RGB (red, green, blue) high power LED (light-emitting diode) intelligent liner lamp based on ultra-narrow aluminum substrate structure

A high-power, aluminum-substrate technology, applied in the parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of reducing the reliability and stability of lamps, detrimental to the aesthetics of lamps, and difficulty in post-maintenance, etc. Achieve the effect of being beneficial to assembly and post-maintenance, easy wiring, and saving profile materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

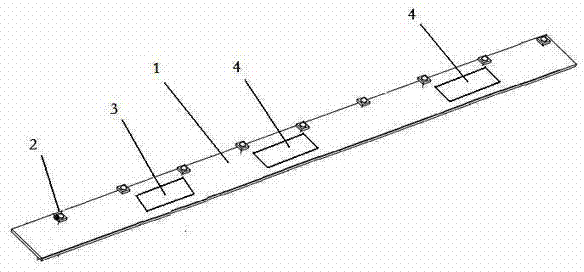

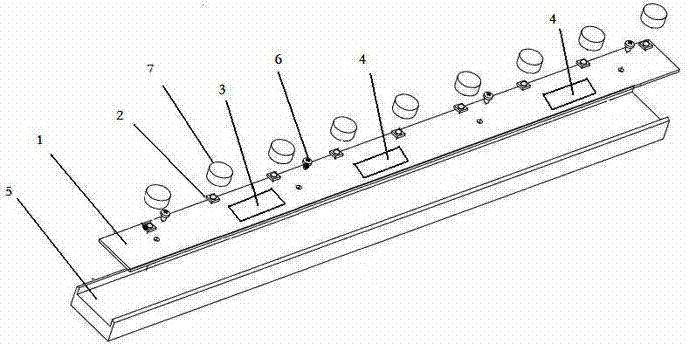

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] At present, people in the industry usually think that the heat generation of RGB high-power LED particles is much more serious than that of the drive circuit and control circuit, because they are worried that the heat generation of RGB high-power LED particles will affect the control circuit and drive circuit, so that the chips in the circuit will be damaged. Heat and damage, and then affect the efficiency of lamps and lanterns.

[0022] However, this is not the case. In the present invention, the first temperature rise test is carried out, the driving circuit and the control circuit are separately arranged from the RGB high-power LED particles, the driving circuit and the driving circuit are arranged on the FR-4 substrate, and the RGB high-power LED particles are arranged on the aluminum substrate . The temperature rise test was carried out under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com