for injecting fuel into a cylinder 11 of a piston engine. The second fuel injection valve 2 is configured to inject a smaller amount of fuel than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com