Digital control precision loading mechanism

A loading mechanism and digital control technology, applied in the field of mechanical testing technology and mechanical experiment, can solve the problem of inability to directly calibrate precision sensors, and achieve the effect of expanding the scope of application, flexibility, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

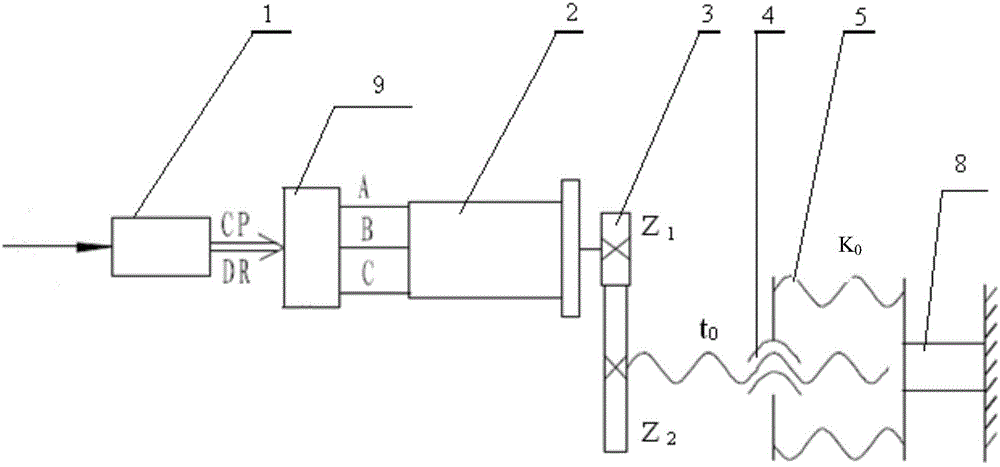

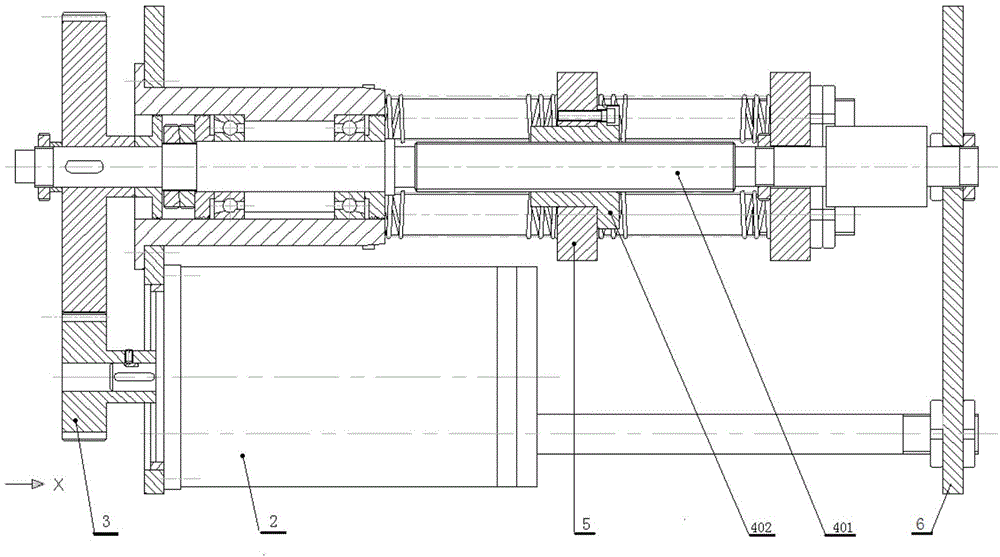

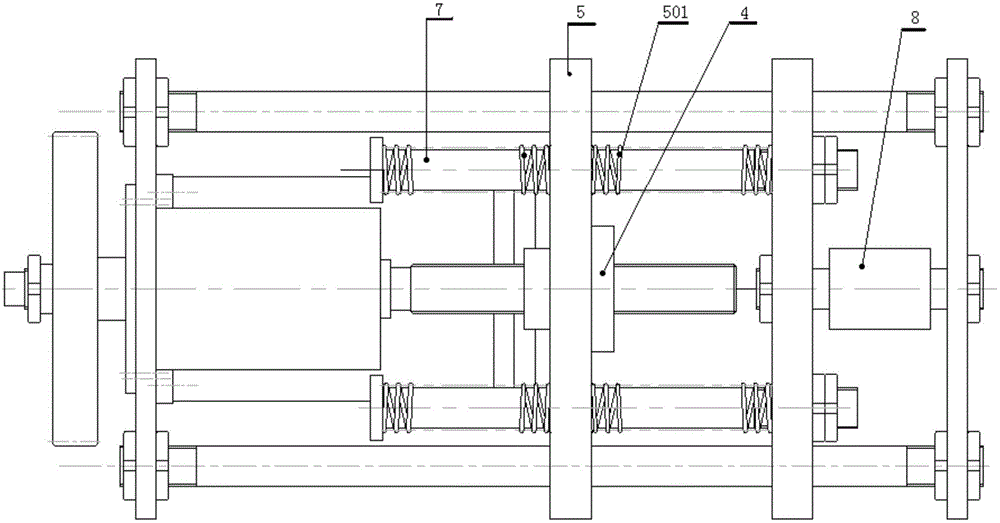

[0029] This embodiment provides a two-way tension / compression structure scheme, the digital control precision loading mechanism in this embodiment, such as Figure 1-3 As shown, it includes a controller 1, a motor 2, a transmission mechanism 3, a screw pair transmission mechanism 4 and a spring group actuator 5, and the screw pair transmission mechanism 4 in this embodiment can be a common sliding screw / nut pair, or It can be a ball screw / nut pair. The motor 2 and the screw pair transmission mechanism 4 are installed on the support plate 6 and located on the same side of the support plate 6. This structure makes the axial dimension of the precision loading mechanism compact.

[0030] The motor 2 drives the active part 401 of the helical auxiliary transmission mechanism to rotate through the transmission mechanism 3. Specifically, the transmission mechanism can be any one of gear transmission, worm gear / worm transmission, synchronous toothed belt transmission or coupling transmi...

Embodiment 2

[0045] This embodiment provides a kind of unidirectional tensile structure scheme: as Figure 4-5 As shown, the difference between it and Embodiment 1 is that a compression spring group is installed on one side (left side) of the nut. Or install a tension spring group on one side (right side) of the nut.

Embodiment 3

[0047] This embodiment provides a one-way compression structure scheme: such as Figure 6-7 As shown, the difference between it and Embodiment 1 is that a compression spring group is installed on one side (right side) of the nut. Or install a tension spring group on one side (left side) of the nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com