Caprolactam sewage advanced treatment method using ozone catalytic oxidation

A technology of ozone catalytic oxidation and caprolactam, which is applied in the field of advanced treatment of caprolactam sewage, can solve problems such as high operating costs, limited biochemical process effects, and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

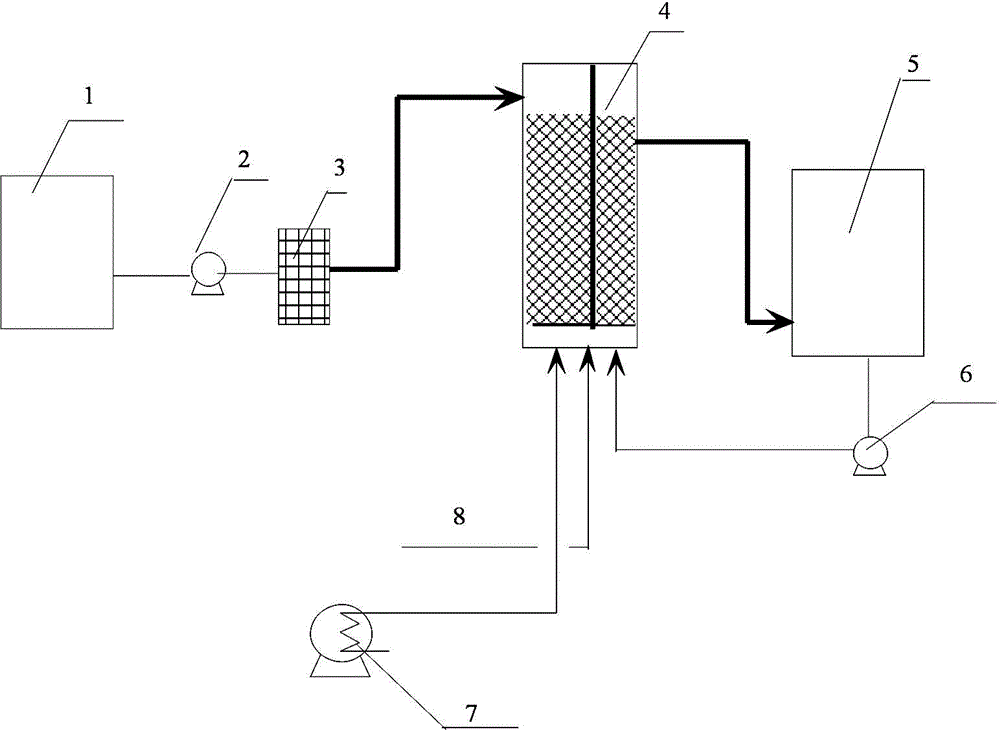

[0014] Implementation Example 1: Application of ozone catalytic oxidation to advanced treatment of caprolactam sewage using figure 1 The process flow shown is for advanced treatment of the caprolactam sewage, and the specific implementation steps are as follows:

[0015] ①, the pretreated caprolactam sewage (water quality analysis data is shown in Table 1) is lifted into the filter 3 by the water inlet lifting pump 2;

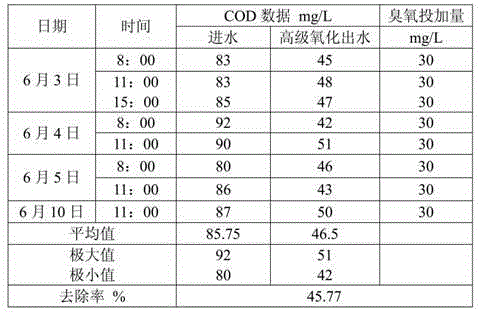

[0016] ②. The water from the filter 3 flows into the ozone catalytic oxidation tank 4 (the ozone catalyst is Cu / TiO 2 / Al 2 o 3 , model: KH-SC-XT, manufacturer: Suzhou Kehuan Environmental Protection Technology Co., Ltd.), at the same time, add ozonated air with a concentration of 100mg / L to the ozone catalytic oxidation tank 4, and the ozone dosage is 30mg / L sewage, The oxidation residence time is 2h, and the ozone catalytic oxidation reaction is carried out;

[0017] ③. The oxidized effluent flows into the clear water pool 5 by itself, and the clear water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com