LED lamp with vertical ventilation and heat dissipation structure

A technology of LED lamps, ventilation and heat dissipation, which is applied in the direction of lighting and heating equipment, damage prevention measures of lighting devices, semiconductor devices of light-emitting components, etc. It is very obvious and affects the service life of LED lighting, etc., to avoid the effect of temperature rise, simple structure, convenient assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

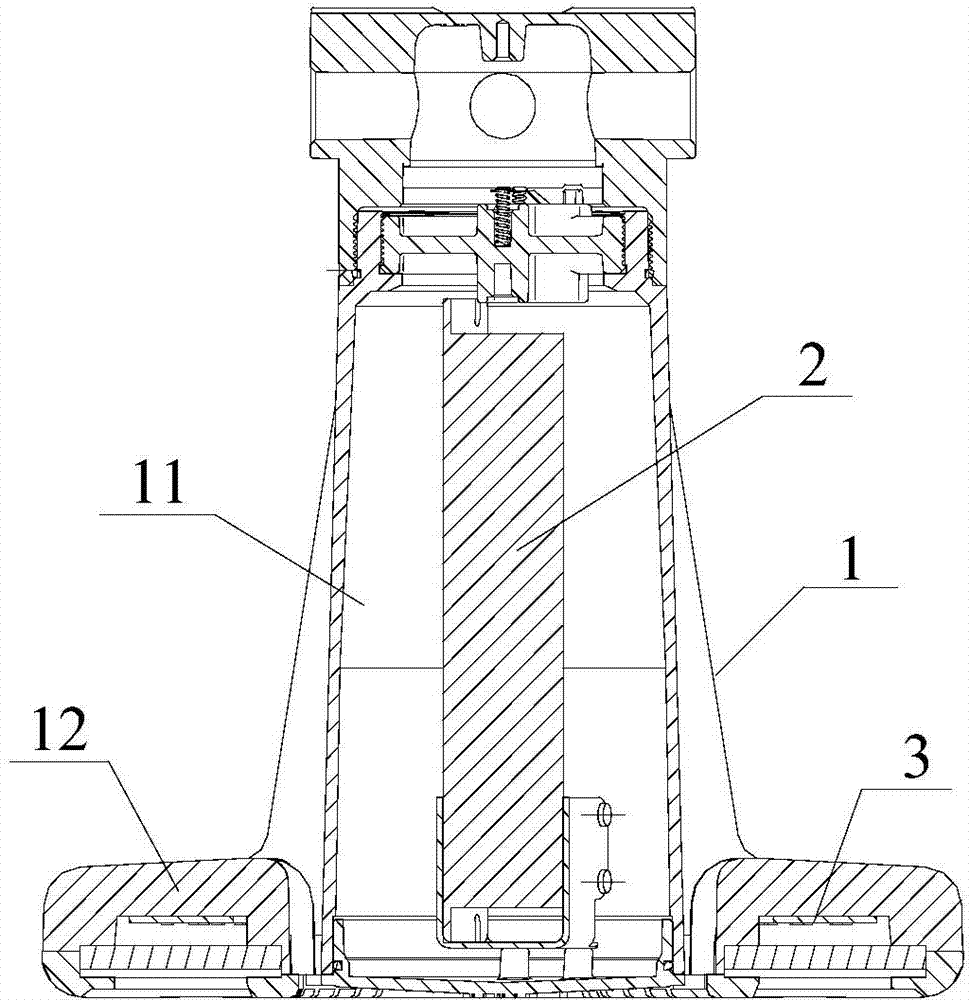

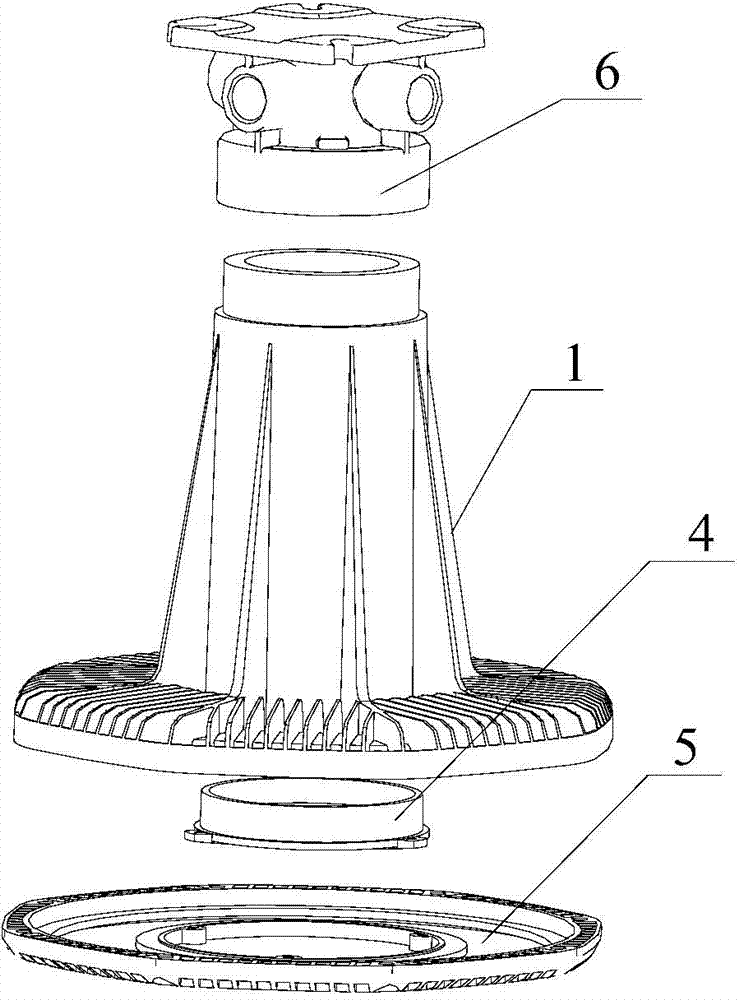

[0030] Such as image 3 As shown: a LED lamp with a vertical ventilation and heat dissipation structure provided in this embodiment also includes a lamp cover 4, a light-transmitting cover 5 and a lamp installation head 6. One end of the lamp cover 4 is provided with an opening, and the end surface is An annular cylinder, the outer diameter of the cylinder is adapted to the inner diameter of the through hole arranged at the center of the mouth of the lamp housing, and the center of the light-transmitting cover 5 is provided with a diameter corresponding to the outer diameter of the cylinder on the lamp cover 4. Adapted central hole 51, the outer diameter of the transparent cover 5 is adapted to the inner diameter of the outer ring of the mouth of the lamp housing.

[0031] Such as Figure 4 As shown: the outer edge of the light-transmitting cover 5 is provided with a thread 52 for connecting with the mouth of the lamp housing, and the edge of the central hole of the light-tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com