Heating reaction kettle

A technology for heating reaction kettles and furnaces, which is applied in chemical/physical/physical-chemical stationary reactors, mixers, chemical/physical/physical-chemical processes, etc. Space, inconvenient installation and other problems, to achieve the effect of simple structure, good stirring effect and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

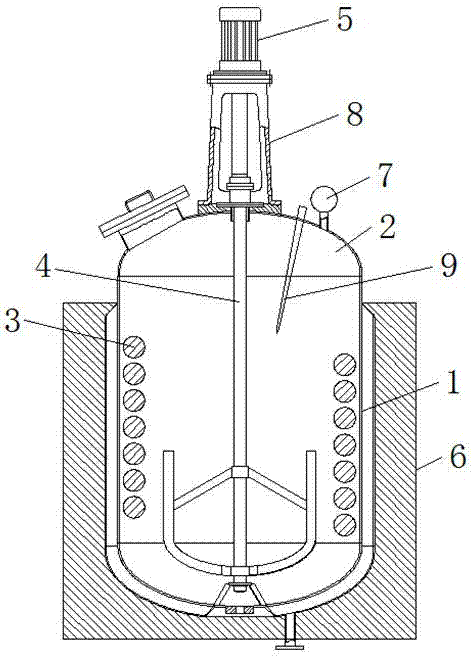

[0017] See figure 1 , the present invention has kettle body 1, kettle cover 2, cooling coil 3, agitator 4 and motor 5; kettle cover 2 is airtightly connected with kettle body 1; cooling coil 3 is arranged in kettle body 1; Type agitator, the agitator 4 is arranged in the kettle body 1, and its central axis coincides with the central axis of the kettle body 1; a magnetic coupling 8 is connected in series between the motor 5 and the agitator 4; there is also a heating furnace device 6; the heating furnace device 6 is cylindrical and covered on the outer wall of kettle body 1 .

[0018] An explosion-proof membrane device 7 is installed on the upper end of the kettle body 1 through a connecting pipe and a connecting valve.

[0019] The upper end of the kettle body 1 is also provided with a temperature measuring tube 9; one end of the temperature measuring tube 9 extends into the kettle body 1, and one end extends out of the kettle body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com