Multifunctional heat recovery heat exchanger and running method thereof

A technology of heat exchanger and heat recovery, which is applied in the field of multi-functional heat recovery heat exchanger, can solve problems such as inability to adjust, and achieve the effects of simple control, reduced air conditioning load, and large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

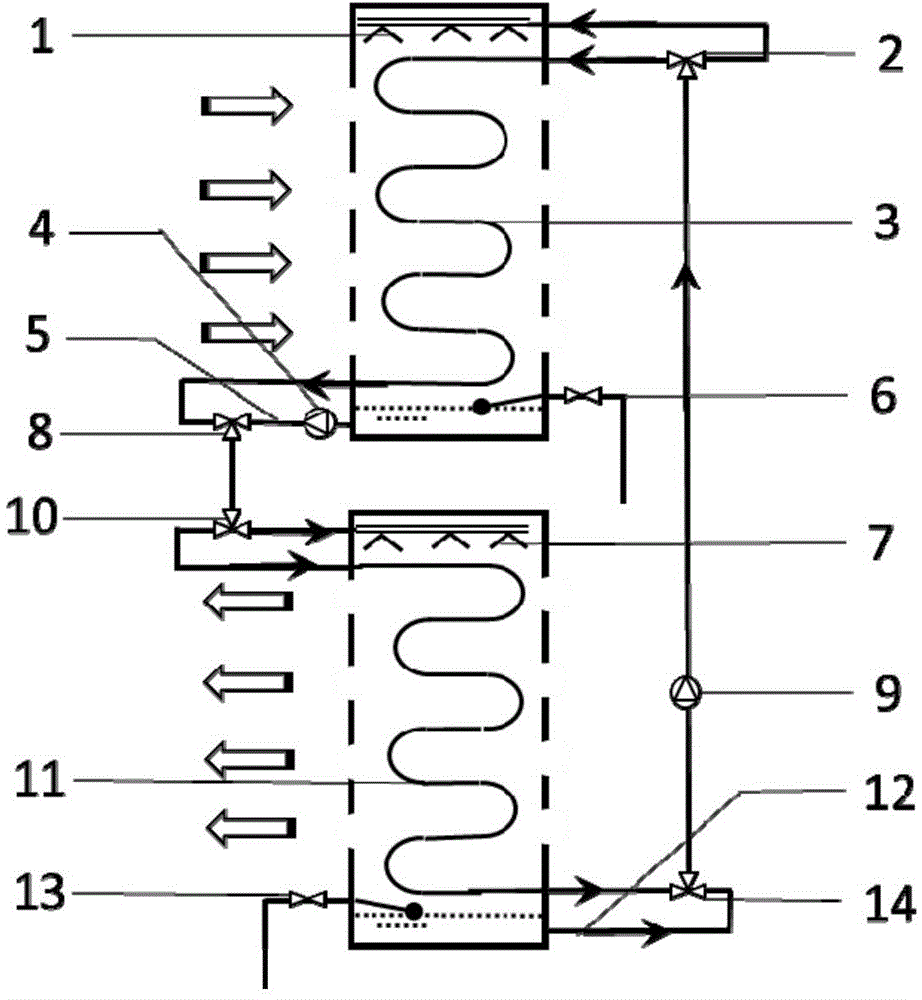

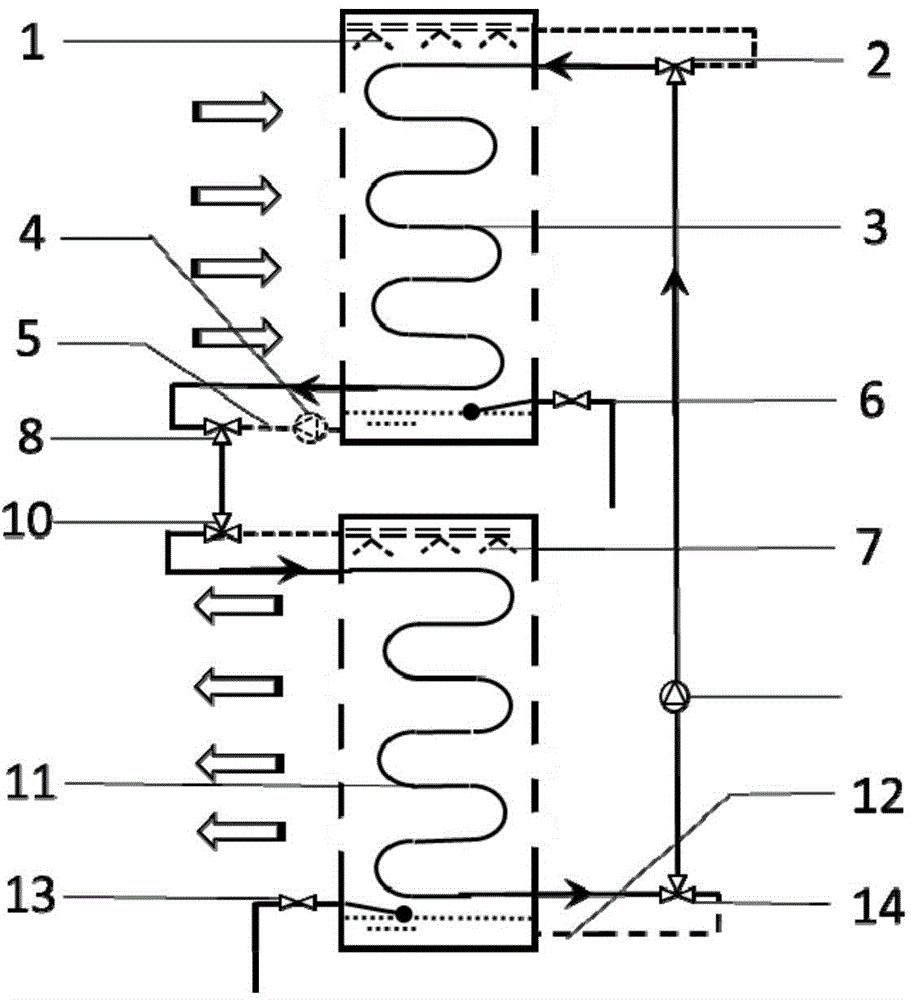

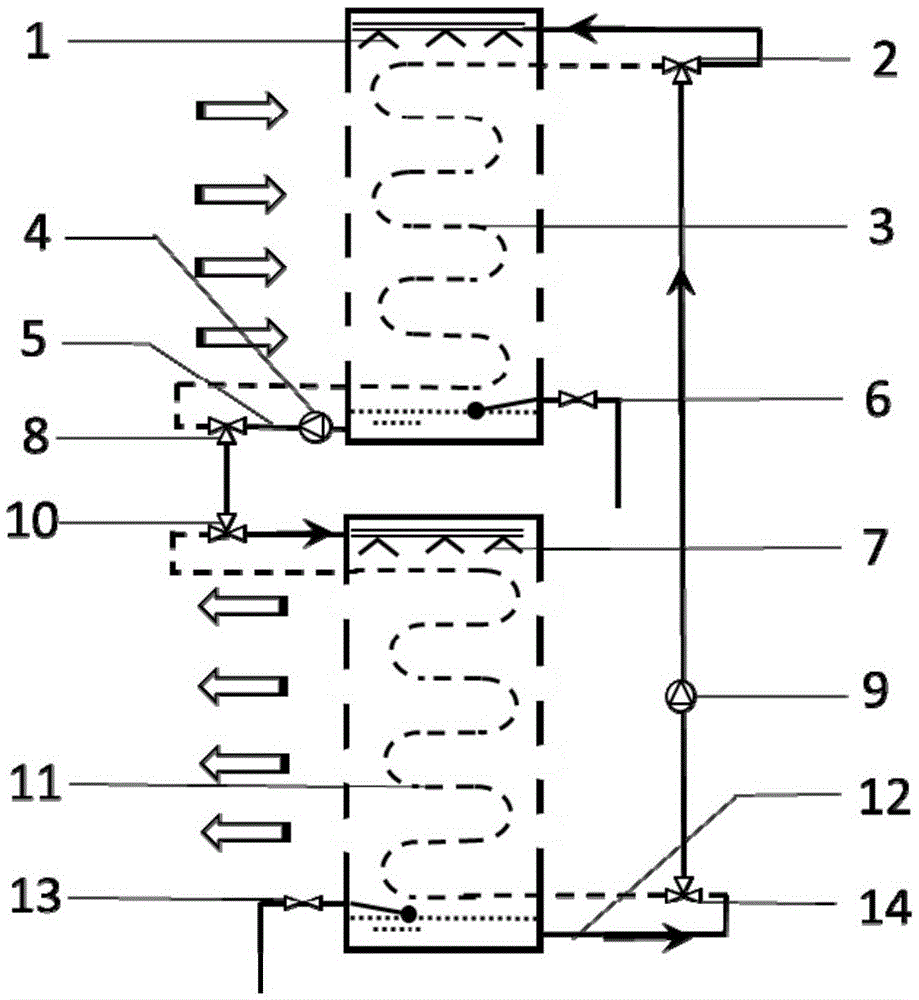

[0028] Structure, principle and mode of operation of the present invention are further elaborated below in conjunction with accompanying drawing:

[0029] The present invention comprises an exhaust side heat exchanger, an air inlet side heat exchanger, two circulation pumps and four three-way valves; the exhaust side and the air inlet side conduct heat exchange through liquid medium; The wind-side heat exchangers all contain spray assembly 1 or 7, heat exchange coil 3 or 11, and liquid storage tanks; each liquid storage tank has two outlets, respectively equipped with liquid outlet pipes 5 or 12 and maintenance liquid storage tanks. Fluid replenishment float valve 6 or 13 with stable liquid level in the tank; the first three-way valve 2 is installed on the inlet pipe of the heat exchange coil 3 on the air inlet side, and the second three-way valve 8 is installed on the inlet pipe of the heat exchange coil 3 on the air inlet side On the outlet pipeline, the third three-way valv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap