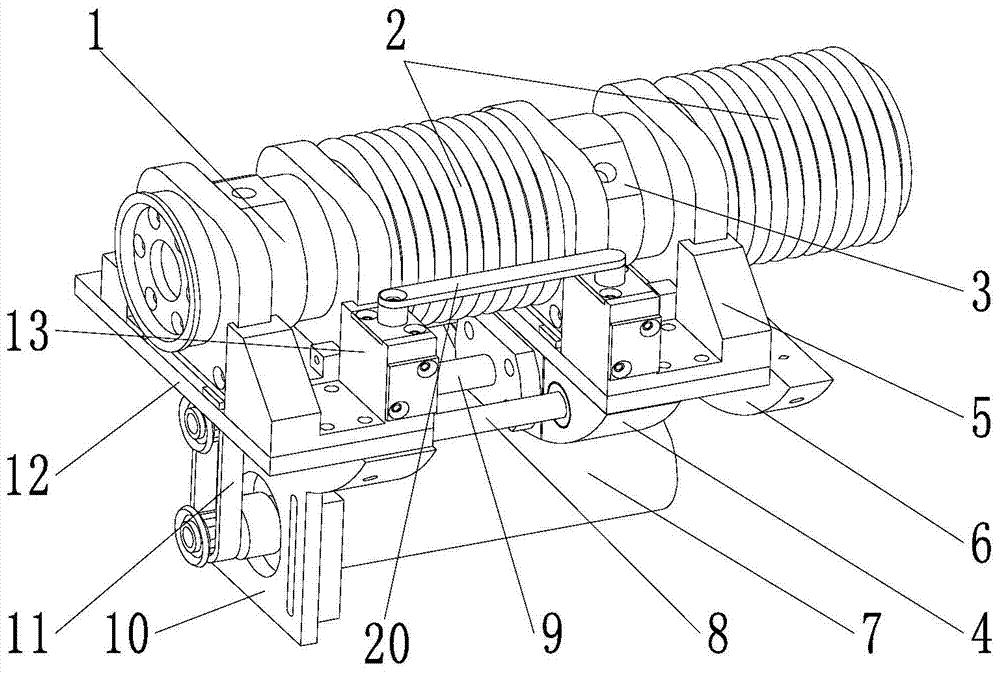

Digestive endoscopy conveying mechanism

A conveying mechanism and endoscope technology, applied in the field of medical devices, can solve the problems of high physical exertion, expensive operation facilities, high pollution, etc., and achieve the effects of preventing mutual pollution, accurate and reliable movement, and protecting the outer wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

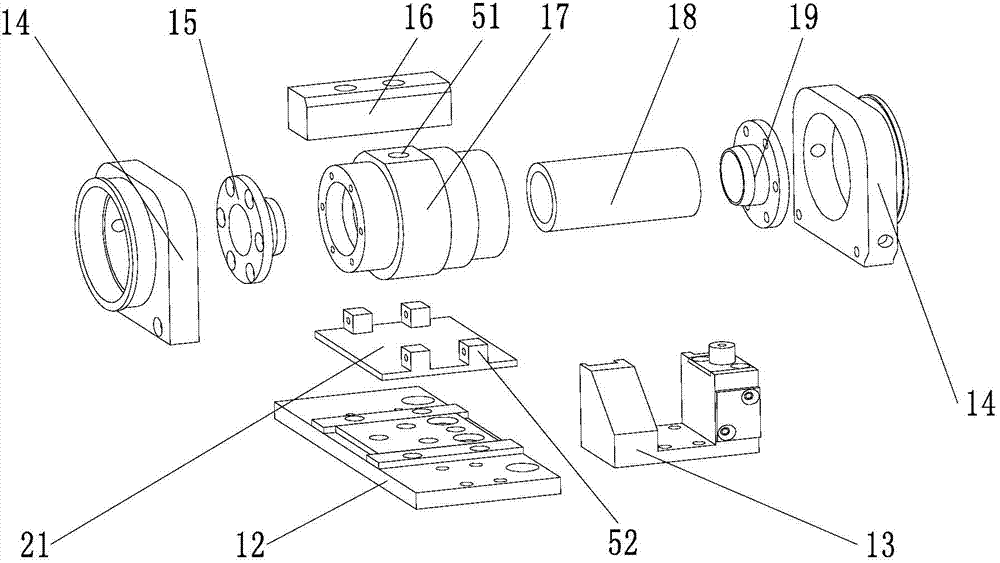

[0033] Such as figure 2 As shown, in this embodiment, both the fixed air clamp 1 and the dynamic air clamp 3 are integral structures, including an air clamp cylinder 17, a first gland 15, a second gland 19, a silicone tube 18 as a silicone clamping body, Air clamp end fixing seat 14, air clamp base 16, air clamp bottom plate 21 and air clamp locking mechanism 13, described air clamp cylinder body 17 is tubular structure, silicone tube 18 is arranged in the described air clamp cylinder body 17, described The first gland 15 and the second gland 19 are respectively installed on the two ends of the air clamp cylinder 17 along the axial direction, and the air clamp cylinder 17, the first gland 15, the second gland 19 and the silicone tube 18 constitutes an airtight air chamber arranged between the inner peripheral surface of the air clamp cylinder 17 and the outer peripheral surface of the silicone tube 18, the air clamp cylinder 17 is provided with air holes 51, during work, thro...

