Parcel delivery method, parcel delivery control device and parcel delivery equipment

A delivery method and package technology, applied in instruments, sorting and other directions, can solve the problems of low efficiency, inability to guarantee robots to deliver packages, slow delivery speed, etc., to save delivery time, improve delivery efficiency, and eliminate braking and The effect of restart time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

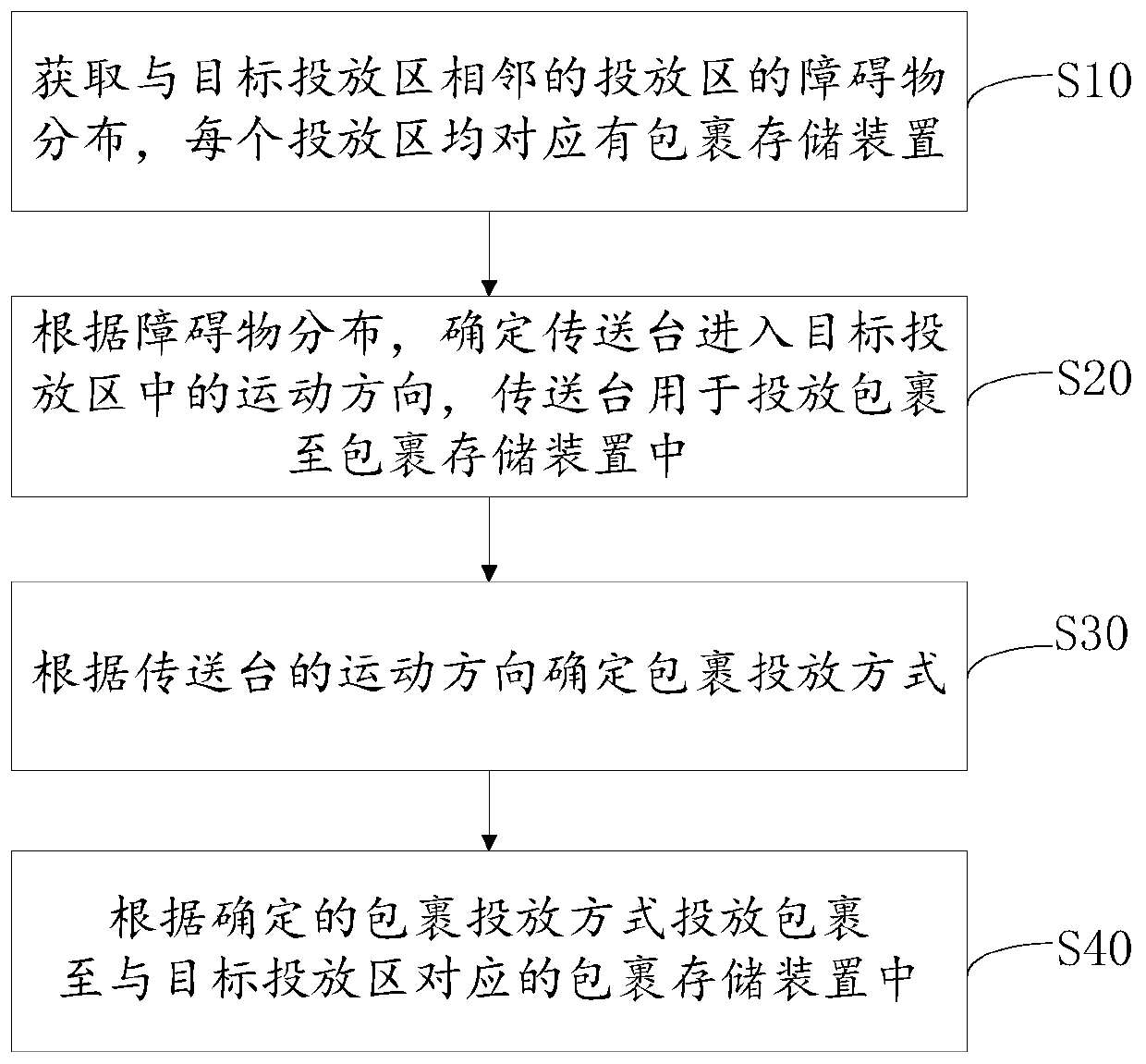

[0075] In a specific embodiment, such as figure 1 As shown, a package delivery method is provided, including:

[0076] Step S10: Obtain the obstacle distribution of the drop-in area adjacent to the target drop-in area, each drop-in area corresponds to a package storage device;

[0077] Step S20: According to the distribution of obstacles, determine the direction of movement of the transfer table into the target delivery area, and the transfer table is used to drop packages into the package storage device;

[0078] Step S30: Determine the delivery mode of the parcel according to the moving direction of the conveyor table;

[0079] Step S40: according to the determined package delivery method, deliver the package to the package storage device corresponding to the target delivery area.

