Sine crank mechanism of preloaded bearing

A crank mechanism and preload bearing technology, applied in mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of noise, wear, low noise output accuracy, etc., and achieve reduced impact, low cost, and noise reduction. and wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

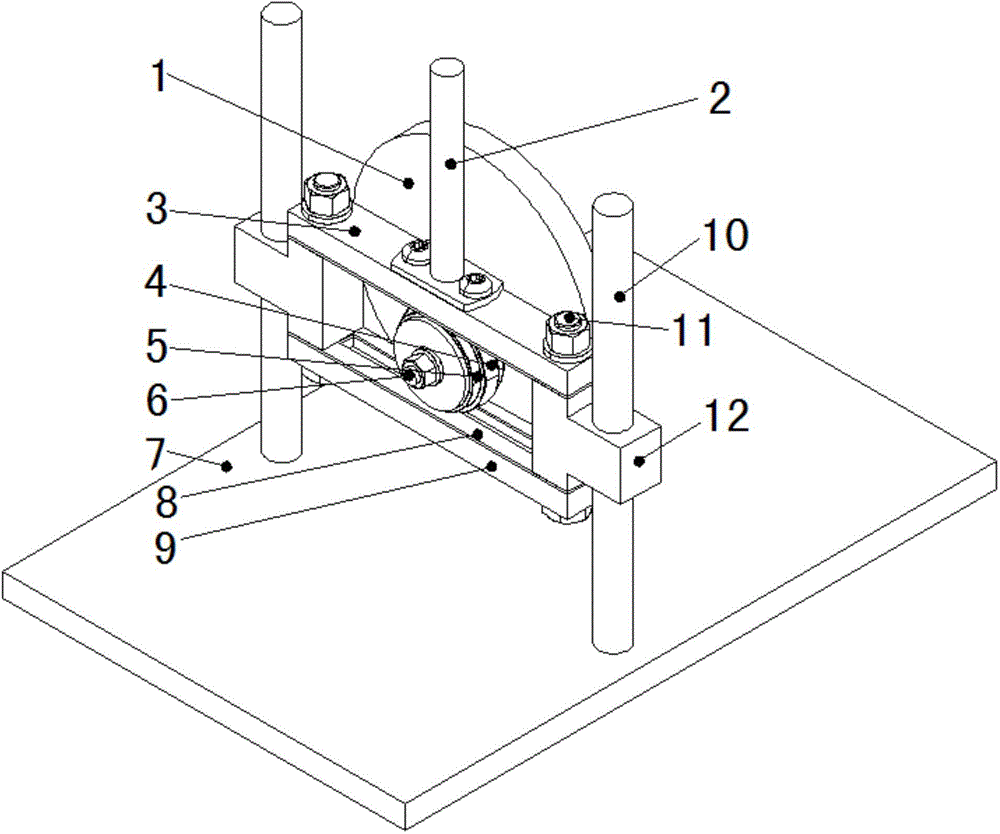

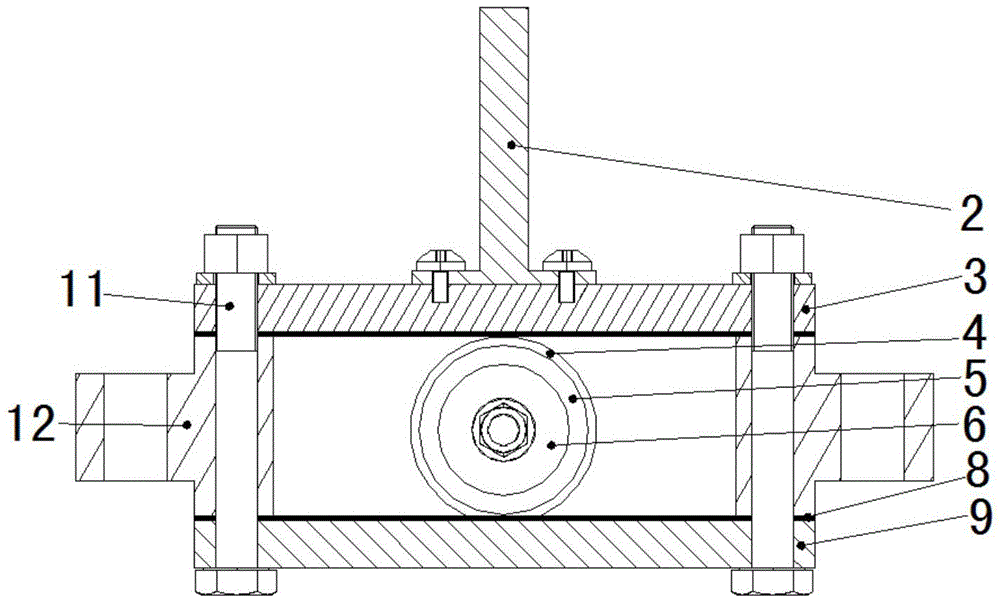

[0014] Such as figure 1 As shown, a preloaded bearing sinusoidal crank mechanism includes a drive turntable 1, an output connecting rod 2, a frame upper cover 3, a first bearing 4, a second bearing 5, a crank cantilever 6, a frame lower cover 9, and a guide rail 10 , the connector 12 and the base 7, the first bearing 4 and the second