a diaphragm pump

A diaphragm pump and diaphragm technology, which is applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of diaphragm pump efficiency loss, low diaphragm life, slow valve response, etc., to reduce air flow fluctuations and improve stability Improvement of performance and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

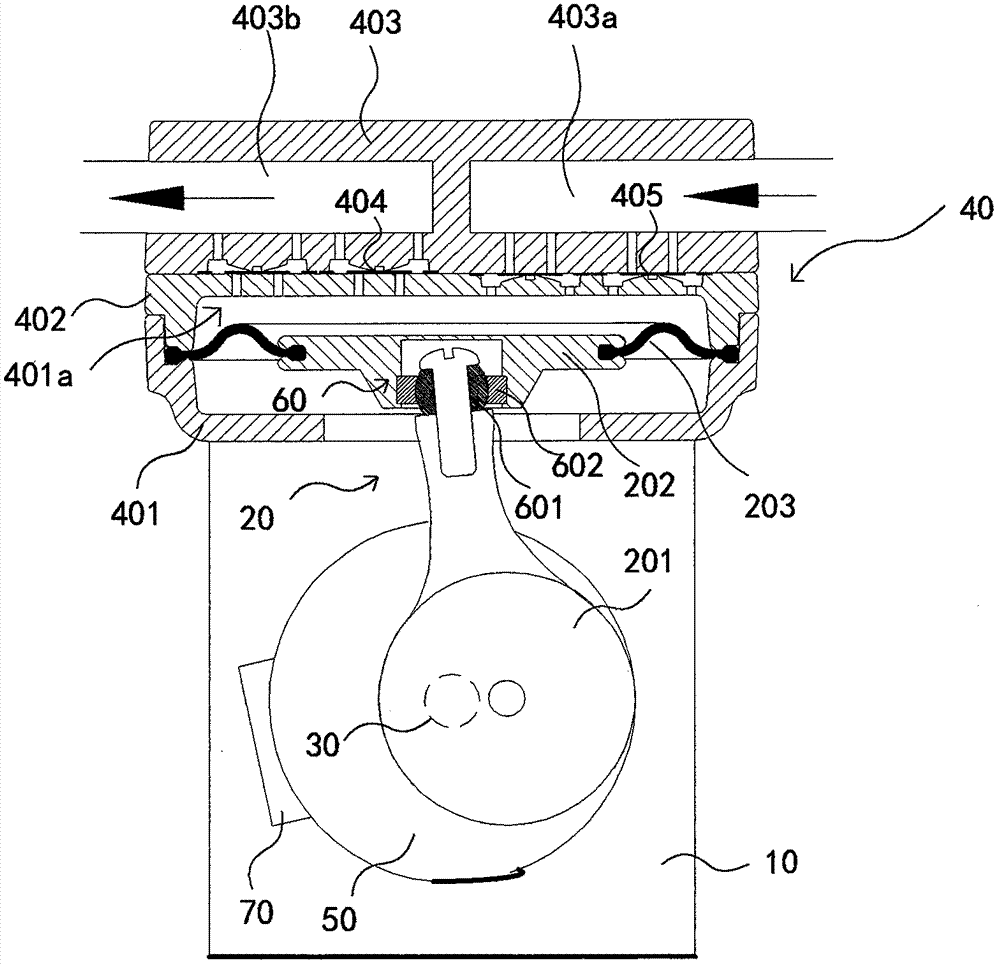

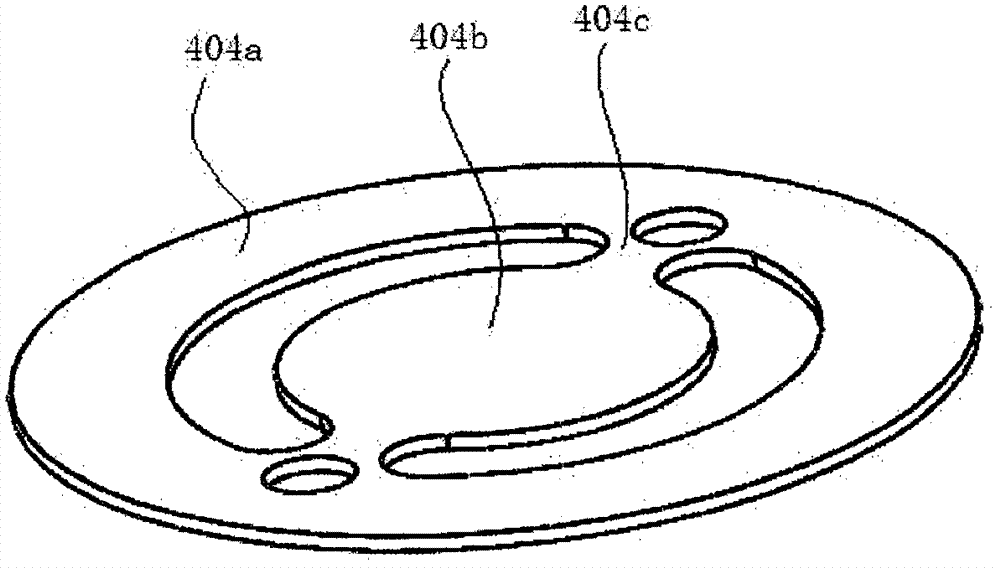

[0019] Embodiment one, this embodiment proposes a kind of diaphragm pump, such as figure 1 As shown, it includes a casing 10, a diaphragm pumping structural assembly 20 arranged in the casing 10, a motor for driving the diaphragm pumping structural assembly, and a pump head assembly 40 arranged at one end of the casing 10, the An eccentric wheel 50 is fixedly arranged on the output shaft 30 of the motor, and the diaphragm suction structure assembly 20 includes a connecting rod 201 eccentrically connected with the eccentric wheel 50, a joint bearing 60 connected with the connecting rod 201, and a joint bearing 60. The connected circular pressing piece 202 and the annular diaphragm 203, the inner ring edge of the diaphragm 203 is pressed and fixed by the pressing piece 202, the outer ring edge is fixed with the pump head assembly 40, and the pump head The assembly 40 includes a pump head seat 401, a valve seat 402 arranged on the upper surface of the pump head seat 401, and a pu...

Embodiment 2

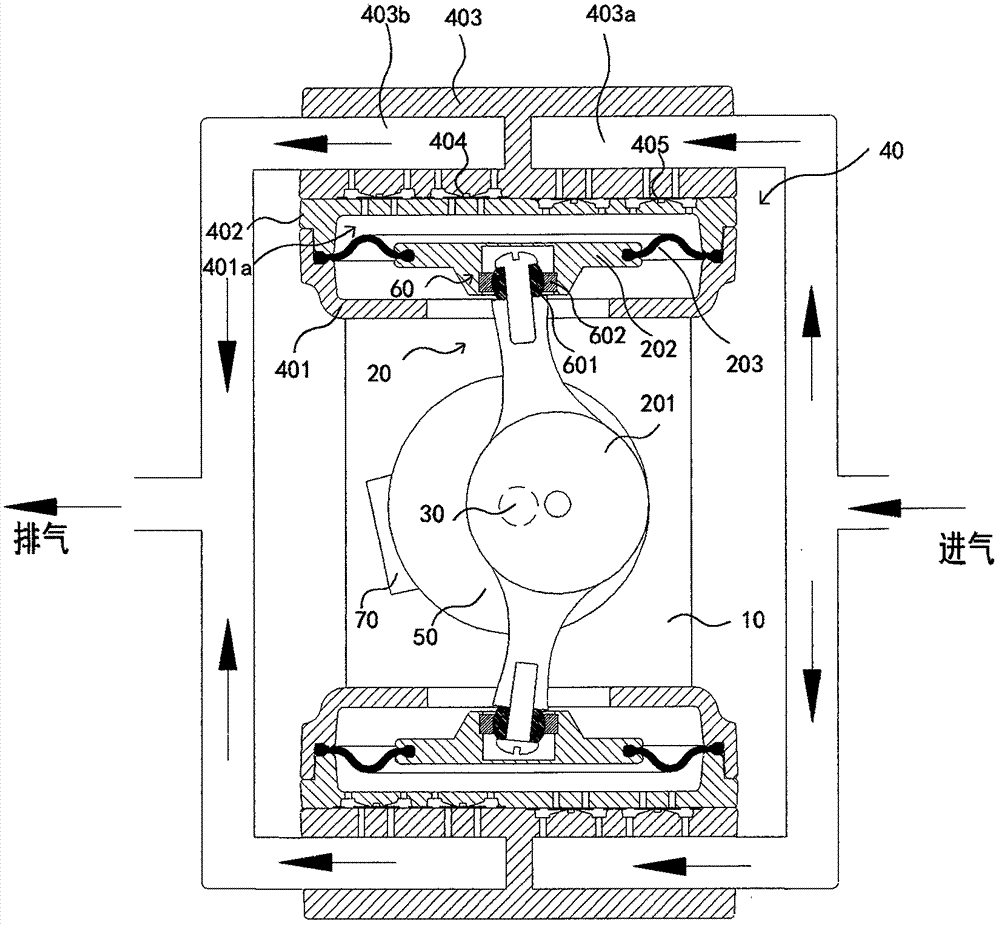

[0026] Embodiment 2, based on a kind of diaphragm pump in embodiment 1, this embodiment proposes another kind of diaphragm pump, this diaphragm pump is a double-headed pump, such as image 3 As shown, it includes a casing 10, a motor output shaft 30, a diaphragm suction structure assembly 20 symmetrically arranged in the casing, pump head assemblies 40 respectively arranged at both ends of the casing 10, and the output shaft of the motor 30 An eccentric wheel 50 is fixedly arranged on the top, taking the diaphragm pumping structural assembly 20 on one side as an example, the diaphragm pumping structural assembly 20 includes a connecting rod 201 connected eccentrically to the eccentric wheel, connected to the connecting rod 201 The joint bearing 60, the circular pressing piece 202 connected with the joint bearing 60, and the annular diaphragm 203, the inner ring edge of the diaphragm 203 is pressed and fixed by the pressing piece 202, and the outer ring edge and the diaphragm T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com