Embodiment 2

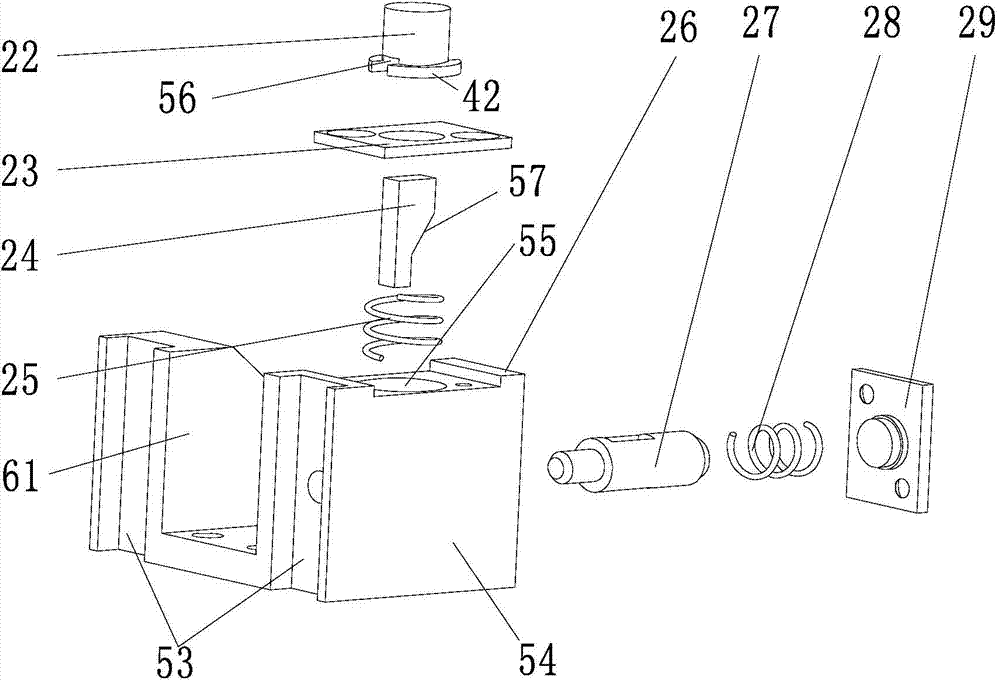

[0040] Such as Figure 5-6 As shown, in this embodiment, both the fixed air clamp 1 and the dynamic air clamp 3 are split structures, including an air clamp base 41, an air clamp upper cover 36, an air clamp clamping piece 39, a hinge 37, a self-locking buckle 40 and as The two silica gel half-membranes 38 of the silica gel clamping body, the air clamp base 41 are installed on the platen base 30 of the spring platen mechanism 12, and one side of the air clamp loam cake 36 is hinged with the air clamp base 41 by a hinge 37. The hinge 37 is a butterfly hinge, and the other side of the air clamp upper cover 36 is connected and locked with the air clamp base 41 through a self-locking buckle 40; There are grooves with the same depth, and the silicone half-membranes 38 are respectively arranged in the grooves of the air clamp base 41 and the air clamp upper cover 36, and are respectively fixed on the air clamp upper cover 36 and the air clamp by the air clamp clamping piece 39. On ...

Embodiment 3

[0045] Such as Figure 7-8As shown, in this embodiment, both the fixed gas clamp 1 and the dynamic gas clamp 3 are split structures. The fixed gas clamp 1 of this embodiment is the same as that of embodiment 2. The difference between this embodiment and embodiment 2 is that There is a load cell 45, and the specific structure is: including a fixed base 47, a load cell 45, a fixed nut 46, a force feedback air clamp base 43, an air clamp upper cover 36, an air clamp clamping piece 39, and two silicone half-membranes 38 , hinge 37 and spring self-locking buckle 44, wherein the fixed base 47 is installed on the platen base 30 of the spring platen mechanism 12 through screws, and a pair of opposite corners of the fixed base 47 are provided with two sensor brackets 58, force feedback The air clamp base 43 is provided with two sensor support plates 59, and two load cells 45 are arranged in parallel between the fixed base 47 and the force feedback air clamp base 43, and one end of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com