bearing 5 are coaxially installed on the crank cantilever 6, the crank cantilever 6 is fixed to the drive turntable 1 by a nut, and the frame is composed of the upper cover plate 3 of the frame and the lower frame of the frame. The cover plate 9 is fixed to the connecting piece 12 by two bolts 11, the frame is slidingly connected with the guide rail 10 through the connecting piece 12, the output link 2 is fixed on the upper cover plate 3 of the frame, and the guide rail 10 is fixed on the base 7.

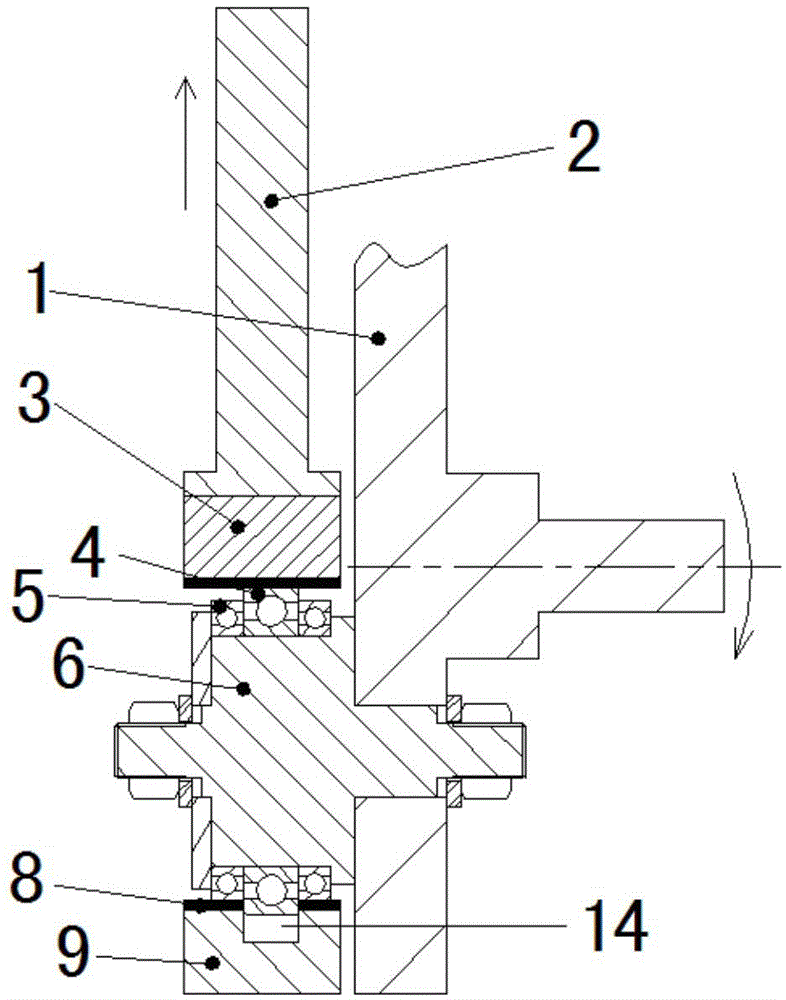

[0015] Such as figure 2 As shown: the upper end face of the first bearing 4 is in contact with the inner surface of the upper cover plate 3 of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com