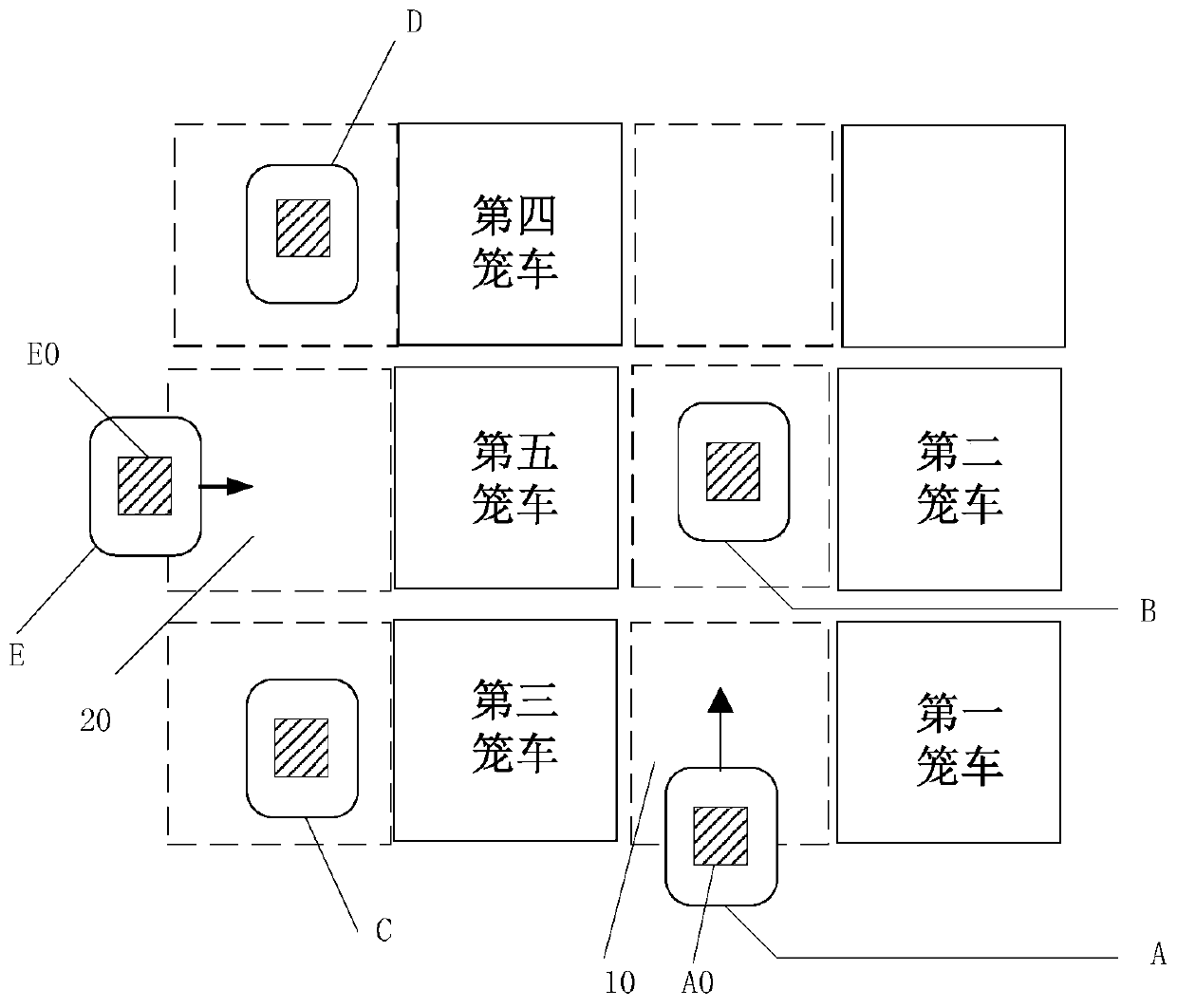

[0080] In one example, multiple parcel storage devices are arranged vertically in multiple rows, and multiple drop-in areas are set between two adjacent rows of package storage devices, and eac...

