Nylon auxiliary agent oil and preparation method and use thereof

An additive oil, nylon technology, applied in the field of polymer synthetic materials, can solve the problems affecting product strength and wear resistance, poor dispersion of powder lubricating materials, etc., to achieve long service life, reduced friction coefficient, self-lubricating good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] Example 1

[0021] 100 parts by weight of nylon additive oil, including the following parts by weight: 88 parts of 12-hydroxy stearate thickened grease, 2 parts of antioxidant 1010, 2 parts of modified montmorillonite, 5 parts of active bright yellow K6G and 3 parts of general-purpose compatible toughening agent ESC-C2330.

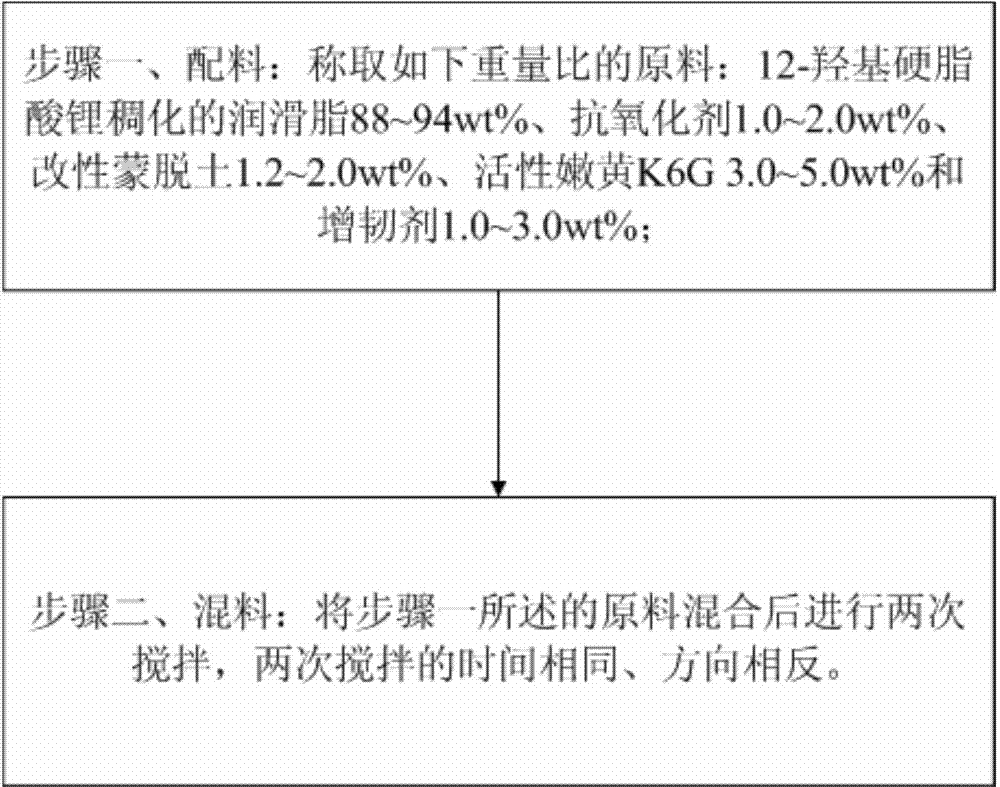

[0022] The preparation steps of the above nylon auxiliary oil are:

[0023] Step 1. Ingredients: Weigh the following parts by weight: 88 parts of 12-hydroxystearate thickened grease, 2 parts of antioxidant 1010, 2 parts of modified montmorillonite, 5 parts of active bright yellow K6G and 3 A general-purpose compatible toughening agent ESC-C2330;

[0024] Step 2. Mixing: After mixing the raw materials in Step 1, agitate twice, the time of the two mixing is the same, the direction is opposite, and the mixing time is 10 min.

[0025] The above-mentioned nylon auxiliary oil is used for the preparation of cast nylon. The caprolactam monomer and nylon auxiliary o...

Example Embodiment

[0027] Example 2

[0028] 100 parts by weight of nylon auxiliary oil, including the following parts by weight: 94 parts of 12-hydroxystearate lithium thickened grease, 1 part of antioxidant 1010, 1 part of modified montmorillonite, 3 parts of active bright yellow K6G and 1 part of general-purpose compatible toughening agent ESC-C2330.

[0029] The preparation steps of the above nylon auxiliary oil are:

[0030] Step 1. Ingredients: Weigh the following parts by weight: 94 parts of 12-hydroxy stearate thickened grease, 1 part of antioxidant 1010, 1 part of modified montmorillonite, 3 parts of active bright yellow K6G and 1 A general-purpose compatible toughening agent ESC-C2330;

[0031] Step 2. Mixing: After mixing the raw materials in Step 1, stir twice, the two stirring times are the same but in opposite directions, and the stirring time is 30 minutes.

[0032] The above-mentioned nylon auxiliary oil is used for the preparation of cast nylon. The caprolactam monomer and the nylon aux...

Example Embodiment

[0034] Example 3

[0035] 100 parts by weight of nylon auxiliary oil, including the following raw materials: 91 parts by 12-hydroxystearate lithium thickened grease, 1.5 parts of antioxidant 1010, 1.5 parts of modified montmorillonite, 4 parts of active bright yellow K6G and 2 parts of general-purpose compatible toughening agent ESC-C2330.

[0036] The preparation steps of the above nylon auxiliary oil are:

[0037] Step 1. Ingredients: Weigh the following parts by weight: 91 parts of 12-hydroxy stearate thickened grease, 1.5 parts of antioxidant 1010, 1.5 parts of modified montmorillonite, 4 parts of active bright yellow K6G and 2 A general-purpose compatible toughening agent ESC-C2330.

[0038] Step 2. Mixing: After mixing the raw materials in Step 1, stir twice, the two stirrings have the same time but opposite directions, and the stirring time is 20 min.

[0039] The above-mentioned nylon auxiliary oil is used for the preparation of cast nylon. The caprolactam monomer and nylon au...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unnotched impact strength | aaaaa | aaaaa |

| Heat resistant | aaaaa | aaaaa |

| Unnotched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap