An axial flow pump impeller guide cone

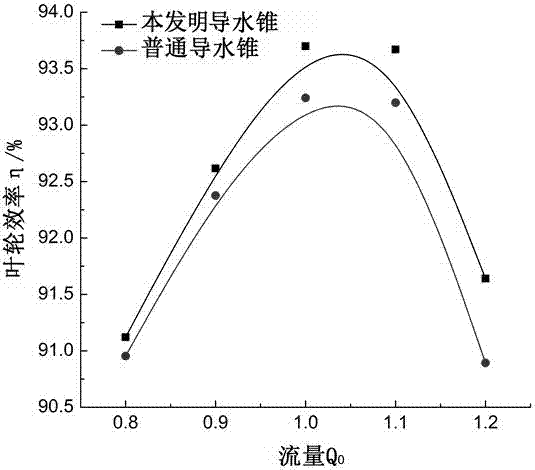

A water guide cone and axial flow pump technology, which is applied to pumps, parts of pumping devices for elastic fluids, pump elements, etc., can solve the problems of no pre-rotation, etc., and achieve the goal of improving speed uniformity and improving impeller efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

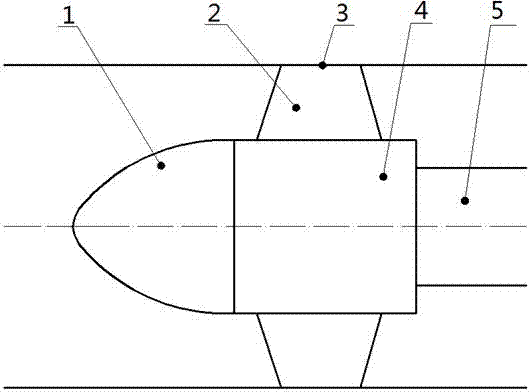

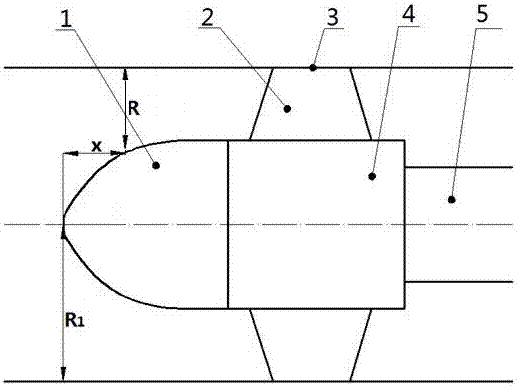

[0023] figure 1 A sectional view of the axial flow guide cone of the impeller of the axial flow pump of the present invention is given, figure 2 The axial sectional view of the water guide cone of the impeller of an ordinary axial flow pump is given.

[0024] Depend on figure 1 , 2 It can be seen that both the water guiding cone of the impeller of the present invention and the traditional water guiding cone of the impeller include the water guiding cone 1, the hub body of the impeller 4, the axial flow blades 2 evenly arranged on the circumference of the hub body, the wall surface of the impeller chamber 3, and the pump shaft 5.

[0025] Take the length L of the water guide cone: L is taken as (0.5~1.0)d h , d h is the diameter of the impeller hub.

[0026] Starting from the head of the water guide cone, calculate the R value corresponding to each x according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com