Continuous layered fracturing ball injector and control method thereof

A technology of layered fracturing and ball-throwing device, which is applied in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of long blocking ball throwing time, affecting work efficiency, high-pressure risk, etc., and reducing throwing time, improve work efficiency, and reduce the risk of high-pressure shot blocking the effect of the ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

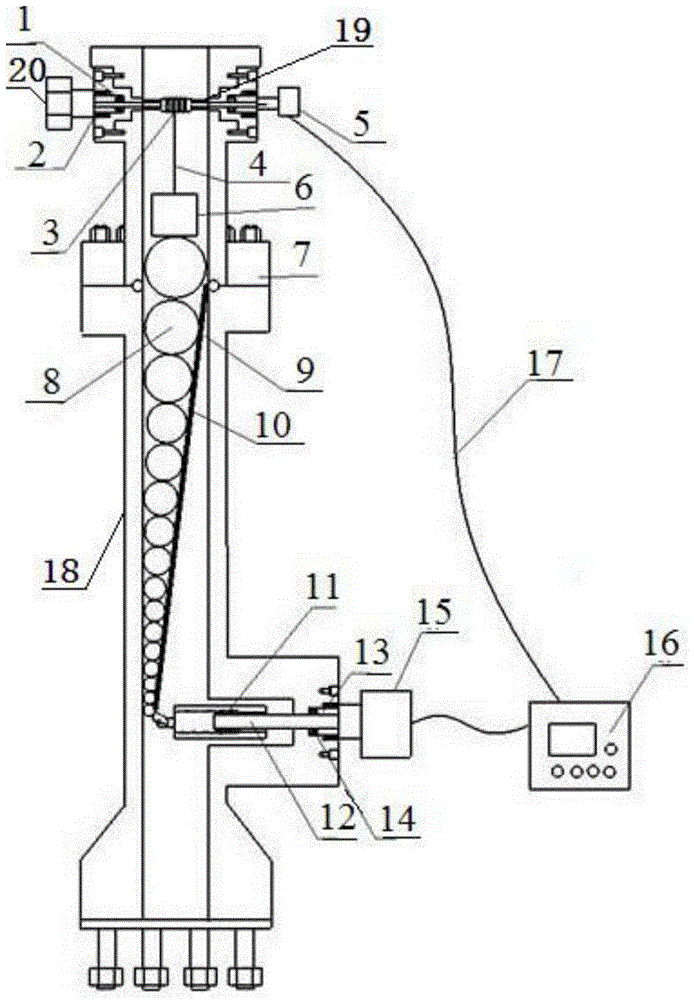

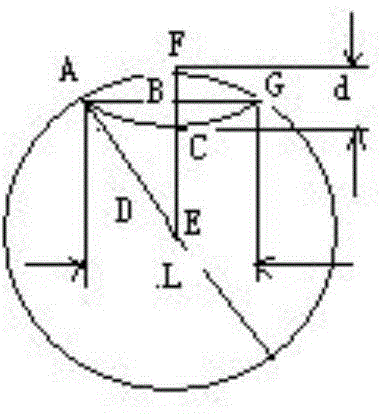

[0032] In order to overcome the problems that the operator faces high pressure risk and takes a long time to throw the ball during the existing continuous layer fracturing construction process, which affects the work efficiency, this embodiment provides a method such as figure 1 The continuous layered fracturing ball pitcher shown includes a casing 18, a high-pressure ball storage cylinder 9 is arranged inside the casing 18, and an arc-shaped volleyball plate 10 is obliquely arranged in the inner cavity of the high-pressure ball storage cylinder 9. In the space formed between the upper surface of the arc-shaped volleyball board 10 and the wall of the high-pressure ball storage cylinder 9, a plurality of plugging balls 8 whose diameters gradually increase are stacked from bottom to top, and the lower end of the arc-shaped volleyball board 10 is connected with the high-pressure storage ball A feeding port is formed between the cylinder walls of the cylinder 9, and a reciprocating...

Embodiment 2

[0037] On the basis of embodiment 1, in order to operate conveniently, described remote controller 16 comprises PLC controller, power supply and operation box panel; Described operation box panel is provided with display screen, power switch, throws and blocks the ball button, Indicator light, reset switch and safety switch; in this way, the operator can operate from a long distance without getting close to the pitcher, which realizes safe production.

[0038] The steel wire 4 is a 1.0mm stainless steel wire.

[0039] A sealing ring 1 is provided between the roller shaft 19 and the first thrust bearing 2 ; a sealing ring 2 14 is provided between the rotating rod 12 and the second thrust bearing 13 .

