Vermicelli automatic packaging machine bag device

An automatic packaging machine and packaging bag technology, applied in packaging and other directions, can solve the problems of easy winding of vermicelli, difficulty in automatic bagging, and difficulty in sliding, so as to reduce the difficulty and simplify the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

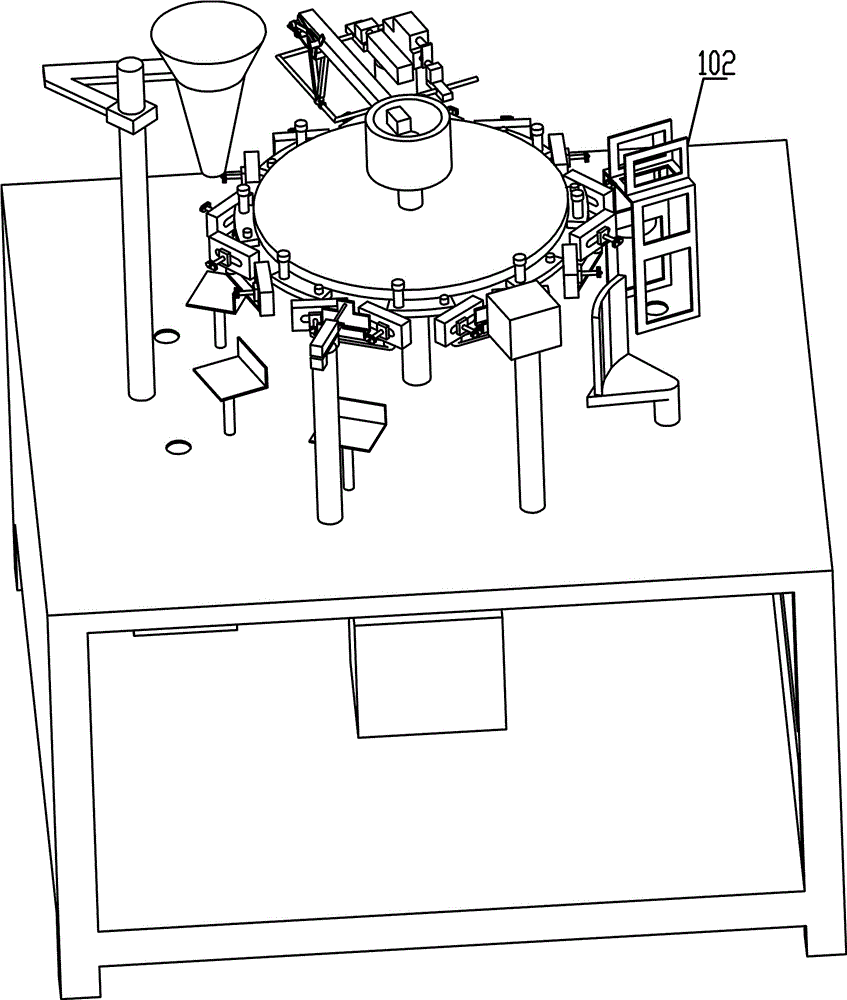

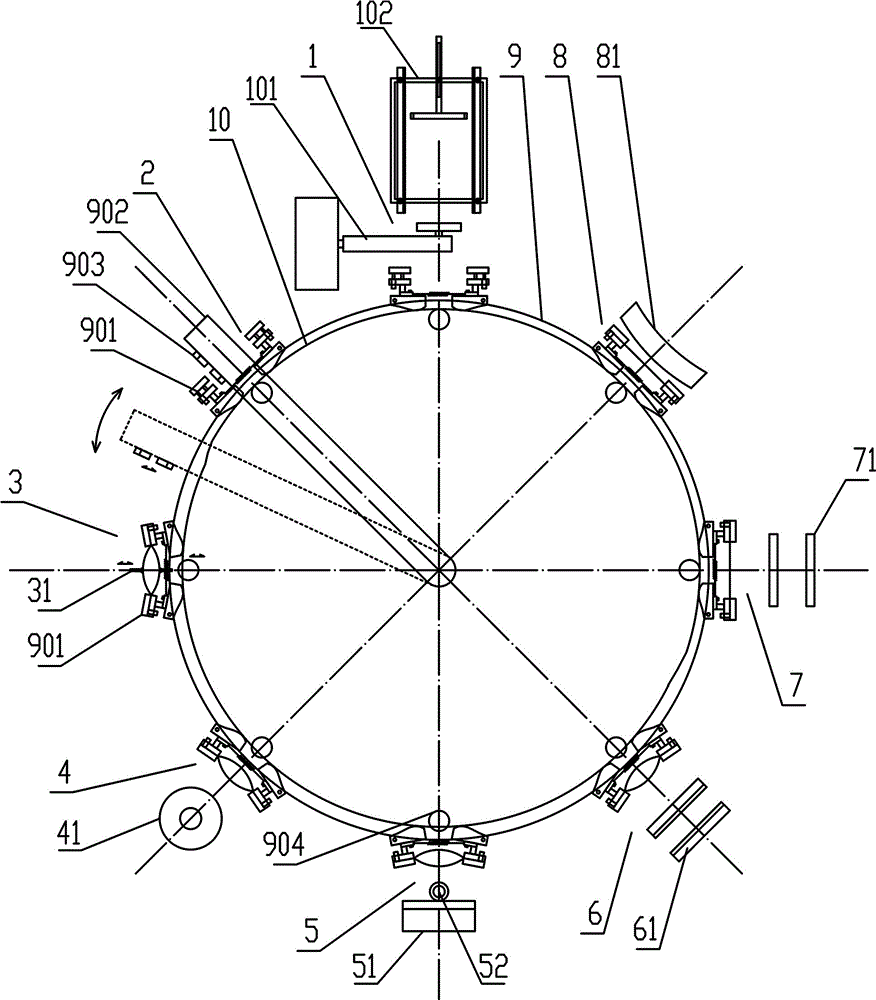

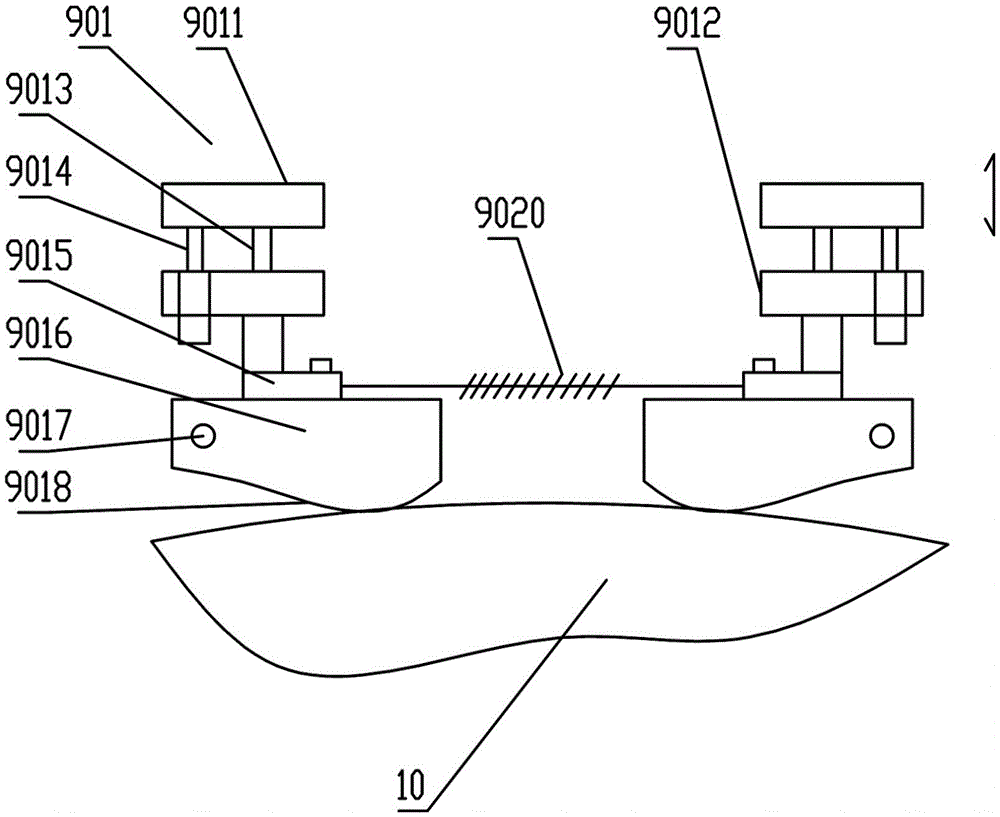

[0032] Such as figure 1 , 2 , 7, 8, a bagging device for vermicelli automatic packaging machine, including a bag storage rack 102, a bag taking mechanical arm 101 and a bag clamping device 901, a liftable suction cup frame 103 is provided below the bag storage frame 102, and the suction cup frame The top of 103 is provided with a plurality of vacuum suction cups 1031;

[0033] The bag-taking robot arm 101 is arranged between the bag-clamping device 901 and the suction cup frame 103, and an openable bag-taking clip is provided at the end of the bag-taking robot arm 101 for clamping the packaging bag 11 to the bag-clamping device 901 superior. With this structure, the packaging bag in the bag storage rack 102 is automatically clamped to the bag clamping device 901 to package the vermicelli.

[0034] Such as figure 2 , 7 , 8, in the bag storage rack 102, the bag storage rack side panels 1021 with adjustable relative spacing are installed on both sides of the bag storage rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com