Shutter device

A shutter, linear motor technology, applied in the shutter, optics, instruments and other directions, can solve the problems of poor stability, poor position control accuracy, large vibration, etc., to achieve the effect of improving heat resistance, stable overall structure, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

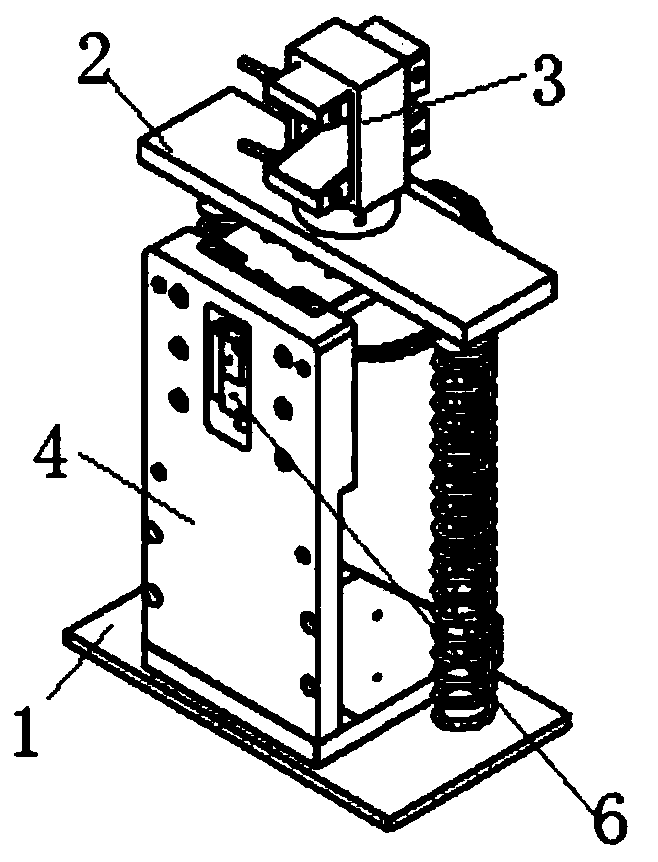

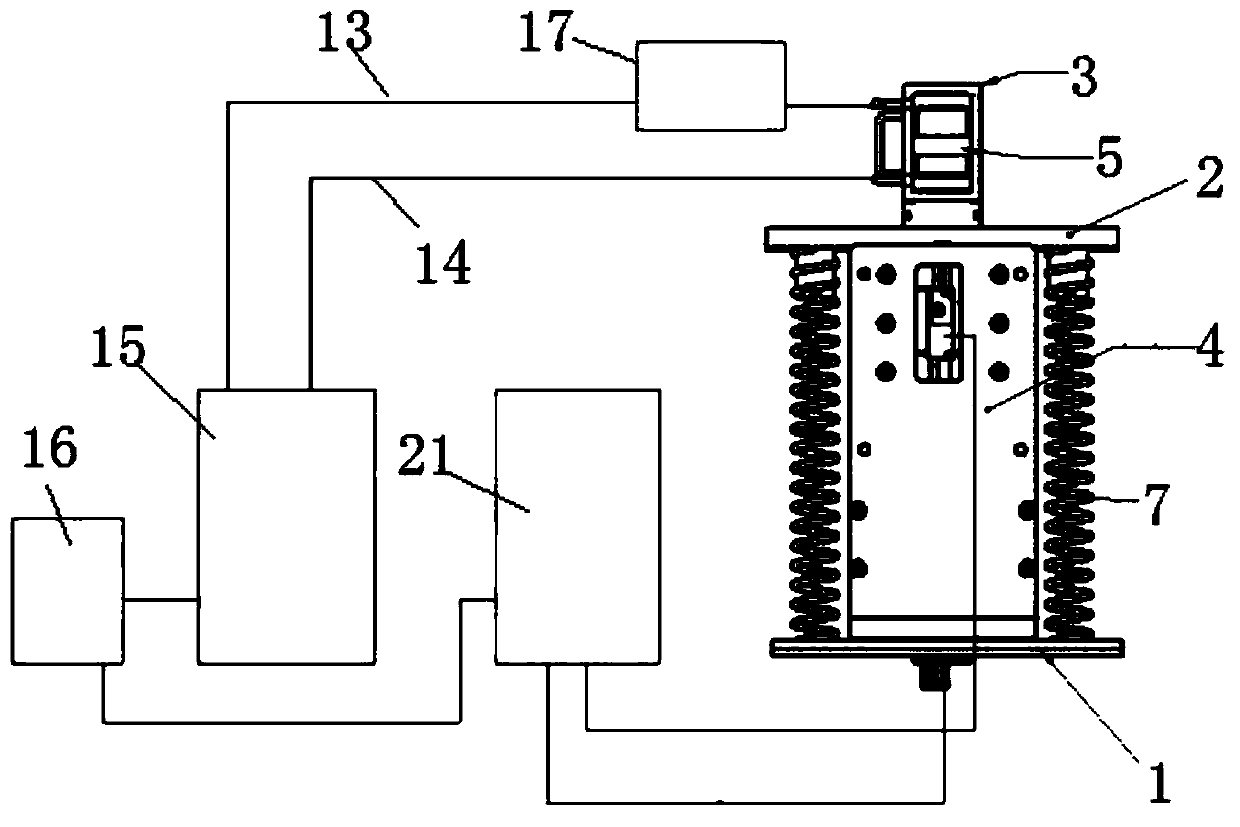

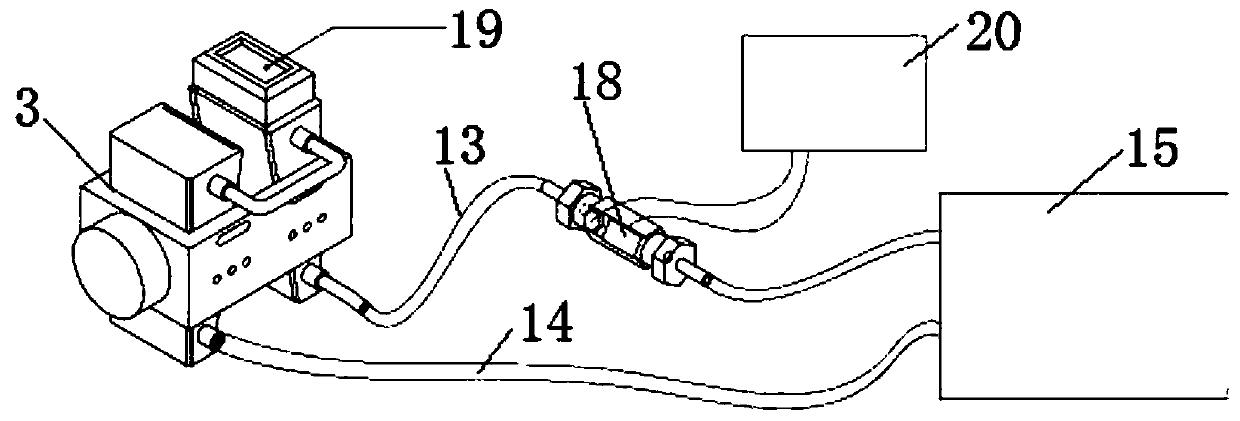

[0028] The invention provides a shutter device, such as Figure 1-Figure 5 As shown, it includes a fixed platform 1, an adapter plate 2 and a water-cooled head module 3. The fixed platform 1 is provided with a voice coil linear motor 4, and the top of the voice coil linear motor 4 is connected with an adapter plate 2. There is a first through hole, and a second through hole is opened on the water cooling head module 3, organic rice screws are movably connected in the first through hole and the second through hole, so that the top of the adapter plate 2 passes through the organic rice screw and the water cooling head module The 3 axis holes are matched and connected so that the water cooling head module 3 can move axially relative to the adapter plate 2 but cannot move radially. The water cooling head module 3 is provided with a light hole 5; After passing through the adapter plate 2, it is connected to the bottom of the water-cooled head module 3; a grating scale 6 is installe...

Embodiment 2

[0034] like Image 6 As shown, in another embodiment, the spring 7 used in the shutter device of the present invention is replaced by a constant force magnetic spring. Constant force magnetic springs, unlike traditional mechanical springs, can provide a constant push or pull force over the entire travel range. This series of products adopts an innovative magnetic circuit design, which realizes gravity compensation and offset through a magnetic field, and has a simple structure, including only two components, the stator and the mover. The constant force magnetic spring is a completely passive device, which can achieve constant force output without any external energy supply, such as hydraulic pressure, air pressure, power supply, etc. It is the most ideal choice for applications that require high system safety factors, constant thrust or constant tension, including smooth tension and recovery, balance mechanism applications, tension load applications, gravity compensation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com