A coal mine self-moving equipment train moving along the channel

A technology of self-moving equipment trains and troughs, which is used in earth-moving drilling, transportation and packaging, underground transportation, etc., can solve problems such as inability to lift equipment, inability to walk, and low efficiency, and avoid frequent track laying and frequent traction and transportation. Work, improve efficiency and safety, reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

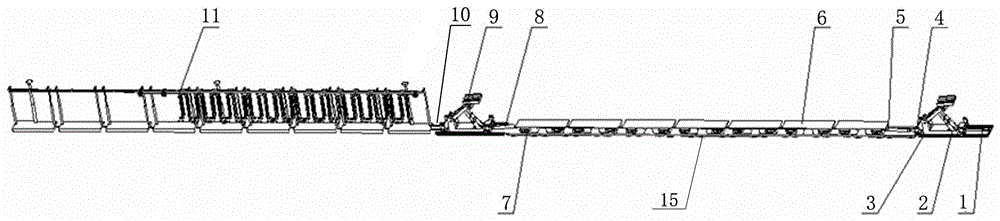

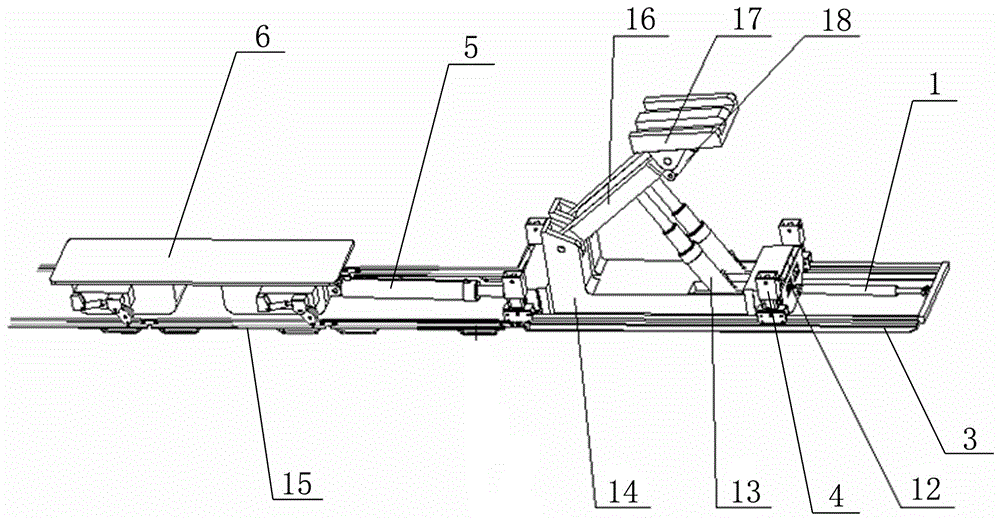

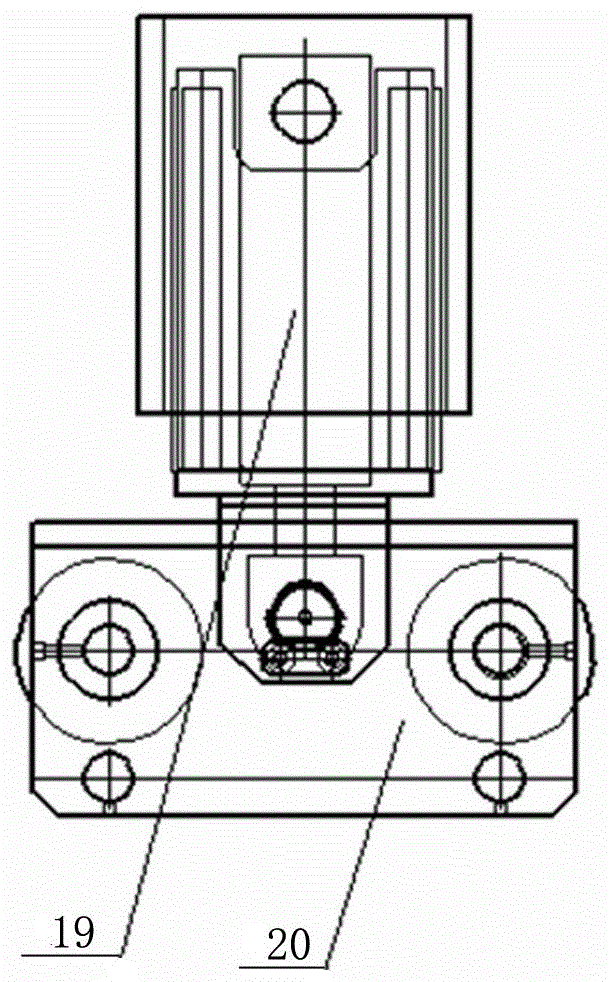

[0032] like figure 1 As shown, a coal mine stepping self-moving equipment train includes a front pushing jack 1, a front anchor pulling device 2, a rear anchor pulling device 9, an anchor frame guide rail 3, a rear pushing jack 5, a flatbed truck 6, and a flatbed truck lifting device 7. Flatbed truck guide rail 15, flatbed truck pushing jack 8, connecting rod 10 and pipe cable telescopic bearing system 11, the front anchor pulling device 2 and rear anchor pulling device 9 are erected on the anchor frame guide rail 3, and the flatbed truck 6 is lifted by the flatbed truck The device 7 is erected on the flatbed truck guide rail 15, and two adjacent flatbed trucks 6 are connected by universal cross joints to adapt to the working conditions of the large slope roadway. The two ends of the flatbed truck guide rail 15 are respectively hinged with the anchor frame guide rail 3. The front end of the front anchor pulling device 2 is provided with a forward pushing jack 1, and the forwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com