Unit cell PN junction and precise construction method thereof

A technology of PN junction and single cell, applied in the field of PN junction, can solve the problem of difficult realization of PN junction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

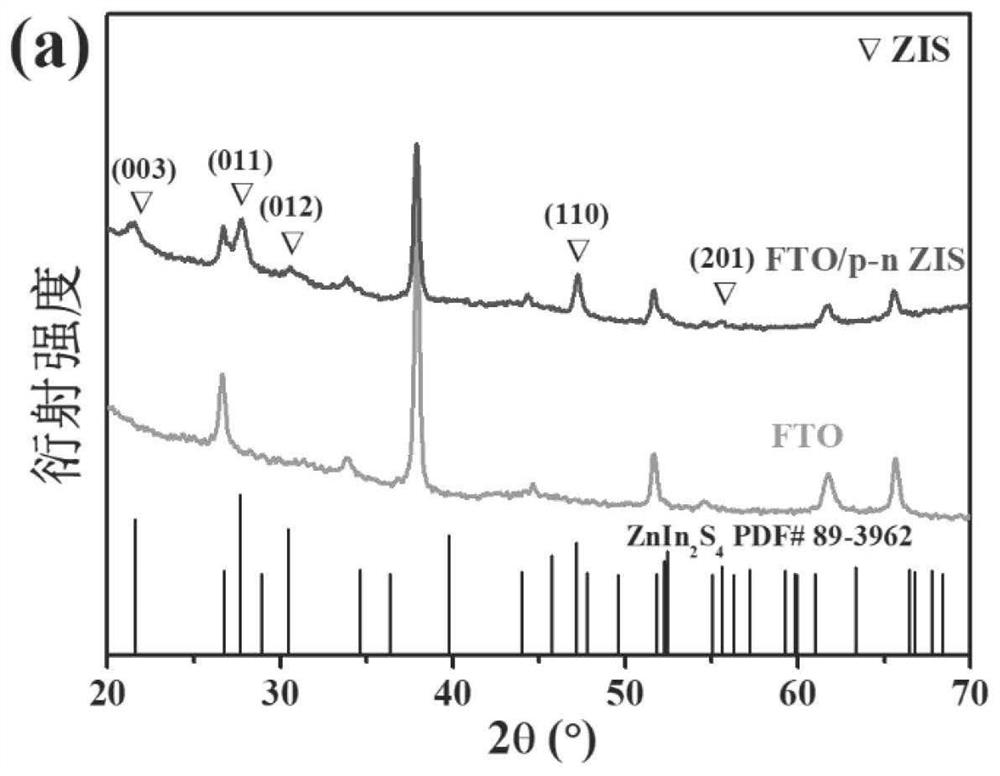

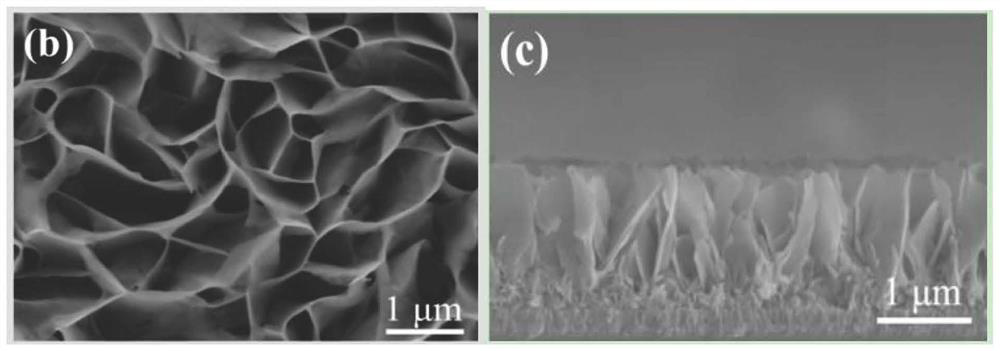

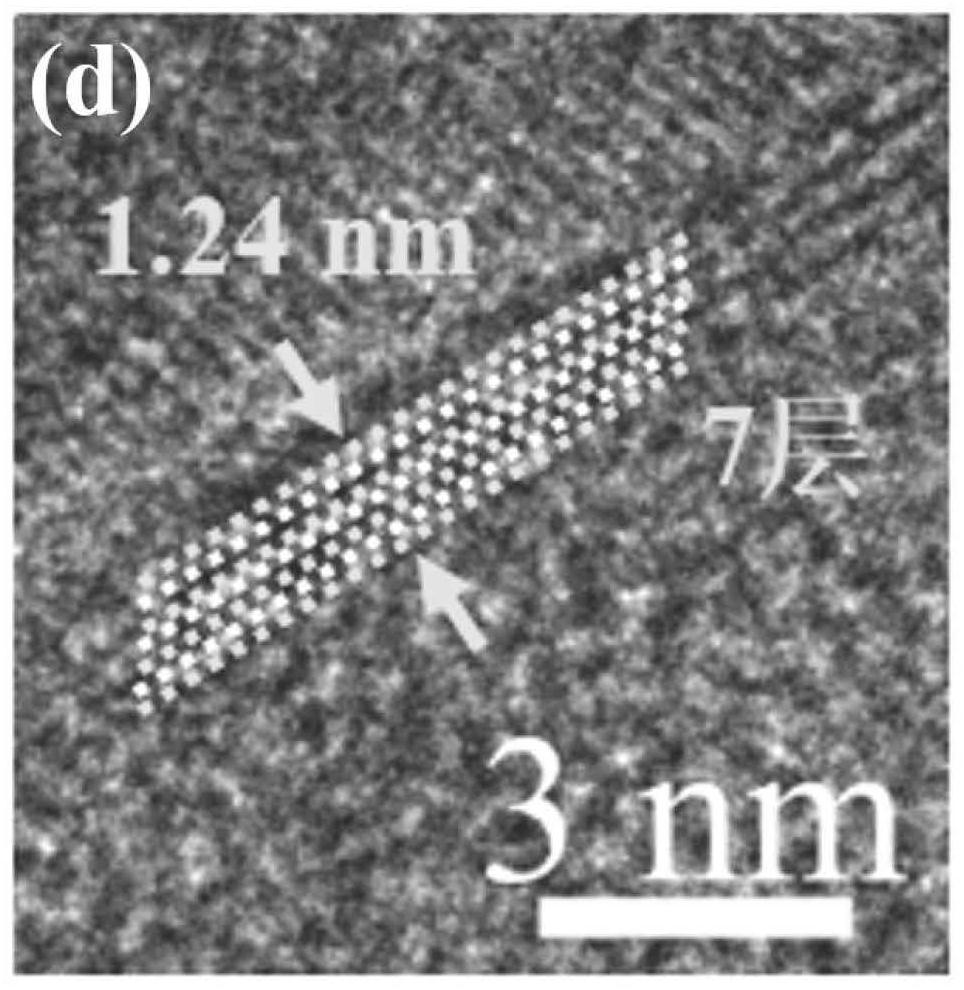

Embodiment 1

[0066] Fluorine-doped SnO 2 Conductive glass (conductive glass FTO) was continuously ultrasonicated in acetone, ethanol and deionized water for 30 minutes respectively, dried and set aside. Put zinc chloride, indium chloride and thiourea into a beaker according to the atomic ratio Zn:In:S=1:2:4, add an appropriate amount of deionized water and stir thoroughly to obtain a reaction solution. Then, put the dry conductive glass FTO into the polytetrafluoroethylene liner, slowly drop the reaction solution into the liner, the volume ratio of the conductive glass FTO to the reaction solution is 1:2, and the reaction solution does not completely immerse the conductive glass. Put the polytetrafluoroethylene liner into the autoclave, then put the autoclave into the oven, and react at 100°C for 24h. After the reaction was completed, the temperature was naturally cooled to room temperature. The reaction kettle was opened, and a film was formed on the conductive glass FTO. After the cond...

Embodiment 2

[0069] Fluorine-doped SnO 2 Conductive glass (conductive glass FTO) in concentrated H with a volume ratio of 3:1 2 SO 4 and H 2 o 2 Wash in the solution for 15 minutes, then ultrasonically clean in the solution for 5 minutes, dry and set aside. Zinc nitrate, indium sulfate and thioacetamide were put into a beaker