Test system and method for testing field performance of combine harvester

A technology of combine harvester and test system, which is applied in the field of combine harvester field performance test and test system, can solve the problem that the rotational speed and torque of the crankshaft of the vibrating screen and the rotational speed of the fan are individually uncontrollable, the double longitudinal axial flow drum is not included, and the overall Control matching and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

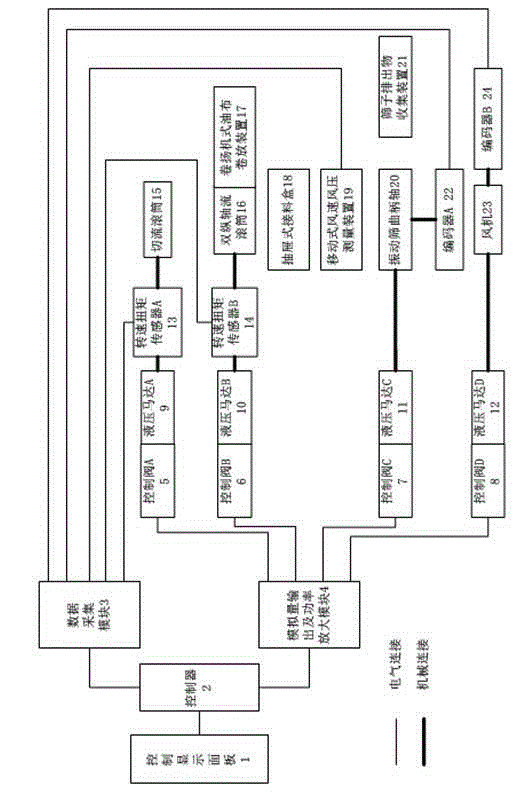

[0021] The field performance test system of the combine harvester of the present invention comprises a header, a conveying device, a threshing system, a granary, an engine, a traveling device, a transmission system, and a manipulation control device. Such as figure 1 As shown, the cutting flow drum 15, the double longitudinal axial flow drum 16, the vibrating screen crank shaft 20 and the fan 23 in the threshing system are respectively powered by the hydraulic motor A9, the hydraulic motor B10, the hydraulic motor C11 and the hydraulic motor D12, and the hydraulic motor A9 , hydraulic motor B10, hydraulic motor C11, and hydraulic motor D12 are respectively connected to control valve A5, control valve B6, control valve C7, and control valve D8, and control valve A5, control valve B6, control valve C7, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com