Vertical type rubbish compression technology

A technology of garbage compression and garbage, applied in the field of sanitation, can solve the problems of large extrusion force, secondary pollution, cumbersome process, etc., and achieve the effect of improving service life, large daily processing tonnage and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

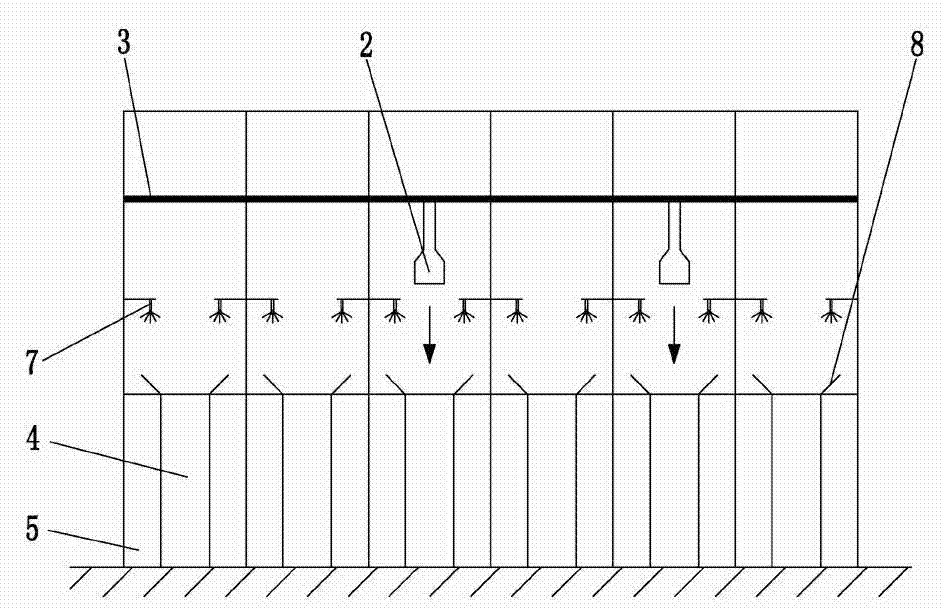

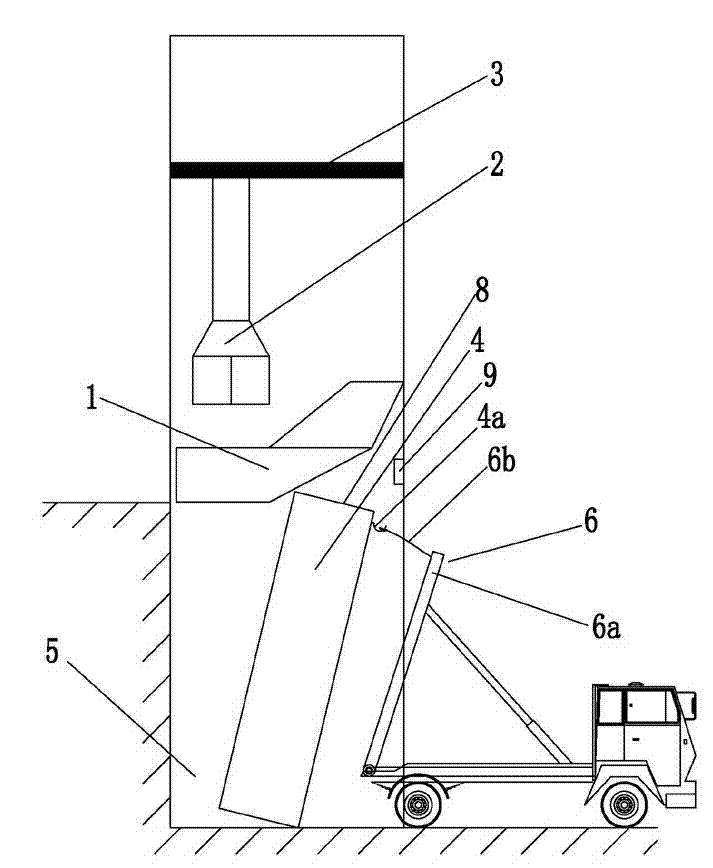

[0018] Such as Figure 1-2 As shown, a vertical garbage compression process includes weighing and measuring steps, collection vehicle unloading steps, garbage compression steps, and full container loading steps in sequence, and the garbage compression step is performed by vertical compression equipment; full container The loading step is carried out by the wire drawing mechanism 6 of the transfer vehicle 17.

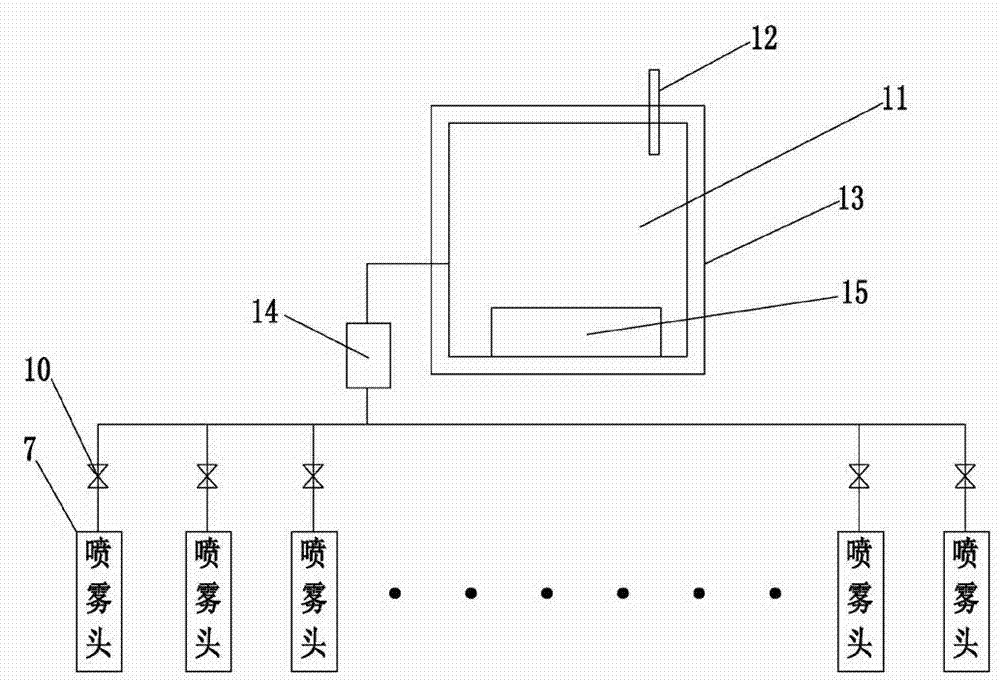

[0019] Wherein, the container 4 that is used to load rubbish is provided with a plurality of and is arranged in the corresponding berth 5 one by one, and each container 4 is all correspondingly equipped with a discharge chute 1, and container 4 is placed vertically, and the top of container 4 is provided with Feeding door 8, the upper edge of container 4 is provided with suspension hook 4a; The motion guiding platform 3 moves to the top of the container 4 that needs to be compressed. The up and down movement of the compression hammer 2 is controlled by the hydraulic cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com