[0040] The diameters of the stacked plurality of plugging balls 8 form an arithmetic sequence from bottom to top, and the diameters of the plugging balls 8 thrown can be any one or several of the arithmetic sequence during use.

[0041] In this embodiment, the number of plugging b...

Embodiment 3

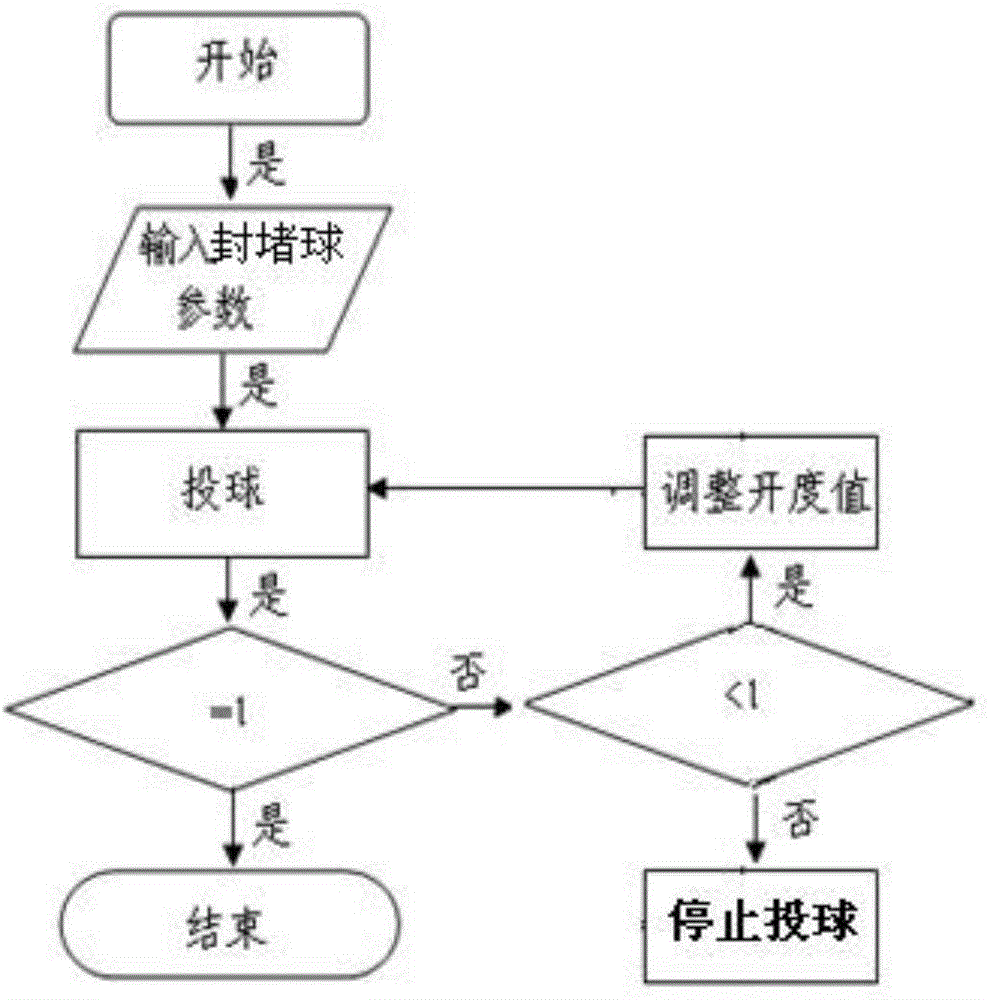

[0053] On the basis of Embodiment 1, this embodiment provides a method for controlling a continuous layered fracturing ball launcher, including the following steps:

[0054] 1) The remote controller 16 controls the rotation of the stepper motor 15 to drive the reciprocating rod 11 to move, so that the size of the opening formed between the lower end of the arc-shaped volleyball plate 10 and the wall of the high-pressure ball storage cylinder 9 reaches the minimum position, that is, the initial position;

[0055] 2) The plugging balls 8 to be put into the well are loaded into the high-pressure ball storage cylinder 9 in the order of diameter from small to large;

[0056] 3) store the diameter of each blocking ball 8 in the remote controller 16;

[0057] 4) Hoist the assembled continuous layered fracturing ball launcher on the top of the wellhead, and connect it to the wellhead through the flange 7;

[0058] 5) start throwing blocking ball; Remote controller 16 controls stepper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com