Rotor swing system

A rotor, pivoting technology, used in containers, workbenches, supporting machines, etc., can solve problems such as limiting the applicability of rotor pivoting systems, and achieve good load distribution, flexible use, and improved stability and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

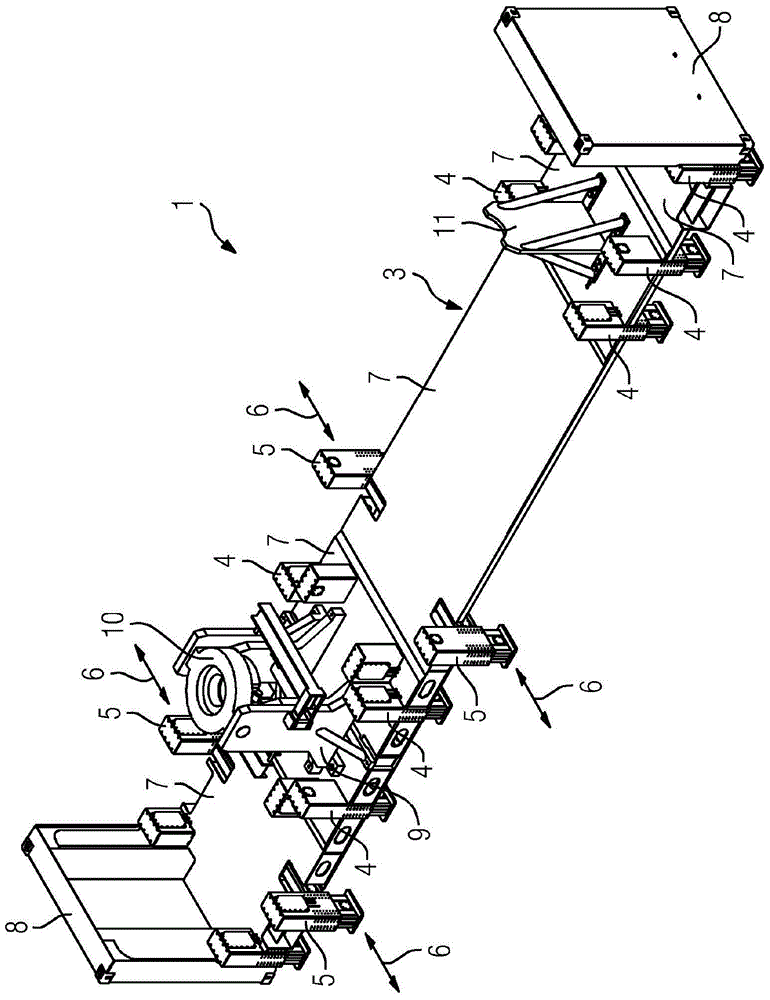

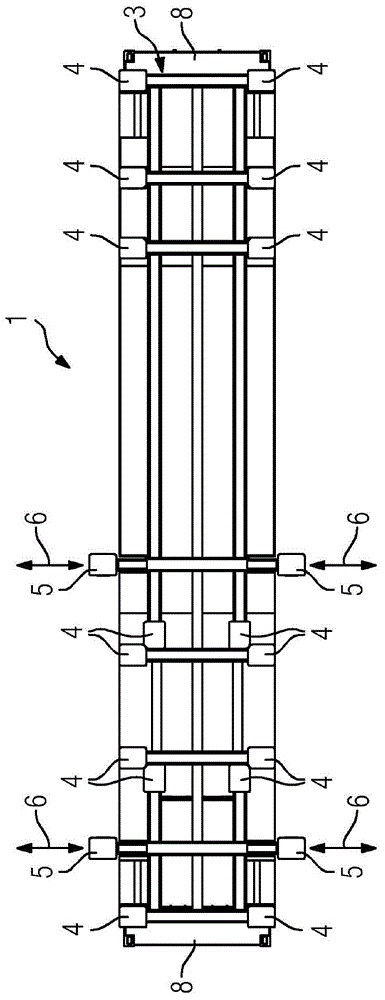

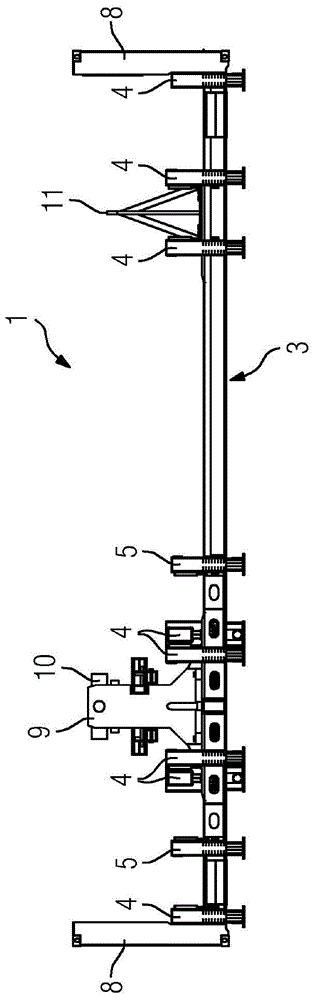

[0031] The figures show a rotor pivot system 1 according to an embodiment of the invention for erecting a rotor, for example for erecting a gas turbine rotor 2 . The rotor pivoting system 1 comprises a heavy-duty frame 3 provided with a plurality of supporting feet 4 and 5 which can be moved out vertically, respectively. The support feet 5 can also be moved out horizontally in the direction of the arrow 6 in order to improve the durability of the heavy duty frame 3 if required. The actuation of the support feet 4 and 5 is currently performed hydraulically, wherein of course alternative actuation variants are also conceivable. On a heavy-duty frame 3 , which can be formed, for example, as a steel frame, a plurality of base plates 7 are held, which define a walkable surface. On its end sides, the heavy-duty frame is provided with an end wall 8 whose dimensions are chosen such that it essentially corresponds to the end wall of a standard container, the current ISO 49' container,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com