Cycle recovery method of formic acid solvent in metronidazole production process

A production process, recycling technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

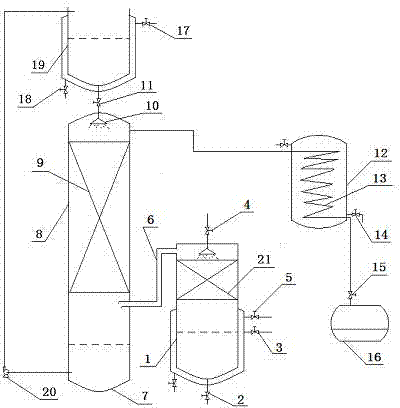

[0019] When implementing the present invention, first add dilute phosphoric acid to the dehydration kettle 19, open the heating medium outlet valve 17 and the heating medium inlet valve 18, and remove the moisture in the dilute phosphoric acid by heating; Phosphoric acid becomes polyphosphoric acid; then the phosphoric acid valve 11 is opened to allow viscous polyphosphoric acid to flow into the packing layer, absorb water while flowing downward, and finally flow into the phosphoric acid storage tank 7. Then add an appropriate amount of hydroxylated liquid to the evaporator 1, and then open the heating steam valve 5 and the cooling water inlet valve 14 in sequence. Later, the hydroxylated liquid in the evaporator 1 boils, and the generated steam rises to the packing layer 21 to remove solid entrainment, and then enters the bottom of the water absorption tower 8 from the connecting pipe 6 . During the flow of the steam in the water absorption tower 8, the moisture is absorbed b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap