Zheng'an white tea processing method

A technology of Zhengan white tea and its processing method, which is applied in the field of tea processing, can solve the problems of loose shape of tea leaves, damage of free amino acid content, peculiar smell of aroma of finished tea, etc. Tight and fine, fragrant and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

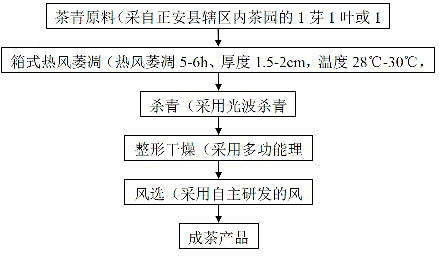

[0018] A processing method of Zheng'an white tea, comprising the steps of:

[0019] (1) Selection of raw materials: In the area under the jurisdiction of Zheng'an County, the tea tree ecological environment is excellent, and the tea garden is at an altitude of 800-1100m. The tea tree variety is Baiye No. 1 clone, and the planting mode is mainly "forest-tea interplanting". Picking in the morning Between 8 and 12 o'clock, and between 2 and 5 o'clock in the afternoon, pick tea green raw materials with 1 bud and 1 leaf or 1 bud and 2 leaves;

[0020] (2) Green tea withering: Wither 80 catties of tea green raw materials picked by the company through a box-type hot air withering machine independently developed by the company. Evenly spread the tea greens in the withering sieve, the hot air withering time is 5-6 hours, the thickness is 1.5cm, the wind speed is controlled at 300 rpm, the temperature in the box is 28°C, and the humidity is 80%. After withering, the tea greens are about...

Embodiment 2

[0025] A processing method of Zheng'an white tea, comprising the steps of:

[0026] (1) Selection of raw materials: In the area under the jurisdiction of Zheng'an County, the tea tree ecological environment is excellent, and the tea garden is at an altitude of 800-1100m. The tea tree variety is Baiye No. 1 clone, and the planting mode is mainly "forest-tea interplanting". Picking in the morning Between 8 and 12 o'clock, and between 2 and 5 o'clock in the afternoon, pick tea green raw materials with 1 bud and 1 leaf or 1 bud and 2 leaves;

[0027] (2) Green tea withering: Wither 90 catties of tea green raw materials picked by the company through a box-type hot air withering machine independently developed by the company. Spread the green tea evenly and thinly in the withering sieve, the hot air withering time is 5.5 hours, the thickness is 1.8cm, the wind speed is controlled at 300 rpm, the temperature in the box is 29°C, and the humidity is 83%. The green tea after withering i...

Embodiment 3

[0032] A processing method of Zheng'an white tea, comprising the steps of:

[0033] (1) Raw material selection: within the jurisdiction of Zheng’an County, there are tea gardens with excellent ecological environment and an altitude of 800-1100m. The tea tree variety is Zheng’an white tea tea element variety, and the planting mode is mainly "forest-tea interplanting". Between 12 o'clock and between 2-5 o'clock in the afternoon, pick green tea raw materials with 1 bud and 1 leaf or 1 bud and 2 leaves;

[0034] (2) Green tea withering: Wither 100 catties of green tea raw materials picked by the company through a box-type hot air withering machine independently developed by the company. Evenly spread the green tea in the withering sieve, the hot air withering time is 6 hours, the thickness is 2cm, the wind speed is controlled at 300 rpm, the temperature in the box is 30°C, and the humidity is 85%. The green tea after withering is about 75 catties, so that the leaves It is suitable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com