Hydraulic system for realizing sanitation truck sweeper brush/suction nozzle floating

A hydraulic system and sweeping technology, applied in fluid pressure actuating devices, road cleaning, servo motors, etc., can solve problems such as frequent replacement, prolong the service life, reduce the number of sweeping adjustments, and ensure durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

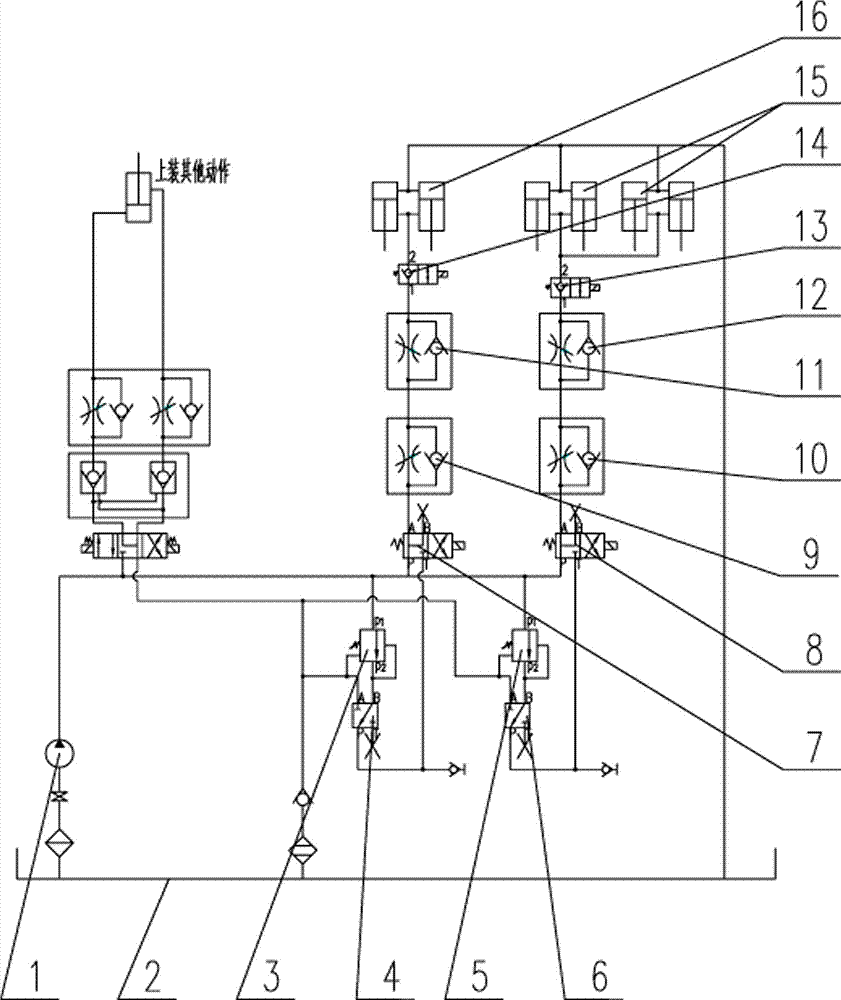

[0012] The hydraulic system for realizing the cleaning of the sanitation vehicle / floating suction nozzle of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0013] (1) As shown in the figure, the hydraulic system for sanitation vehicle sweeping / suction nozzle floating in the present invention includes a hydraulic gear pump 1, a hydraulic oil tank 2, a superimposed pressure reducing valve I3, a PB valve plate I4, and a superimposed pressure reducing valve II5 , PB valve plate II6, two-position four-way valve I7, two-position four-way valve II8, superimposed one-way throttle valve I9, superimposed one-way throttle valve II10, one-way throttle valve I11, one-way throttle valve Ⅱ12, 2-position 2-way valve Ⅱ13, 2-position 2-way valve Ⅰ14, sweeping cylinder 15 and suction nozzle cylinder 16; the oil outlet of hydraulic gear pump 1 passes through the hydraulic pipeline and the p1 port and 2nd port of superimpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com