Fabric weft density measuring method and equipment

A measurement method and fabric technology, which is applied in the field of textile printing and dyeing, can solve the problems of reducing the production efficiency of the fabric process, the inability to achieve online automatic measurement, and the large error of the weft density value, so as to ensure quality, ensure stability, and reduce measurement errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

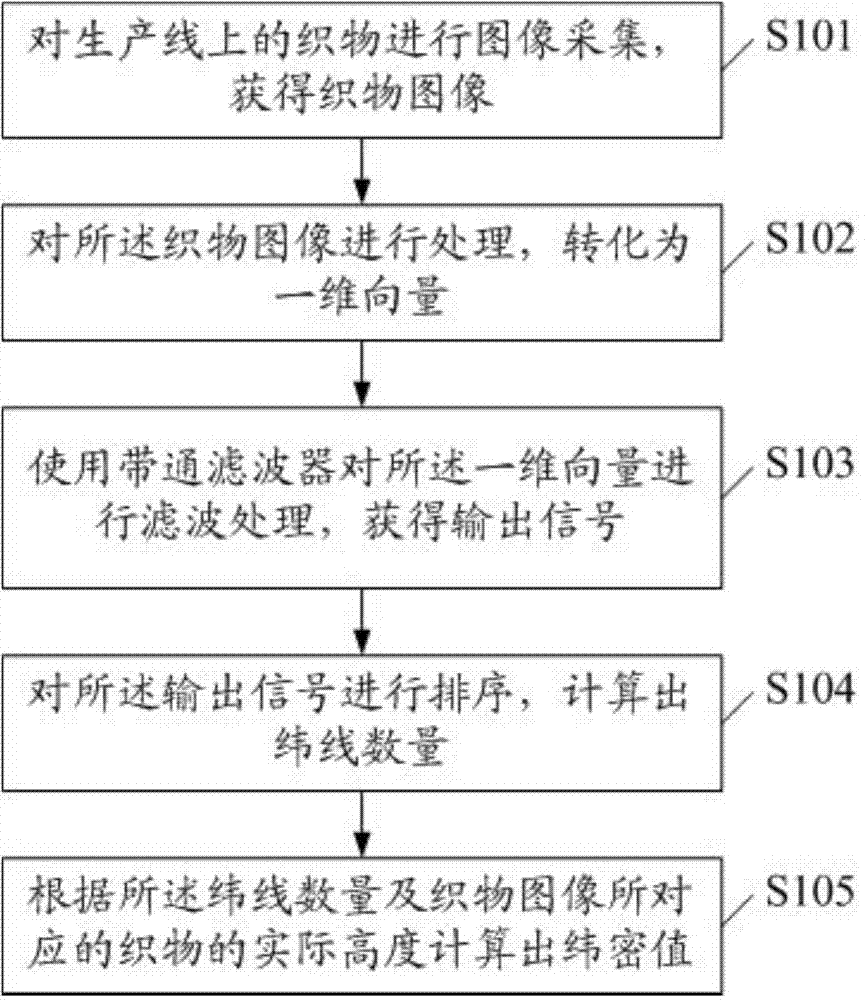

[0045] figure 1 It is the flow chart of the first embodiment of the fabric weft density measuring method of the present invention, comprising:

[0046] S101. Collect images of fabrics on the production line to obtain fabric images.

[0047] During image acquisition, it is necessary to capture the moving fabric on the production line through the shooting device to obtain the fabric image.

[0048] The shooting equipment is composed of a camera, lens, adapter ring, and light source, and the shooting equipment is fixed at the front end of the production line by a mechanical bracket, and the position where the moving fabric swings is the smallest is selected for shooting to ensure the quality of the captured image and the stability of the output result sex.

[0049] Among them, the German Smartek Gigabit Ethernet industrial camera is selected, the model is GC1291M, the CCD size is 1 / 3", the size of the generated image is 1296×966, the pixel size is 3.75um×3.75um, and the minimum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com