Buffer bracket for bucket wheel machine cab

A cab and bucket wheel machine technology, which is applied in the field of buffer brackets for bucket wheel machine cabs, can solve the problems of easy wear of the steering shaft, unstable support parts, and falling off of the cab, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

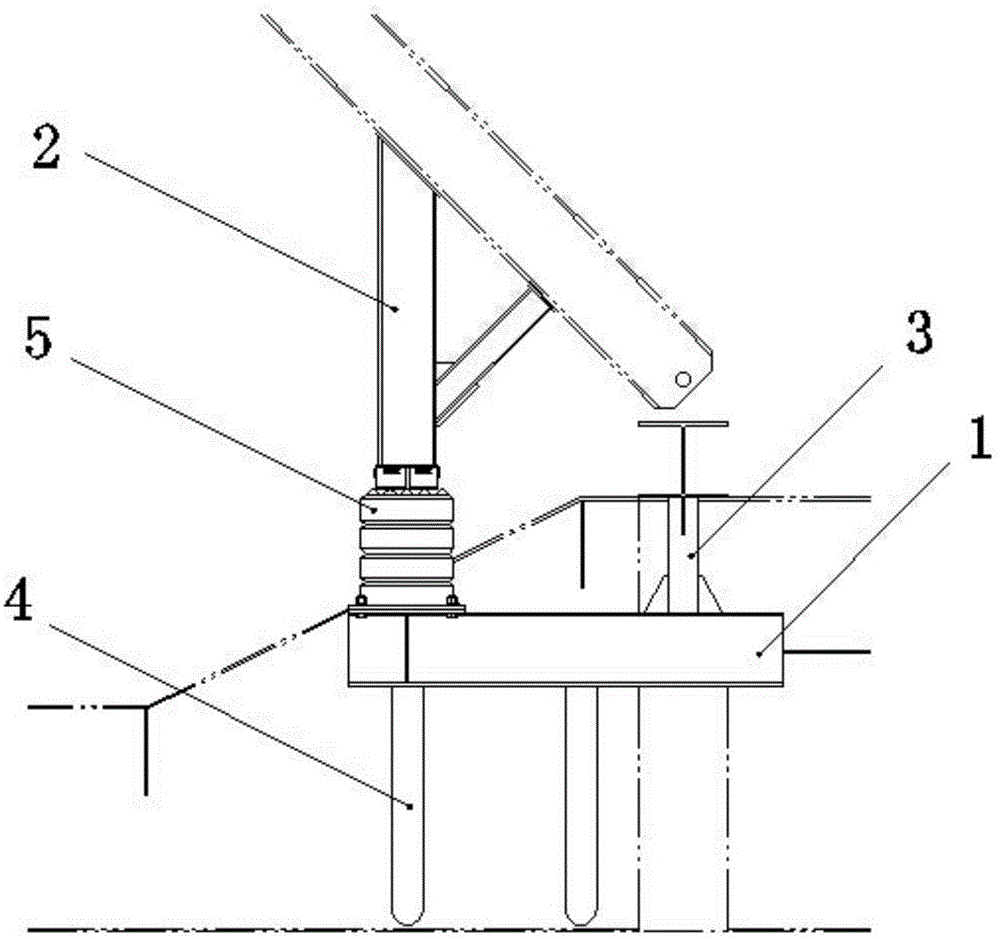

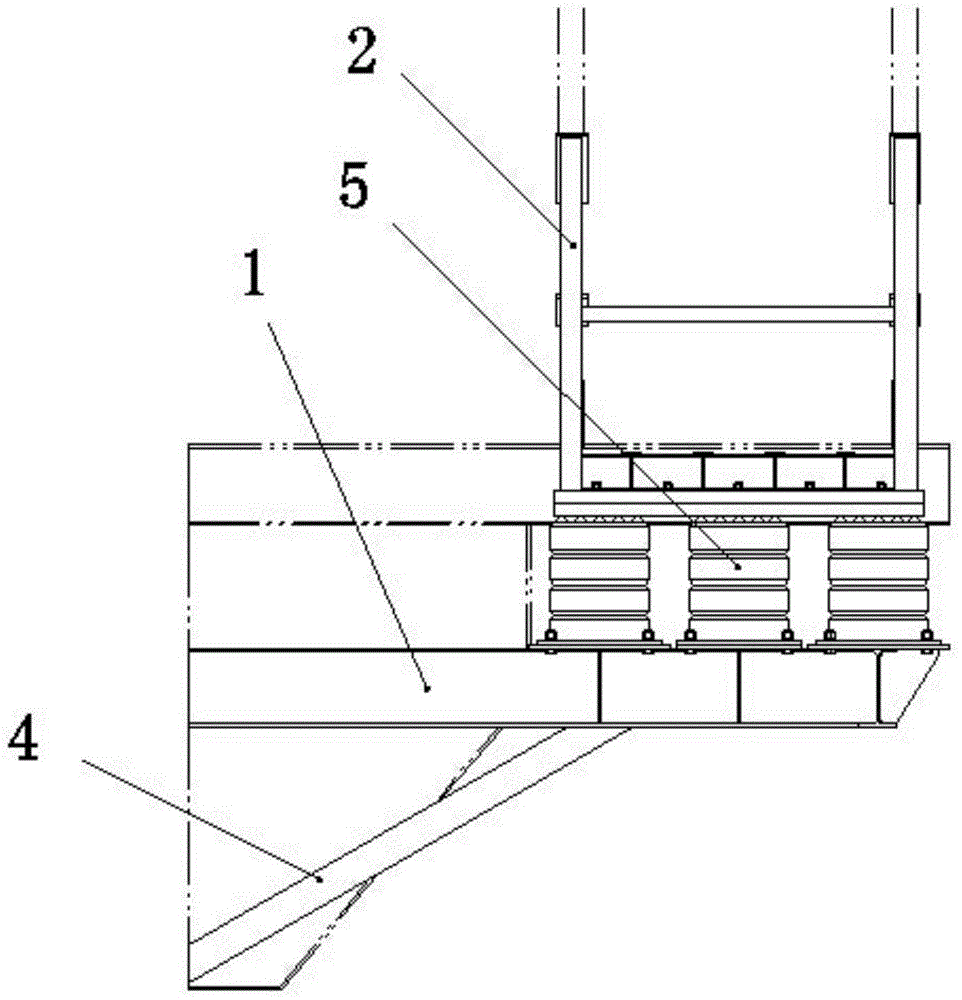

[0014] as attached Figure 1-2 As shown, a buffer bracket for a bucket wheel machine cab according to the present invention includes a platform frame 1 and a door frame 2; the platform frame 1 is provided with a boom 3, and the lower side of the platform frame 1 is provided with a support pipe 4. The door frame 2 is arranged on the upper side of the platform frame 1; the platform frame 1 is provided with a buffer device 5 at a position corresponding to the door frame 2; the buffer device 5 can be provided with multiple, multiple buffer devices 5 lined up, correspondingly arranged on the lower side of the door frame 2.

[0015] Because the platform frame 1 is equipped with a buffer device 5 at the position corresponding to the door frame 2, when the steering shaft of the bucket wheel machine cab is worn and broken, the door frame 2 of the cab will fall on the buffer device 5, which redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com