Embodiment 2

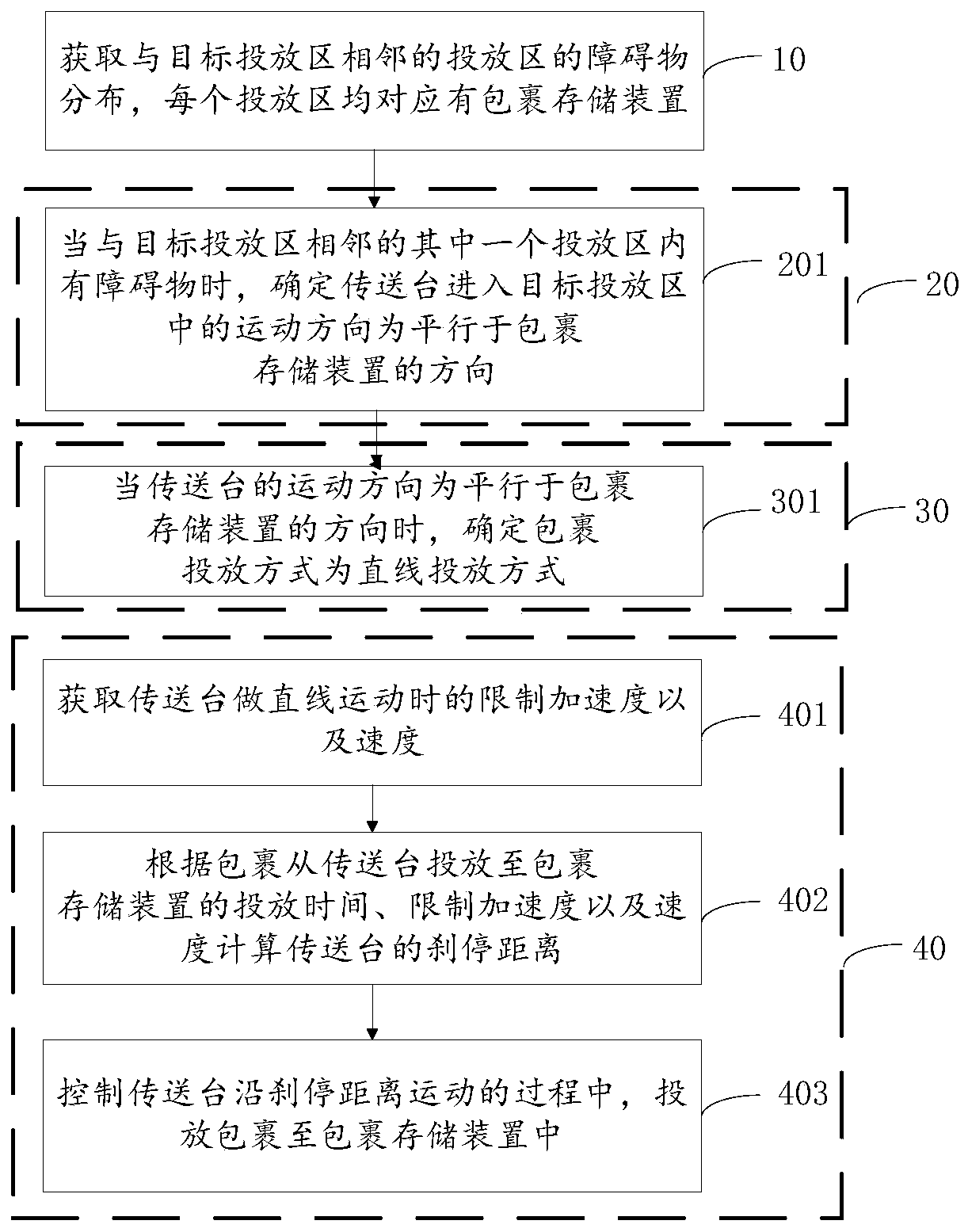

[0113] This embodiment provides a package delivery control device, such as Figure 9 As shown, the package release control device includes:

[0114] The obstacle detection module 10 is used to obtain the obstacle distribution of the drop-in area adjacent to the target drop-in area, and each drop-in area corresponds to a parcel storage device;

[0115] The direction of motion determination module 20 is used to determine the direction of motion of the transport platform into the target drop-in area according to the distribution of obstacles;

[0116] Parcel delivery mode determination module 30, used to determine the parcel delivery mode according to the direction of motion of the transfer platform;

[0117] The package delivery module 40 is configured to deliver packages to the package storage device corresponding to the target delivery area according to the determined package delivery method.

[0118] The structure of the package delivery control device includes a processor ...

Embodiment 3

[0142] In one example, a package delivery device is also provided, such as Figure 12 As shown, the package delivery equipment includes a moving base 1, a column 2 and a transmission platform 3. The upper and lower ends of the column 2 are respectively connected to the transmission platform 3 and the movement base 1. The package delivery control device 4 may be a chip, which is installed on the upper surface. Wherein, the moving base 1 is used for carrying the conveying platform 3 to move. The moving base 1 includes a driving wheel 11 and a driven wheel 12. The driving wheel is used to provide the power for the trolley to move, and the driven wheel is used to support the chassis parallel to the ground. The moving base 1 may be an AGV trolley (Automated Guided Vehicle). The transfer table 3 includes a belt pulley 31 and a belt motor 32, and when the package enters the belt pulley 31, the package can be adjusted to the middle delivery position by moving the belt. There are thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com