Novel process for heaping-yellowing and baking of yellow buds

A new technology, dull yellow technology, applied in yellow bud dull yellow and new baking technology field, can solve the problem of lack of luster, and achieve the effect of rich and lasting aroma, good color and rich aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Take an appropriate amount of green tea, and put it into the drying equipment for initial drying until it is 70% dry, (the initial drying temperature is controlled at 110°C) and ferment for 6 hours in the stuffy yellow room, and then dry it until it reaches 8.5% dryness. Place it in the veneering room for 30 hours to carry out secondary veneering (the re-drying temperature is controlled at 100°C), and finally the tea leaves are re-dried and fully fired (the temperature is controlled at 90°C) at an interval of 2-3 hours, and the obtained Bright green color, yellow buds with strong and persistent aroma.

Embodiment 2

[0017] Take an appropriate amount of green tea, put it into the drying equipment and dry it until it is 70% dry, then ferment it in the yellow room for 7 hours, and then dry it to 8.5% dryness. Put it in the stuffy yellowing room for 25 hours to carry out the second stuffy yellowing (the re-drying temperature is controlled at 100°C), and finally the tea leaves are re-dried and fully fired (the temperature is controlled at 90°C) at an interval of 2-3 hours, and the obtained Bright green color, yellow buds with strong and persistent aroma.

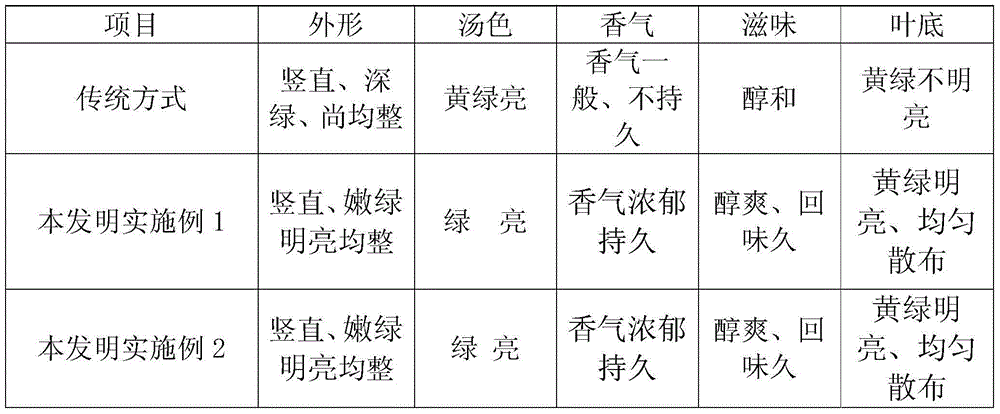

[0018] Through new technology practice and test, now embodiment test result is sorted out as follows:

[0019] Table I

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com