Preparation method of isopropanolamine

A technology of isopropanolamine and propylene oxide, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of amino hydroxyl compounds, etc., can solve the problems of high energy consumption, save energy, reduce by-products, and reduce equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

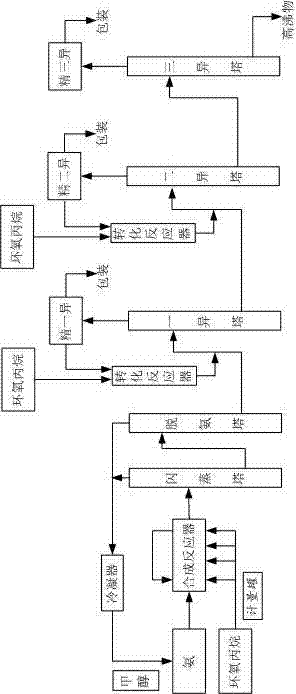

[0020] Example 1: If monoisopropanolamine is sold as the main product, such as figure 1 As shown,

[0021] (1) Inject 5 parts of solution A into the synthesis reactor, and then 1 part of the same mole of propylene oxide from the metering tank pressurized 0.1~0.2Mpa into the synthesis reactor to react with solution A to produce solution B. The temperature during reaction Control at 30~40℃;

[0022] (2) The solution B in the synthesis reactor is removed by the external circulation pump, cooled to the reaction temperature by the heat exchanger, and then sprayed into the synthesis reactor through the static atomizing ejector in the synthesis reactor to accelerate the reaction of the materials. After the reaction is completed in 2-8 hours, solution C is obtained, wherein the reaction temperature in the synthesis reactor is 30-40°C, and the reaction pressure is 0.2-0.4 MPa;

[0023] (3) The solution C is sent to the flash tower to remove 90-96% of the ammonia, and the pressure is reduced...

Example Embodiment

[0028] Example 2: If diisopropanolamine is sold as the main product, such as figure 1 As shown,

[0029] (1) Inject 5 parts of solution A into the synthesis reactor, and then 2 parts of the same mole of propylene oxide from the metering tank pressurized 0.1~0.2Mpa into the synthesis reactor to react with solution A to produce solution B. The temperature during reaction Control at 30~40℃;

[0030] (2) The solution B in the synthesis reactor is removed by the external circulation pump, cooled to the reaction temperature by the heat exchanger, and then sprayed into the synthesis reactor through the static atomizing ejector in the synthesis reactor to accelerate the reaction of the materials. After the reaction is completed in 2-8 hours, solution C is obtained, wherein the reaction temperature in the synthesis reactor is 30-40°C, and the reaction pressure is 0.2-0.4 MPa;

[0031] (3) The solution C is sent to the flash tower to remove 90-96% of the ammonia, and the pressure is reduced ...

Example Embodiment

[0036] Example 3: If triisopropanolamine is sold as the main product, such as figure 1 As shown,

[0037] (1) Inject 5 parts of solution A into the synthesis reactor, and then 2 parts of the same mole of propylene oxide from the metering tank pressurized 0.1~0.2Mpa into the synthesis reactor to react with solution A to produce solution B. The temperature during reaction Control at 30~40℃;

[0038] (2) The solution B in the synthesis reactor is removed by the external circulation pump, cooled to the reaction temperature by the heat exchanger, and then sprayed into the synthesis reactor through the static atomizing ejector in the synthesis reactor to accelerate the reaction of the materials. After the reaction is completed in 2-8 hours, solution C is obtained, wherein the reaction temperature in the synthesis reactor is 30-40°C, and the reaction pressure is 0.2-0.4 MPa;

[0039] (3) The solution C is sent to the flash tower to remove 90-96% of the ammonia, and the pressure is reduced...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap