Direct voltage splitting circuit supporting multi-level technology

A DC voltage and voltage dividing circuit technology, applied in the direction of irreversible DC power input conversion to AC power output, AC power input conversion to DC power output, electrical components, etc., can solve voltage unit voltage breakdown, capacitor unit Problems such as uneven voltage and uneven voltage, to prevent breakdown by withstand voltage and ensure voltage equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

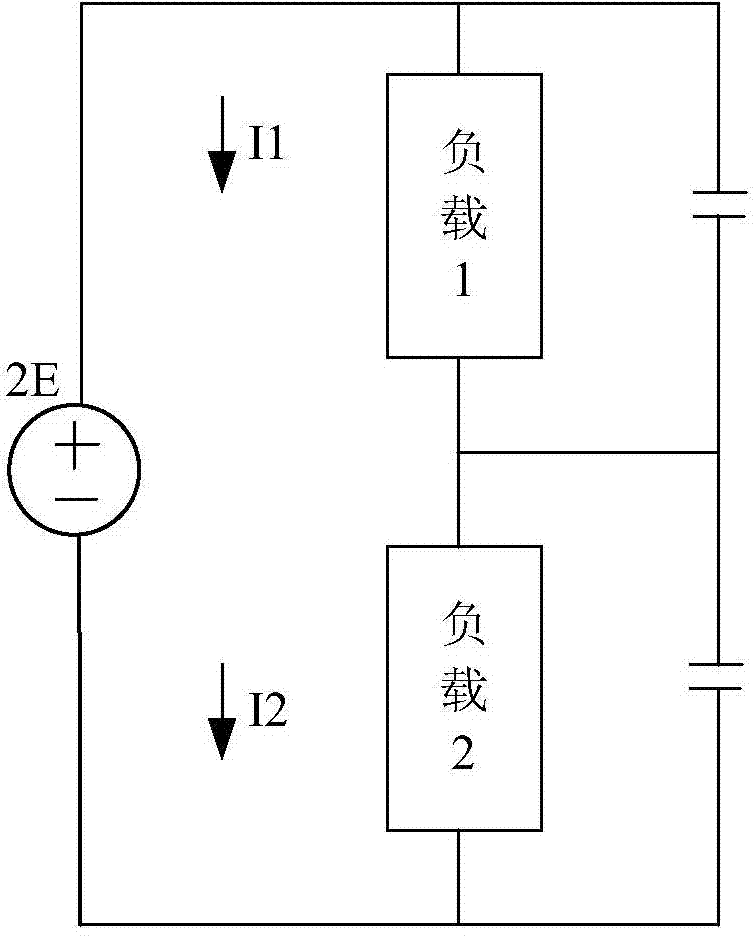

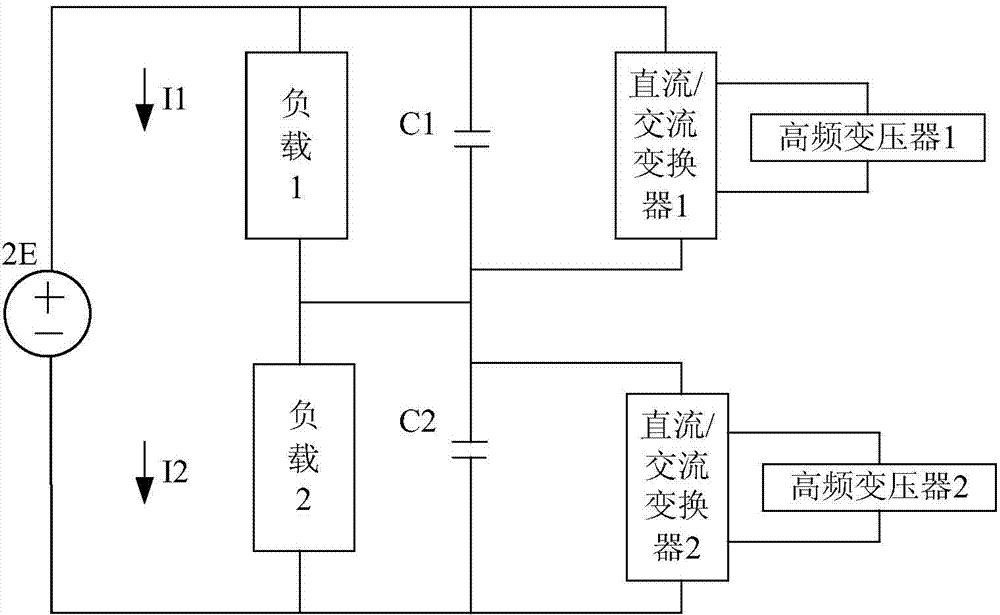

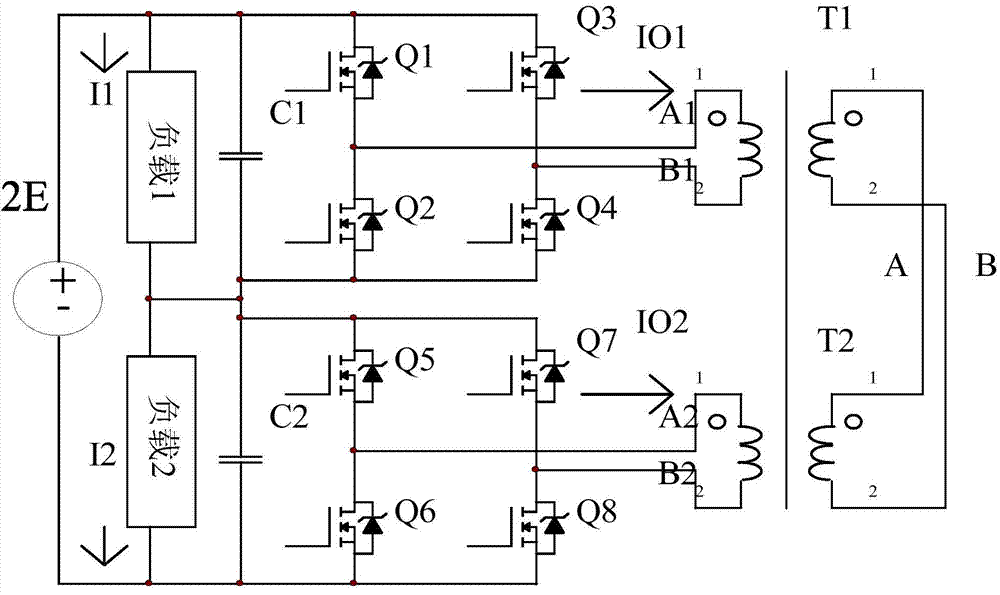

[0031] It can be seen from the background technology that in the DC voltage equalizing circuit of multi-level technology, the cause of voltage breakdown of voltage units is that the energy of different voltage units is different due to the unbalanced load voltage of different voltage units. deviation. Therefore, in order to solve this problem, in the DC voltage equalizing circuit of the multi-level technology in the embodiment of the present invention, for two or more voltage units used to share the DC voltage, each voltage unit is connected to a DC / AC converter and a high-frequency transformer, in which the high-voltage inverters of different voltage units have the same structure, the primary side is connected with the same polarity, and the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com