according to the atomic ratio Zn:In:S=1:2:4, and an appropriate amount of deionized water was added for thorough stirring to obtain a reaction solution. Then, put the dry conductive glass FTO into the polytetrafluoroethylene liner, slowly drop the reaction solution into the liner, the volume ratio of the conductive glass FTO to the reaction solution is 1:10, and the reaction solution does not completely immerse the conductive glass. Put the polytetrafluoroethylene liner into the autoclave, then put the autoclave into the oven, and react at 200°C for 2h. After the reaction was completed, the temperature was naturally cooled to room temperature. The reaction kettl...

Embodiment 3

[0072] Fluorine-doped SnO 2 Conductive glass (conductive glass FTO) was cleaned in hydrofluoric acid and deionized water with a volume ratio of 1:10 for 15 minutes, then ultrasonically cleaned in the solution for 5 minutes, dried and set aside. Put zinc sulfate, indium sulfate and sodium thiosulfate into a beaker according to the atomic ratio Zn:In:S=1:2:4, add an appropriate amount of deionized water and stir thoroughly to obtain a reaction solution. Then, put the dry conductive glass FTO into the polytetrafluoroethylene liner, slowly drop the reaction solution into the liner, the volume ratio of the conductive glass FTO to the reaction solution is 1:6, and the reaction solution is not completely immersed in the conductive glass. Put the polytetrafluoroethylene liner into the autoclave, then put the autoclave into the oven, and react at 150°C for 15h. After the reaction was completed, the temperature was naturally cooled to room temperature. The reaction kettle was opened, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com