A kind of Belite cement and preparation method thereof

A Belite and cement technology, applied in the direction of cement production, etc., can solve the problems of increased water absorption of concrete, sanding on the concrete surface, and shrinkage of strength, so as to save resources and energy, enhance hydration activity, and enhance early strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

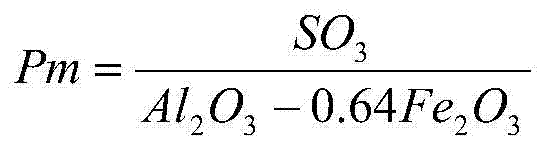

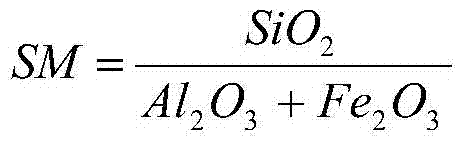

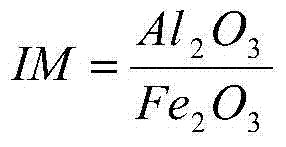

[0046] Limestone, clay, aluminum ore waste rock and desulfurized gypsum were used as raw materials (see Table 1 for chemical composition). According to the rate value and mineral composition of the cement clinker designed in Table 2, the chemical composition of the clinker is calculated, and then the batching method is used for batching. The result of the batching is in parts by weight, 73.5 parts of limestone, 18.5 parts of clay, aluminum 6 parts of mine waste rock, 2 parts of desulfurization gypsum. Put these raw materials together into an experimental ball mill and grind until no more than 10% of the raw meal powder is sieved through an 80 μm square hole sieve. Add a small amount of water to the raw meal powder and stir it evenly, then press it into a raw meal cake. After drying, preheat it in a muffle furnace at 950°C for 30 minutes, and then move it into a high-temperature electric furnace at 1380°C for calcination for 60 minutes. After the calcination is finished, take ...

Embodiment 2

[0056] Limestone, clay, aluminum ore waste rock and desulfurized gypsum were used as raw materials (see Table 1 for chemical composition). Calculate the chemical composition of the clinker according to the rate value and mineral composition of the cement clinker designed in Table 4, and then use the trial mix method to batch the ingredients. The results of the ingredients are in parts by weight: 71 parts of limestone, 18 parts of clay, aluminum 8 parts of mine waste rock, 2 parts of desulfurization gypsum. These raw materials are put into an experimental ball mill and ground until 8% to 10% of the raw meal powder is sieved through an 80 μm square hole sieve. Add a small amount of water to the raw meal powder and stir evenly, then press it into a raw meal cake. After drying, preheat it in a muffle furnace at 950°C for 30 minutes, and then move it into a high-temperature electric furnace at 1360°C for calcination for 60 minutes. After the calcination is finished, take it out an...

Embodiment 3

[0063] Limestone, quartz sand, fly ash, steel slag and desulfurized gypsum were used as raw materials (see Table 6 for chemical composition). Calculate the chemical composition of the clinker according to the rate value and the mineral composition of the cement clinker designed in Table 7, and then use the trial mix method to batch the ingredients. The results of the ingredients are in parts by weight, 74.5 parts of limestone, 7 parts of quartz sand, 8 parts of fly ash, 8.5 parts of steel slag, and 2 parts of desulfurized gypsum. These raw materials are put into a raw meal mill and ground until no more than 15% of the raw meal powder is sieved through an 80 μm square hole sieve. The raw meal powder is fed into the preheater through the bucket elevator, and enters the calciner after five-stage preheating, and then enters the rotary kiln for calcination. The decomposition rate of the raw meal in the kiln is about 96%. The raw material is calcined in a rotary kiln for 30-40 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com