Heating fabric based on flexible thick-film heater and temperature control method thereof

A heating element and thick film technology, applied in electric heating devices, ohmic resistance heating, clothing, etc., can solve the problems of affecting heating and holding time, carbon fiber can not be exposed, and resistance increase, so as to ensure effective heating time and increase warmth retention time, to ensure the effect of reasonable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

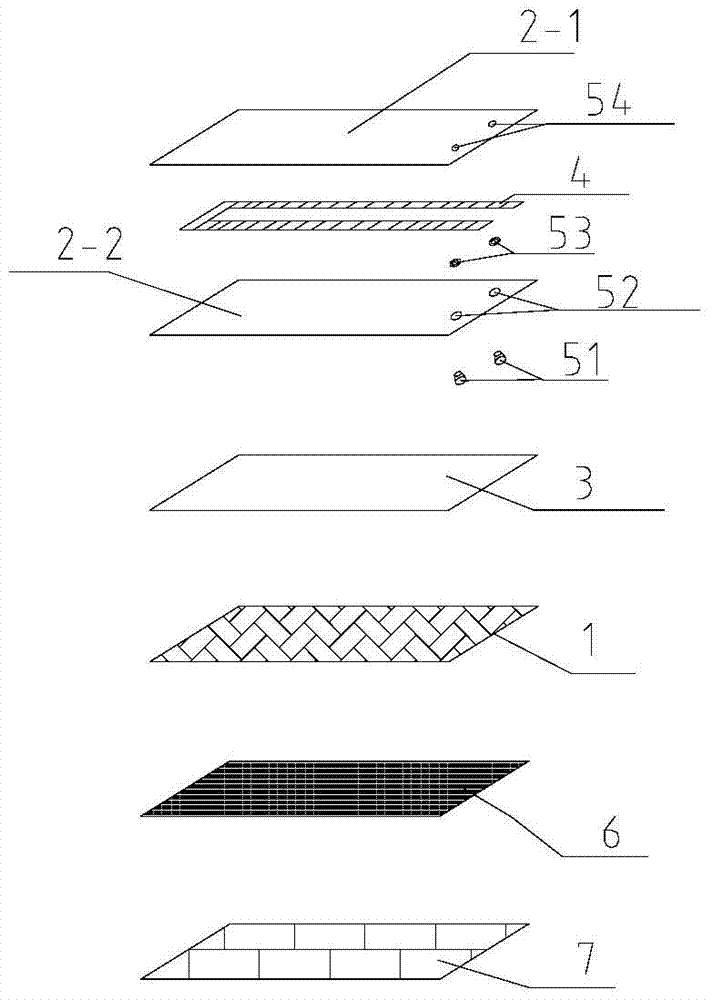

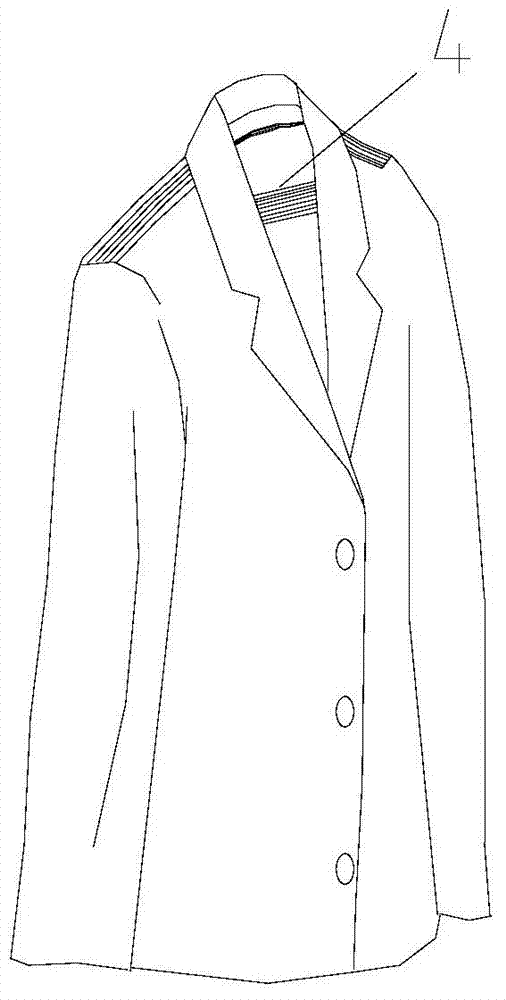

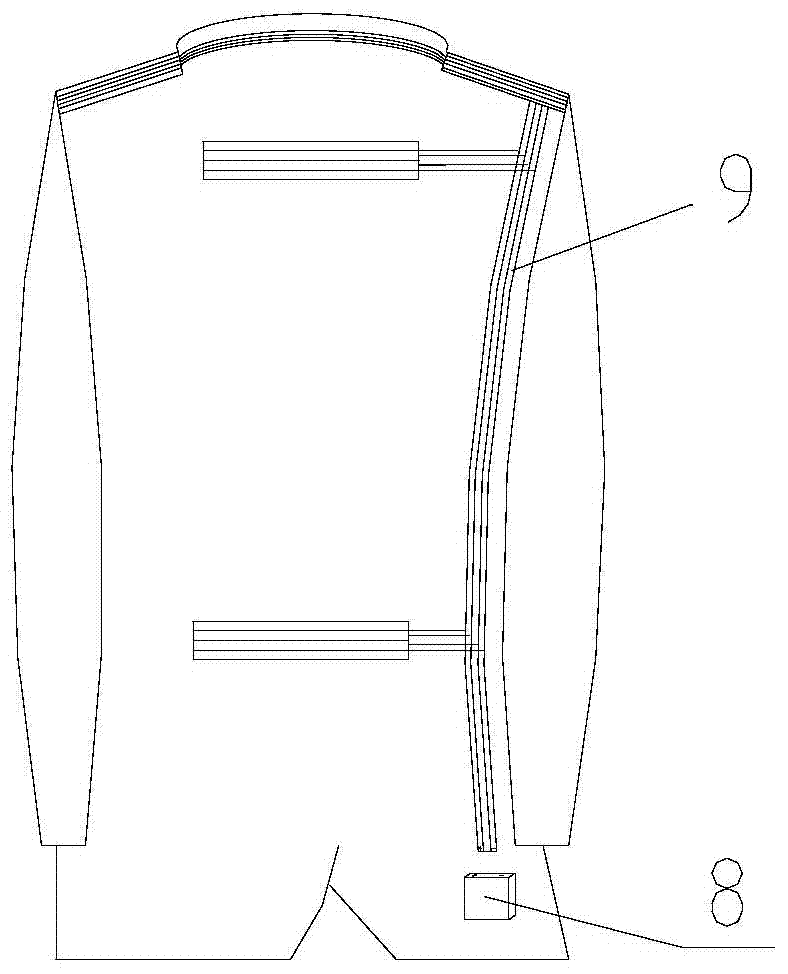

[0024] The schematic diagram of the structure of the heatable cloth is shown in figure 1 As shown, it includes a cloth layer 1 and two flexible substrate layers 2-1, 2-2. On the flexible substrate layer 2-1, a heating thick film circuit 4 is printed and burned at a high temperature, and the heating thick film circuit 4 is arranged between the flexible substrate layers 2-1 and 2-2 in a folded manner. The flexible base material layer is bonded to the cloth layer 1 through an adhesive layer 3; the contact point for connecting the external power supply is a riveting joint, including riveting nails 51 and conductive mesons 53, and the flexible base material layer has perforations 52, 54, The riveting nail 51 passes through the conductive meson 53 and the perforations 52 and 54 , and presses and connects the conductive meson 53 and the heating thick film circuit 4 . The other side of the cloth layer 1 is also provided with a heat reflection layer 6 made of tinfoil, heat emission co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com